MANUEL D’UTILISATION « ASP 116 EVOLUTION »

Sprinte SAS, All rights reserved, including translation rights

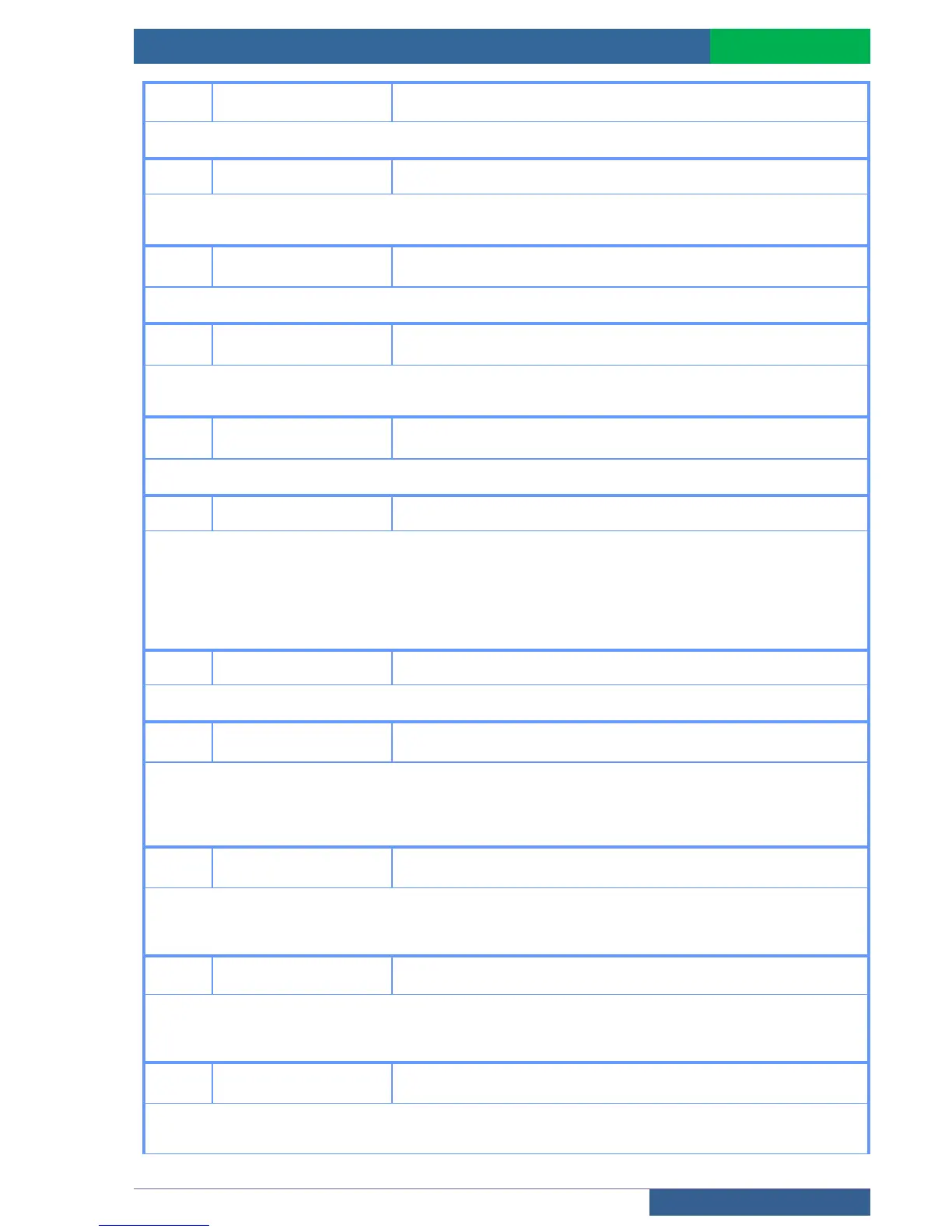

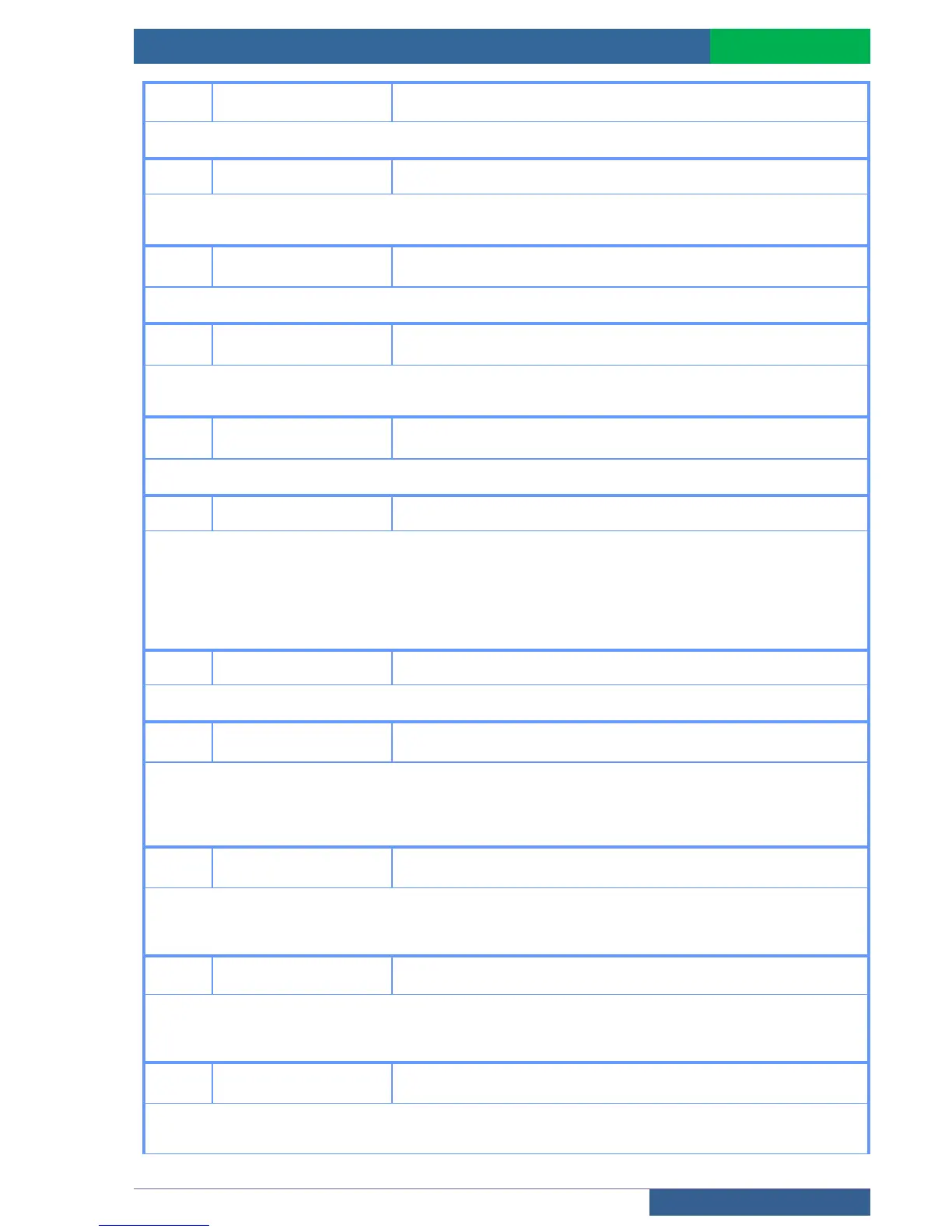

Braking too sudden or driving load

- Increase the deceleration time.

Loss of one phase at drive output

- Check the connections from the inverter to the motor.

- Check the power contactors

The main 400V power is not detected by the inverter

- Check the main power supply.

Motor not connected or motor power too low

- Check the connections from the inverter to the motor.

- Check the power contactors

Drive incorrectly supplied or a fuse blown or loss of one input phase

- Check the power connection and the fuses.

The inverter doesn’t working on control panel order

A fault is detected if the inverter is commanded and the RM input indicates that it is stopped.

- Check cabling of E2-CN10-I / 220SP

- Check the motor runs on starting,

- Check the motor runs in operation

Caution, the RM fault may be detected during lock micro-cutout during movement (locks incorrectly adjusted)

Power grid voltage is too low

- Check the power connection and the fuses.

The braking resistor is under excessive stress

- Augmenter la distance de décélération.

- Vérifier la valeur de la résistance.

- Mettre un volant d’inertie moins lourd

- Contrôler l’équilibrage

Déclenchement par courant moteur trop élevé

- Check the thermal protection of the motor

- Check the motor load.

- Check the size of the resistor and wait for it to cool down.

- Check the size of the load/motor/drive.

- Decrease the switching frequency.

- Wait for the motor to cool before restarting

Inverter temperature too high

- Check the motor load, the drive ventilation and the ambient temperature.

- Wait for the drive to cool down before restarting.

Loading...

Loading...