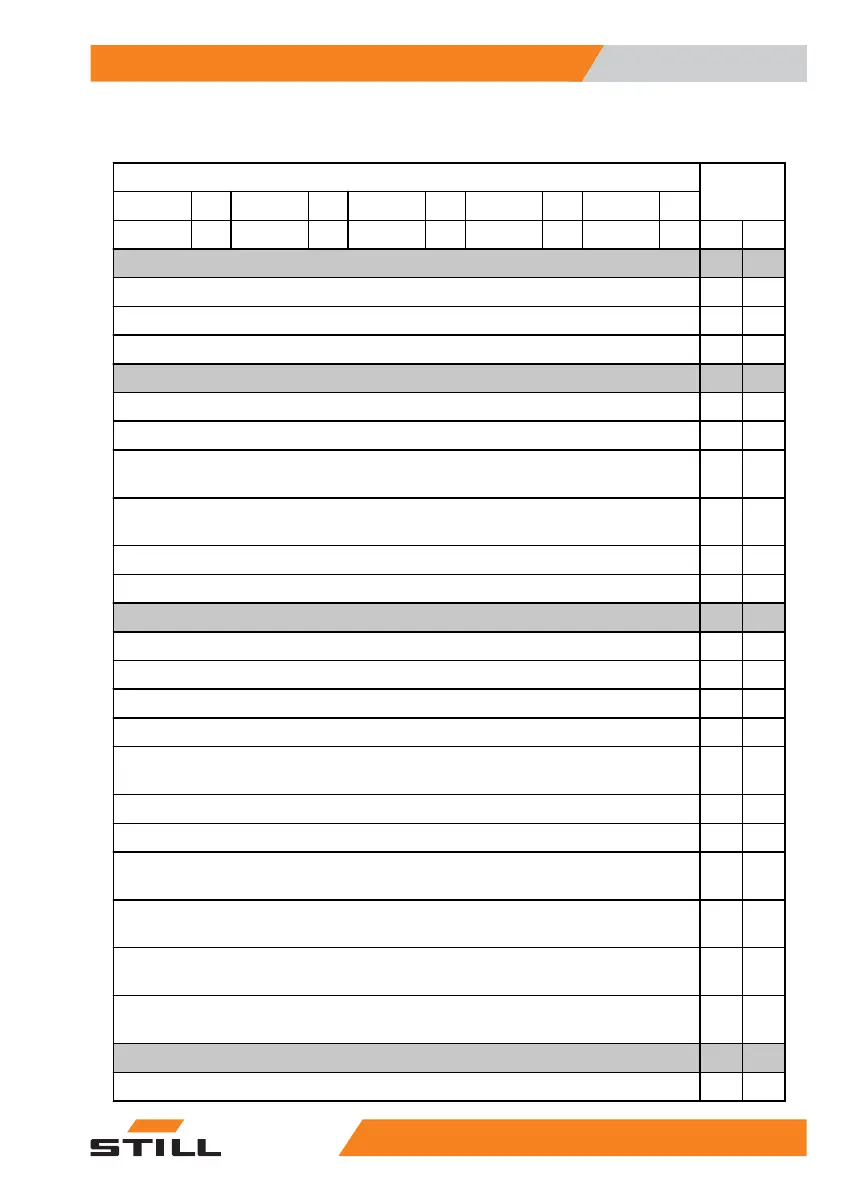

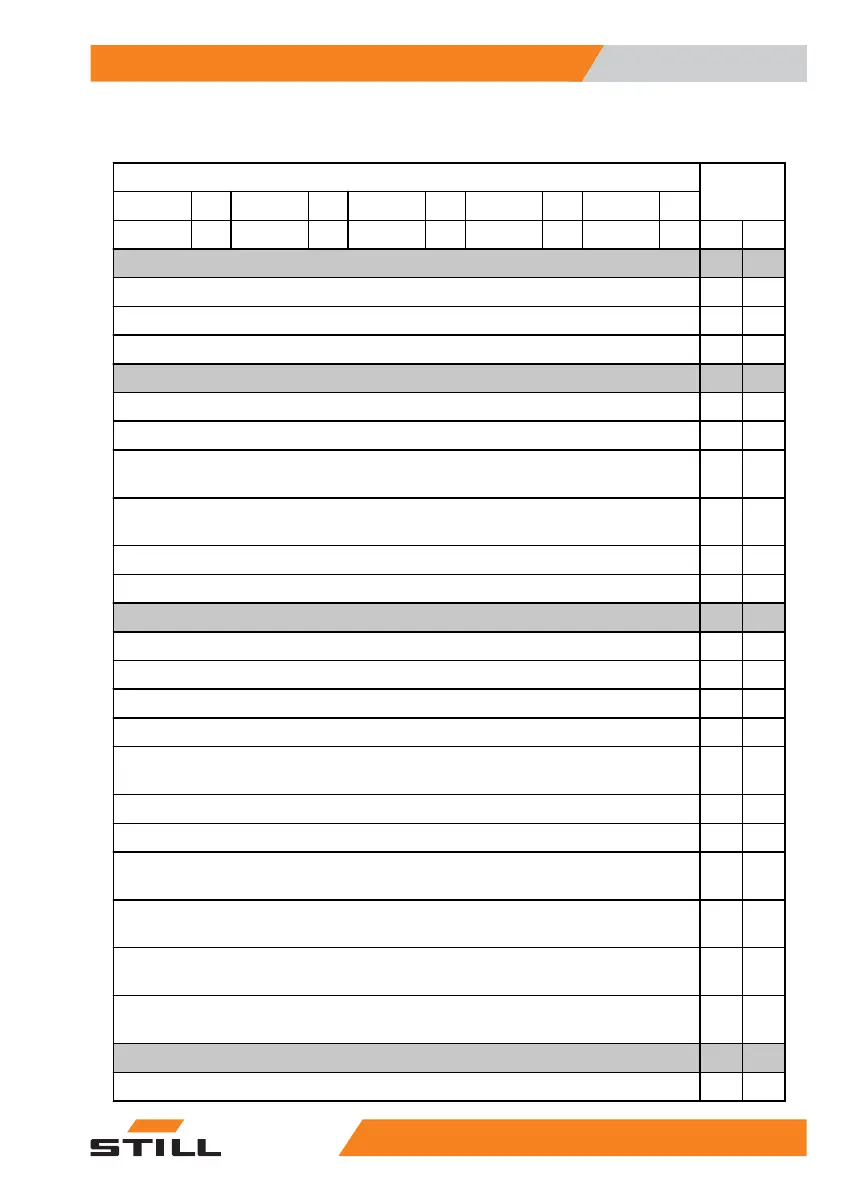

1000-hour maintenance schedule

At operating hours

1000 h

2000 h

3000 h

4000 h

5000 h

6000 h

7000 h

8000 h

9000 h

10000 h

Carried

out

Preparatory tasks

Industrial truck: clean or have it cleaned by the operating company.

Nameplate: identify the industrial truck.

Controller: read out the operating hours.

Gearbox

Gearbox: check for noise and leakages.

Gearbox: check the oil level, top it up if necessary.

Gearbox: first oil change after 1000 operating hours and every 4000 operating hours

thereafter.

Drive unit: check the tightness of the screw connection to the chassis (ensure the

appropriate torque).

Traction motor bearings: check for operating noise.

Traction motor bearings: replace if necessary.

Chassis, bodywork and fittings

Bearing points and joints: check and lubricate.

Doors, flaps and covers: check function.

Doors, flaps and covers: check the mounting and condition.

All moving parts: lubricate with a suitable lubricant.

Overhead guard: visually inspect the weld seams; use a dye penetrant procedure if

you suspect there are cracks.

Overhead guard: visually inspect for damage and deformations.

Rail switches: check the function and condition.

Support screws in the chassis: check the setting according to the specifications on

the nameplate. Adjust as necessary.

Battery compartment door and battery compartment hood: check and adjust as nec-

essary.

Battery compartment door and battery compartment hood: check and adjust as nec-

essary.

Battery compartment: check that the battery is securely positioned and check side

stops on the battery.

Chassis frame

Drive wheel: check the condition and check for wear and any foreign objects.

Regular care and maintenance

5

1000-hour maintenance schedule

995231 804 2502 EN - 04/2020

Loading...

Loading...