6-26 POWER UNIT

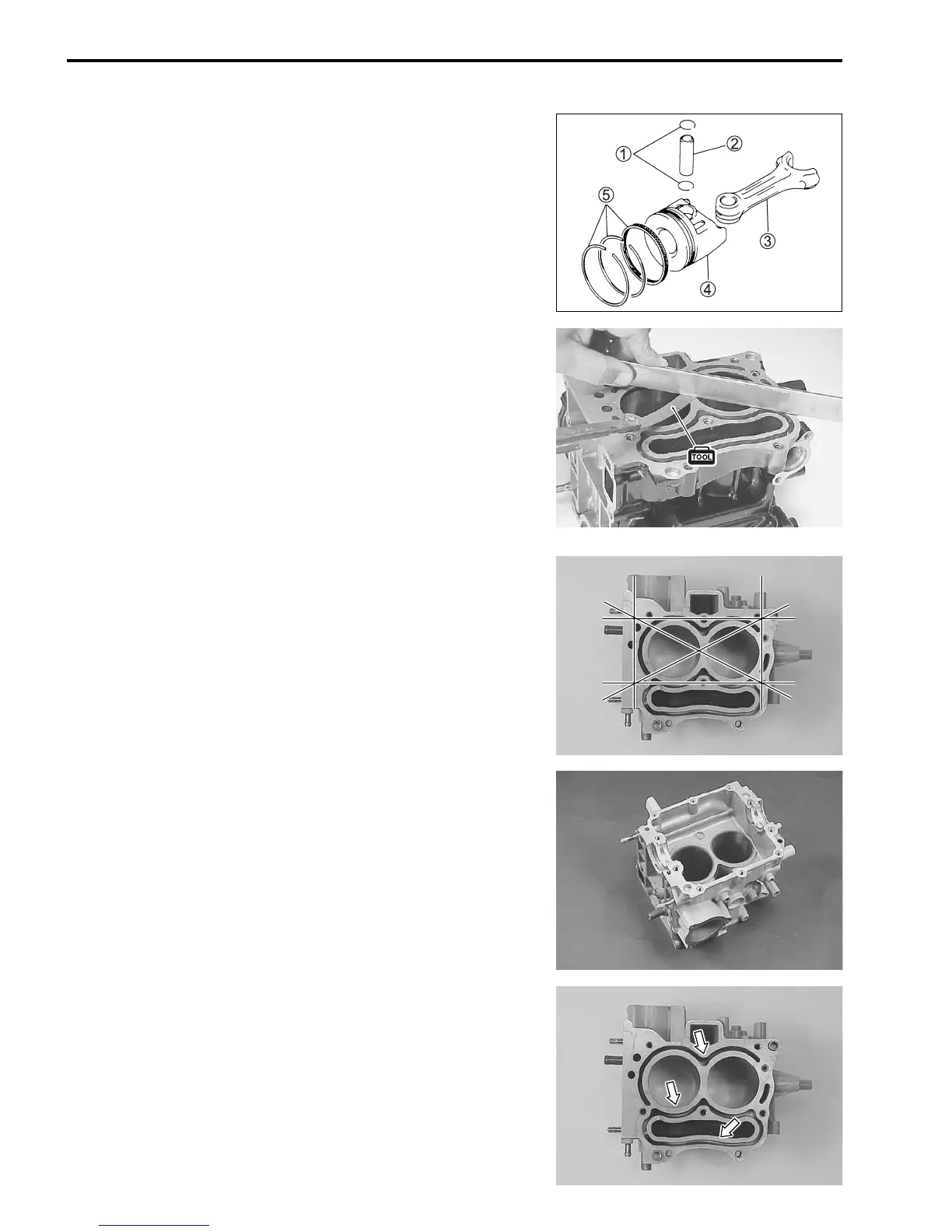

11. Remove piston pin circlips 1.

12. Remove piston pin 2 from conrod 3.

13. Remove two compression rings (top and 2 nd) and oil ring 5

from piston 4.

NOTE:

Install the 1 st ring to piston with its original direction.

There is no I.D. mark on standard size 1 st ring.

INSPECTION/SERVICING

NOTE:

If excessive wear, cracks, defective or other damage is found on

any component, replace component.

CYLINDER/PISTON

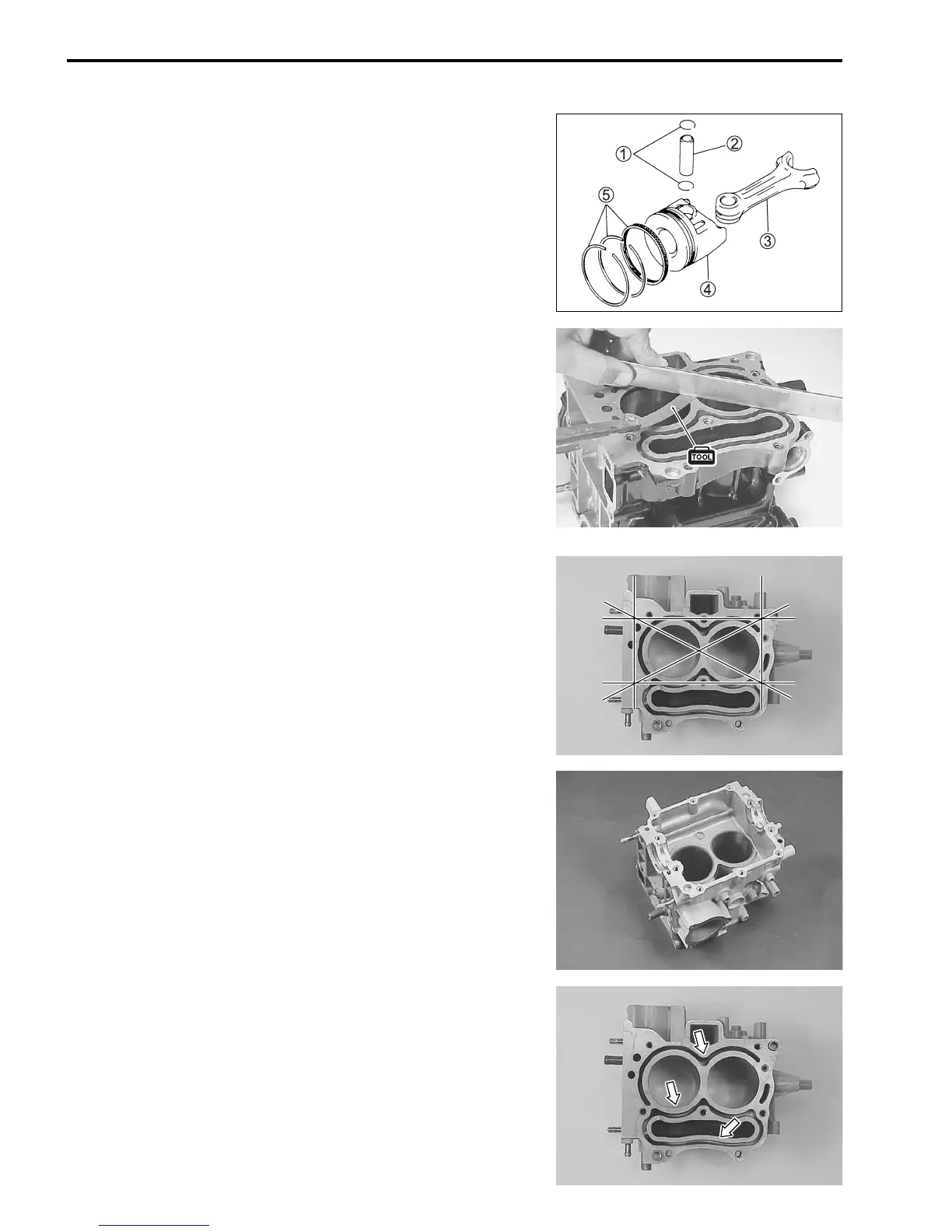

Cylinder distortion

Using a straightedge and thickness gauge, measure cylinder

distortion (gasketed surface) at a total of six (6) locations as

shown.

09900-20803: Thickness gauge

Service limit: 0.05 mm (0.002 in)

If measurement exceeds service limit, resurface or replace cylin-

der.

NOTE:

The cylinder can be resurfaced, using a surface plate and #400

grit wet sandpaper. Move the cylinder in a figure eight pattern

when sanding.

Water jacket

Check water jackets.

If clog or obstruction is found, clean the water jacket.

Loading...

Loading...