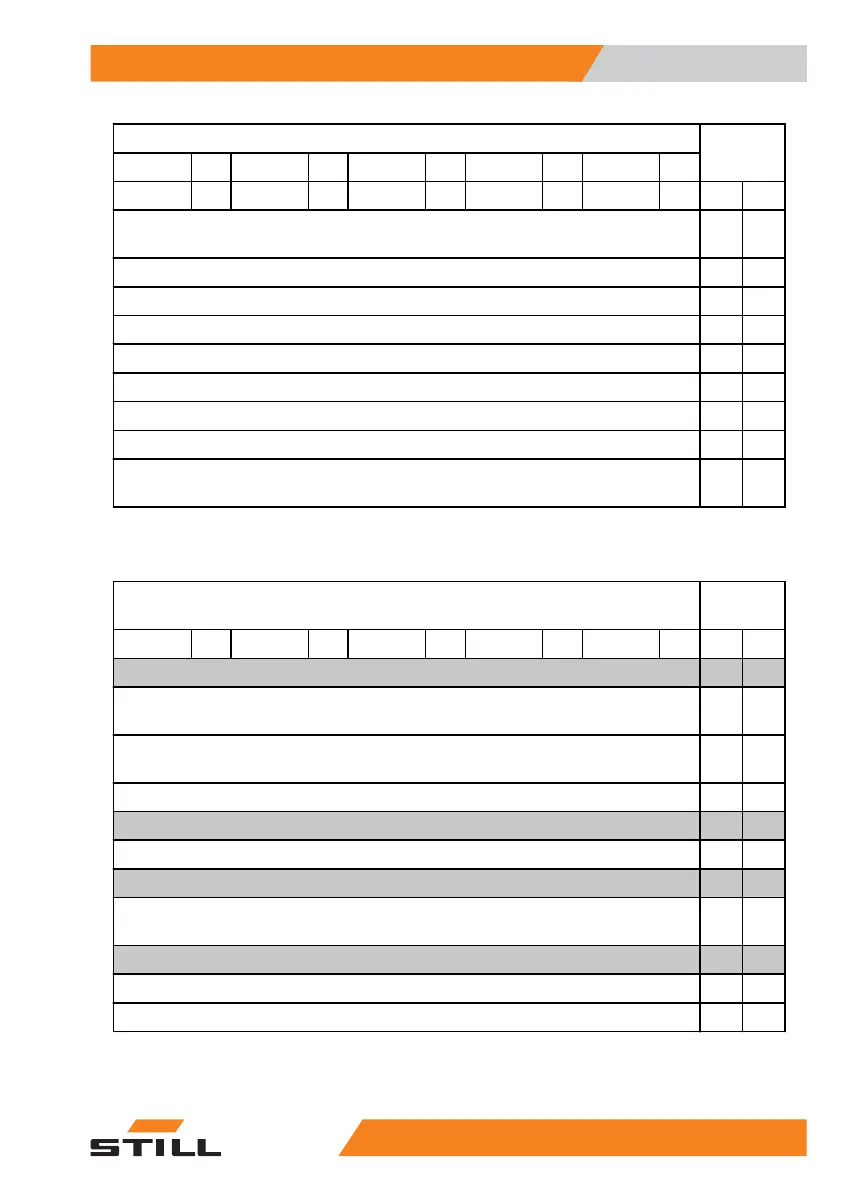

At operating hours

1000 h

2000 h

3000 h

4000 h

5000 h

6000 h

7000 h

8000 h

9000 h

10000 h

Carried

out

Lift mast rollers: lubricate with all-purpose grease. If necessary, install lubricating

nipples.

Lift mast rollers: check the condition and check the setting.

Guide elements: check the lateral play.

Guide elements: lubricate with all-purpose grease.

Load fork: check the condition and function of the latches.

Load fork: visually inspect for bends, measure if necessary.

Load fork: if you suspect there are cracks, check using the dye penetrant procedure.

Adjustable fork: lubricate sliding surfaces with all-purpose grease.

Swivel drive: check that the eight screws between the swivel drive and the front end

are securely fastened.

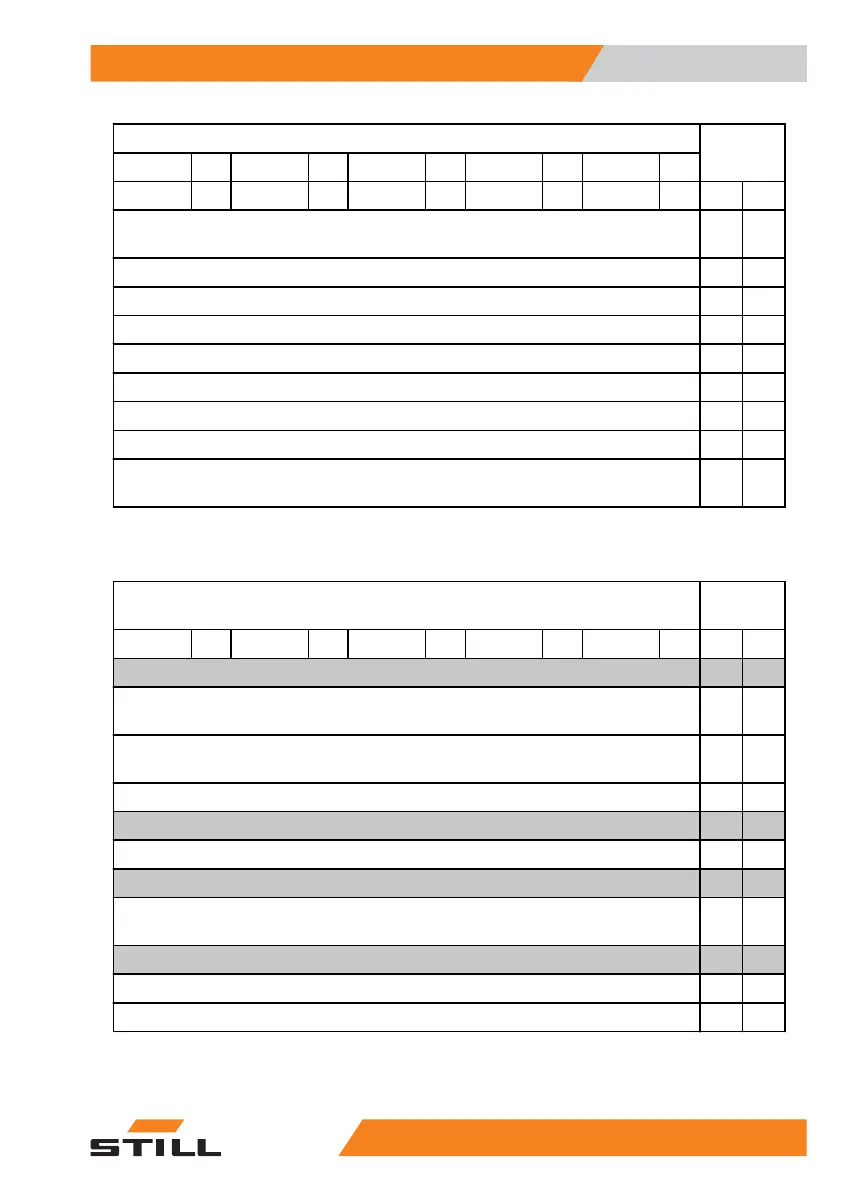

2000-hour maintenance schedule

At operating hours

2000 h

4000 h

6000 h

8000 h

10000 h

Carried

out

Gearbox

Gearbox: visually inspect the shaft/hub connection between the traction motor and

gearbox and clean the connection if necessary.

Gearbox: add new lubricant to the shaft/hub connection between the traction motor

and gearbox. Refer to the lubricant overview.

Gearbox: perform an oil change (every 4000 hrs).

Hydraulics

Hydraulic system: oil change.

Chassis, bodywork and fittings

M24 screw connection between the welded chassis, the rear of the cast and the col-

lision protection: check for secure attachment with a torque of Ma = 660 Nm.

Final tasks

Test drive: check all functions and special functions according to the order.

Service adhesive label: attach.

Regular care and maintenance

5

2000-hour maintenance schedule

1035231 804 2502 EN - 04/2020

Loading...

Loading...