Page 33 of 957.10-00110b_en

Machine description

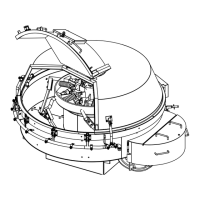

4�3�1 Mixing tank

The mixing tank is a ring trough with a mixer frame, made of steel sheet. Both the oor and the

walls of the trough are protected by means of replaceable wear liners, which are available in

various hardness grades.

4�3�2 Protective hood

The entire mixer and mixing chamber are covered by a steel sheet hood. One part of this is

xed and the other part can be swung open for servicing and cleaning work. The position of

the inlet nozzle and venting nozzle on the xed part can be decided on an individual basis. The

moveable part, which does not have any nozzles, can have one or more folding segments that

are secured with quick fasteners.

If the segment is opened when the machine is running, a safety sensor cuts o the mixer drive.

Depending on the size of the folding segment, it is opened manually or with a lifting aid.

An inspection ap with a wire mesh allows you to look into the mixer while it is working.

A scraper located in the stationary hood part cleans the central rotor cover of residue (option-

al).

4�3�3 Drive technology

The drive is carried out by a transmission with anged motor.

4.3.3.1 Motor thermal protection device

The drive motors used by TEKA are intended for connection to a thermal protection device.

This takes place using PTC sensors (positive temperature coecient thermistors) that are con-

nected in series and are located directly in the motor winding.

The measured DC voltage (test voltage) here is ≤ 2.5 V.

The response temperature is chosen so that the PTC thermistor becomes highly resistive as

soon as the maximum permitted operating temperature of the motor is exceeded.

The evaluation unit (protective device) to be connected then causes the power contactor of the

motor to cut o.

The machine can be switched on only once the motor has cooled to the permitted temperature.

The connection to the PTC thermistors takes place directly in the motor terminal box or in the

machine terminal box depending on the design.

If TEKA does not deliver the entire electrical control system for the machine, the PTC tripping

unit must be provided and installed by the customer.

Caution! Do not apply an external voltage to the PTC thermistors�

Loading...

Loading...