Page 78 of 95

7.10-00110b_en

Maintenance

Approx.oilllquantities:

THZ 375 / 500 18 litres

THZ 750 20 litres

THZ 1125 21 litres

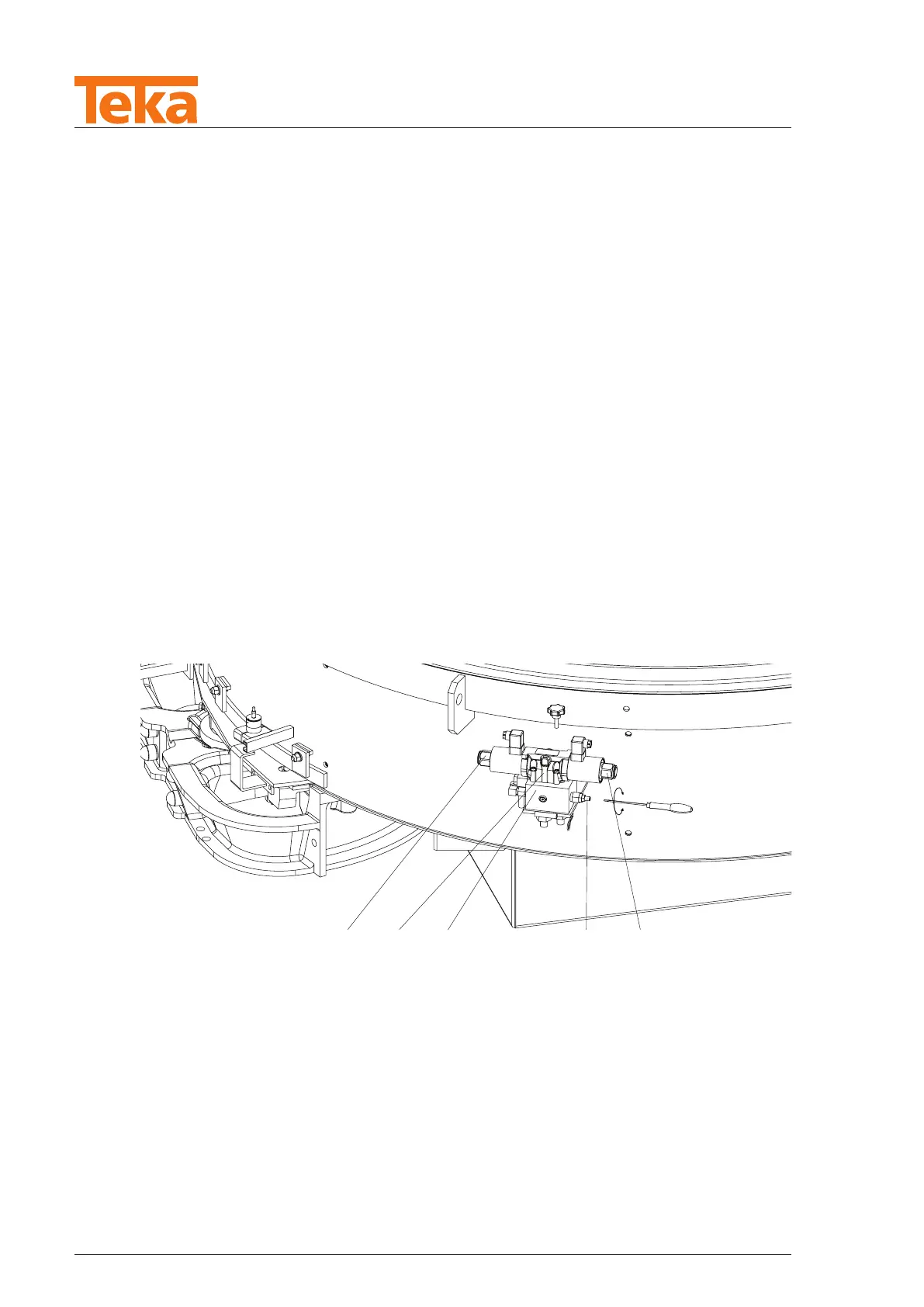

10�2�3 Checking the discharge opening pressure

● If necessary, screw a pressure gauge (G ¼") into the baseplate (5) of the

directional valve (4).

● With the mixer running, manually move the discharge slide by pressing in the control

piston valve (3) to the right or left up to the stop.

● Read the pressure: Setting pressure value: 100 bar (max. 125 bar)

10�2�4 Pressure regulation (if required)

● Remove the plastic cap from the pressure relief valve (6).

● Undo the hexagonal lock nut (under the cap).

● Turn the adjustment screw with a screwdriver

(to the right "+" = pressure increase, to the left "-" = pressure reduction)

until the setting pressure is reached.

● Tighten the lock nut.

● Replace the cap.

Fig. 59: Discharge hydraulic pressure adjustment

1 Solenoid coils for directional control valve

2 Directional control valve

3 Baseplate

4 Pressure relief valve with cover cap

Loading...

Loading...