LOWER UNIT 8-23

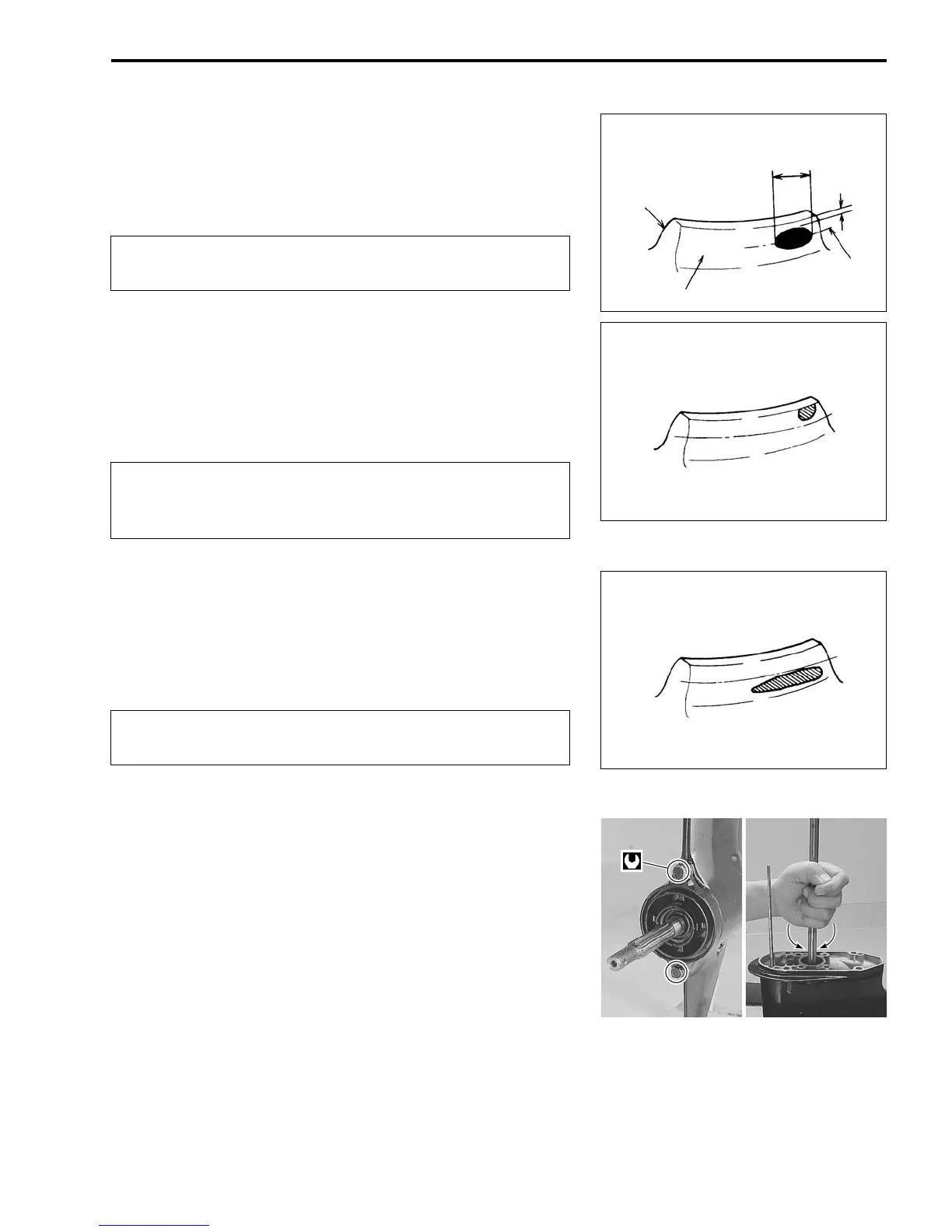

Optimum tooth contact

The optimum tooth contact is shown at right.

A shim adjustment may be necessary to obtain this contact pat-

tern.

Example (1)

Incorrect topside toe contact:

Correction measures:

• Decrease thickness of forward gear back-up shim.

• Slightly increase pinion gear back-up shim thickness.

Example (2)

Incorrect bottom side toe contact:

Correction measures:

• Increase thickness of forward gear back-up shim.

• Slightly decrease pinion gear back-up shim thickness.

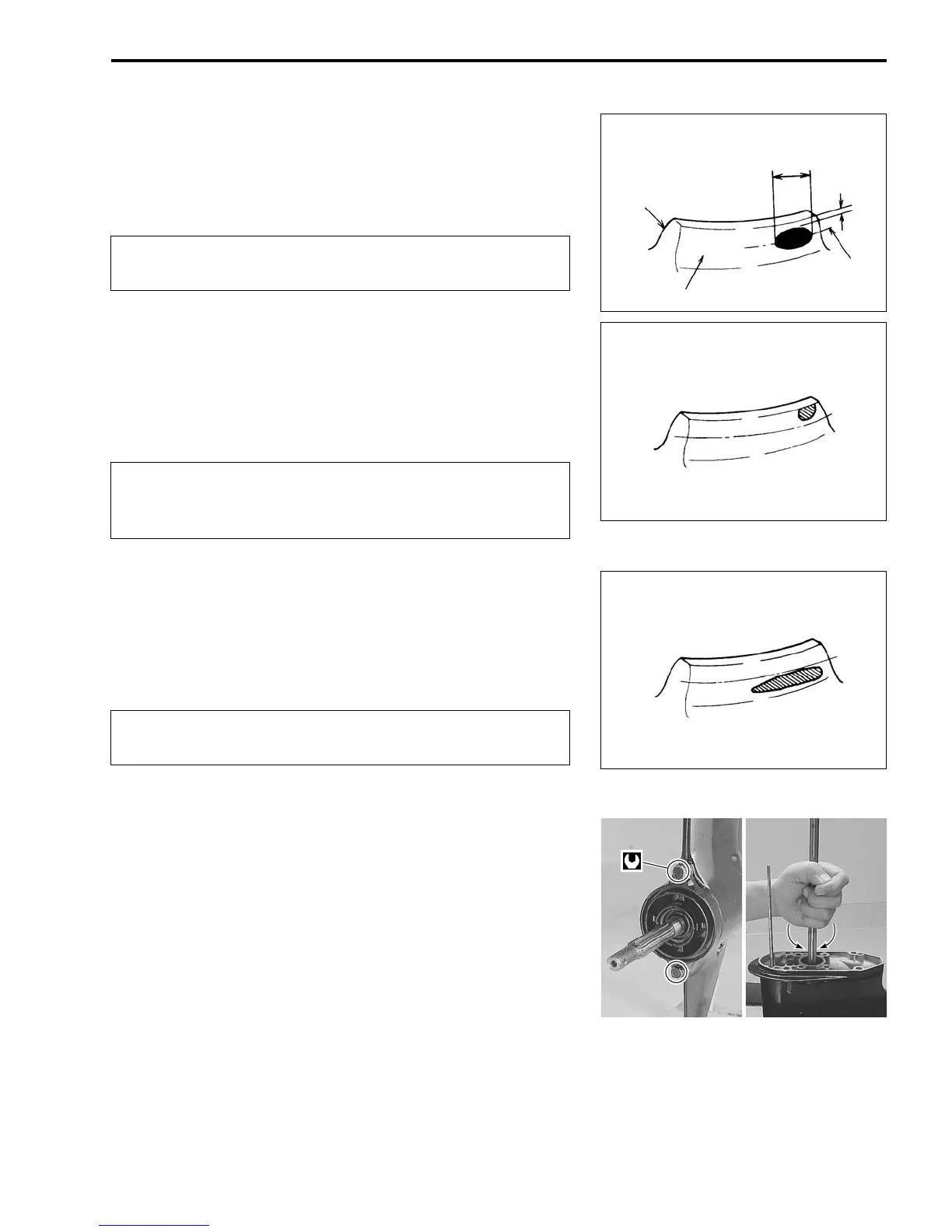

PINION GEAR/REVERSE GEAR

1. Check the amount of backlash between the pinion gear and

forward gear. (See page 8-21.)

2. Install the propeller shaft/bearing housing assembly to the

gearcase.

Propeller shaft bearing housing bolt:

8 N·m (0.8 kg-m, 6.0 lb-ft)

3. Check the amount of backlash by slightly rotating the drive-

shaft by hand.

4. Backlash should not be less than when checked step (1).

If backlash is less, reduce the reverse gear back-up shim

thickness.

Gear backlash should be checked when increasing or

decreasing shim thickness to adjust tooth contact.

Do not set tooth contact in this position (top side toe

contact). Damage and chipping of forward and pinion

gear may result.

Do not set tooth contact in this position (bottom side

toe contact). Chipping of pinion gear may result.

Optimum tooth contact

HEEL

Convex side

Approx. 1/3 of

tooth width

Approx.

1 mm

TOE

HEEL

TOE

EXAMPLE OF INCORRECT

Top side toe contact

Example (1)

EXAMPLE OF INCORRECT

Bottom side toe contact

HEEL

TOE

Example (2)

Loading...

Loading...