6-34 POWER UNIT

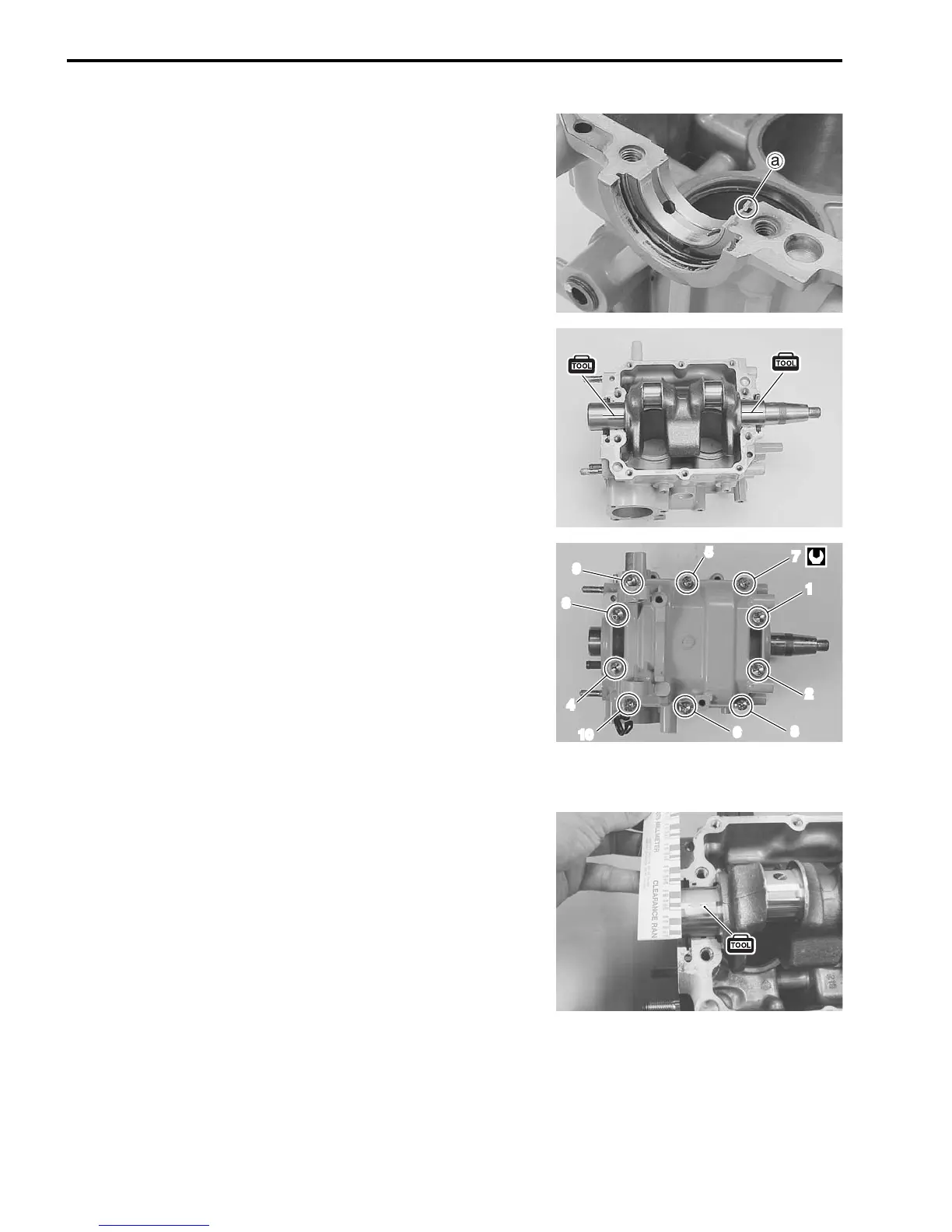

2. Install crankshaft main bearing to cylinder and crankcase.

NOTE:

• Reassemble each bearing to its original position.

• Align the tab a of bearing with notch in cylinder and crank-

case.

• Do not apply oil to bearing.

3. Install crankshaft to cylinder.

4. Place a piece of Plastigauge across full width of bearing

(parallel to crankshaft) on journal.

Do not place Plastigauge over oil hole.

09900-22301: Plastigauge

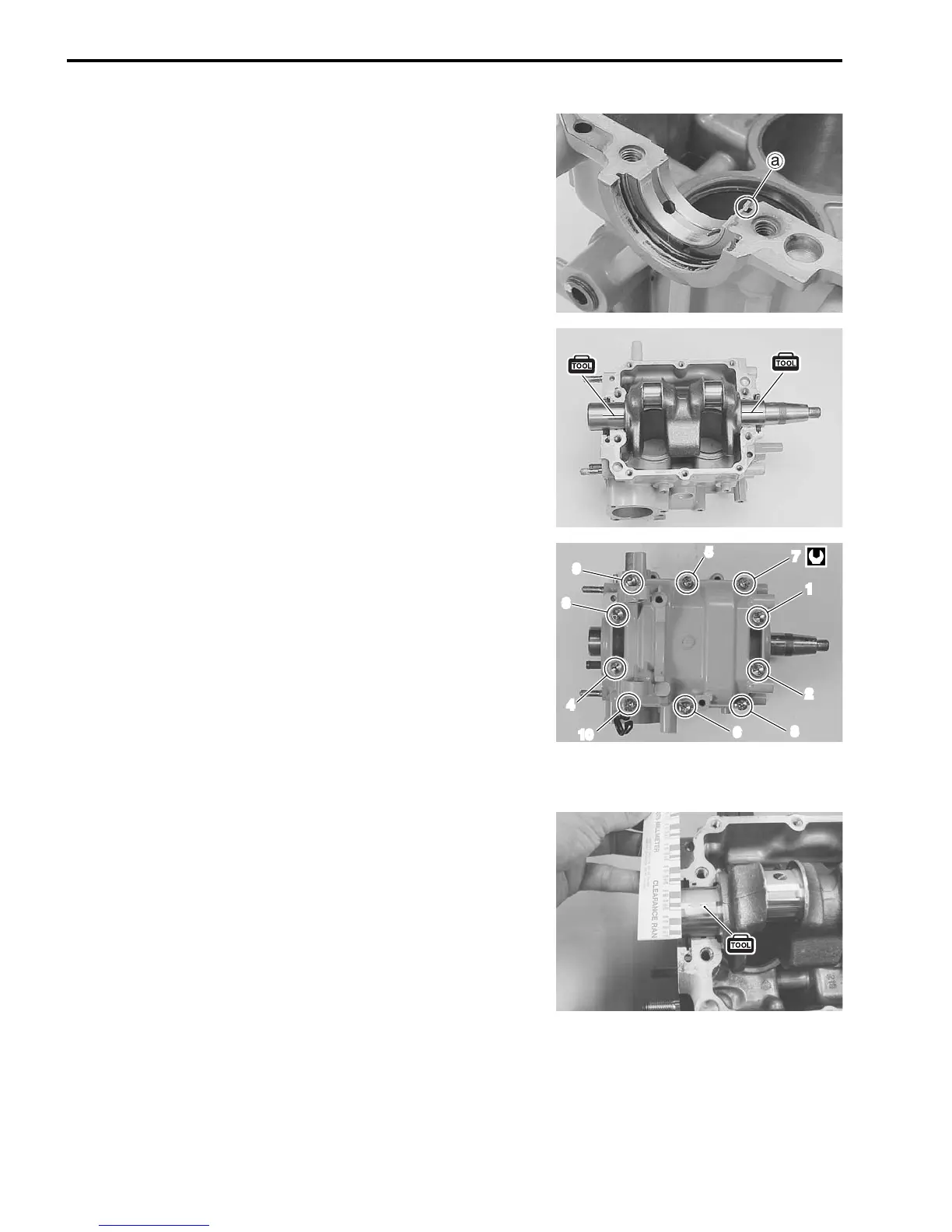

5. Install crankcase (with the bearing) to cylinder.

6. Apply engine oil to crankcase bolts and tighten bolts to the

specified torque following the order indicated.

Crankcase bolt:

6 mm 14 N·m (1.4 kg-m, 10.0 lb-ft)

8 mm 25 N·m (2.5 kg-m, 18.0 lb-ft)

NOTE:

• The crankcase must be torqued to specification in order to

assure proper compression of Plastigauge and accurate read-

ing of clearance.

• Do not rotate crankshaft while Plastigauge is installed.

7. Remove crankcase from the cylinder.

8. Measure the compressed plastigauge width at its widest

point.

NOTE:

For bearing replacement, see the “SELECTION OF MAIN

BEARING” section on page 6-35.

7

1

2

8

6

4

10

3

9

5

Loading...

Loading...