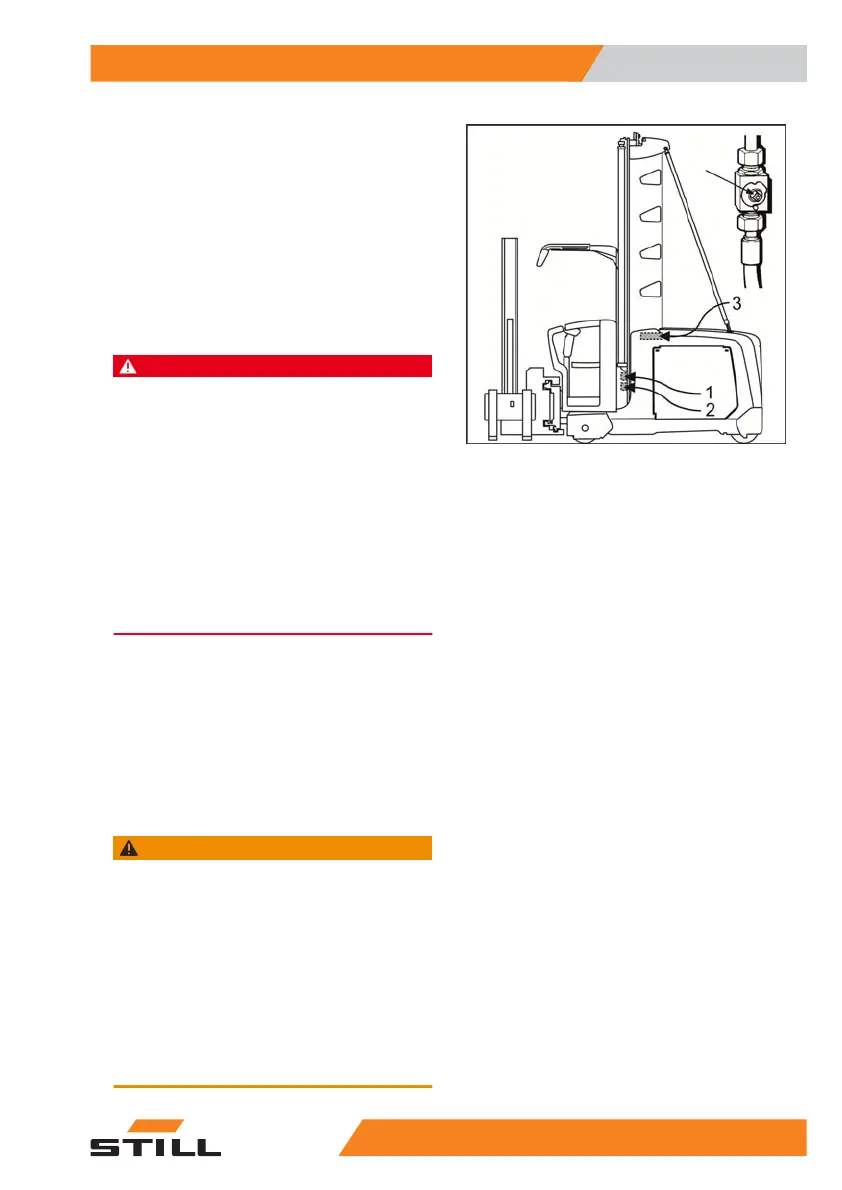

Securing the load support

In order to secure the load support against

lowering during maintenance work, the lower-

ing movement can be locked by closing the

shut-off valves. A notch in the block section in-

dicates the valve position.

●

The notch is pointing in the direction of the

connected line = flow open

●

The notch is at a right angle to the direction

of the connected line = flow blocked

DANGER

Risk from lowering of the lift mast or driver's cab

– The pressure in the hydraulic system must be re-

leased before any work is carried out on it. The

load support must also be lowered to the ground.

– Before a person can go underneath the raised

driver's cab, an additional mechanical safety de-

vice must be installed. For example, fit a suitably

strong brace around the bridge pieces on parts of

the lift mast or place a suitably strong jack stand

underneath the driver’s cab.

– Lock all existing shut-off valves. There is a valve

for each main lift cylinder (1), one for each free lift

cylinder* (2) and two additional valves for the hy-

draulic lines for the attachment (3).

*Option

Emergency operation

If the entire truck control unit or part of it fails,

the industrial truck can be moved out of the

working area by means of the relevant emer-

gency operation mechanism.

WARNING

– Only tow at creep speed

– There must always be an operator in the industrial

truck that is being towed.

– There must not be anyone in the danger area of

the trailer train.

– In order to prevent strong lateral forces and there-

fore the risk of tipping, always leave plenty of

space when driving round corners.

– The vehicle used for towing must always be driv-

en carefully and be able to brake gently and in

good time.

Operation

4

Emergency operation

855231 804 2502 EN - 04/2020

Loading...

Loading...