Page 34 of 95

7.10-00110b_en

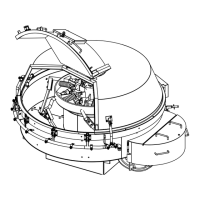

Machine description

4�3�4 Rotor and mixing tools

The robust rotor case contains the spring-mounted mixing arms in dierent positions in relation

to the mixed material as well as the wall scrapers.

The mixing arms are mounted in greased bushings that can be optionally supplied with grease

using a central lubrication system.

The mixing paddles, wall scrapers, and wear sleeves to protect the bottom of the mixing arms

are made from wear-resistant hard cast iron and can be given a carbide coating in extreme

wear conditions if desired.

4�3�5 Discharge system and hydraulics

The mixer discharge is a compact unit in the mixing trough oor.

The segmented discharge slide is actuated hydraulically by means of a swivel drive, is electri-

cally controlled, and can be placed into any desired opening position.

The internally positioned pivot point allows as large a discharge opening as possible to enable

fast, residue-free discharge.

Optionally, a manual pump can be mounted for the emergency opening of the discharge unit in

the case of a power outage, for example.

Up to three discharge units can be integrated.

The discharge unit is surrounded by a discharge protector.

The discharge slide is actuated by means of an oil pump that is ange-mounted to the trans-

mission and driven by the mixer motor.

A separate oil supply unit is available as an optional extra.

4�3�6 Special equipment

If desired, the mixer can be tted with other accessories.

● Mixer discharge hopper/transition piece

● Additional discharge

● Water dosing unit/uid dosing unit

● Steam supply

● Additional inspection ap in mixer protective hood

● Additional folding segment with safety limit switch in mixer protective hood

● Manual winch for folding up the folding segments in the protective hood

● Carbide-tipped mixing tools

● Low-nickel design of wear plates and mixing tools

● Central lubrication system for mixing arm bearings

● Separate oil supply unit

● Dust-tight discharge protector

● Lining of wear plates of trough oor

● Sealing from central section

● Scraper for discharge slide

● Scraper for crimp ring

● Scraper for rotor cover

Loading...

Loading...