Page 77 of 957.10-00110b_en

Maintenance

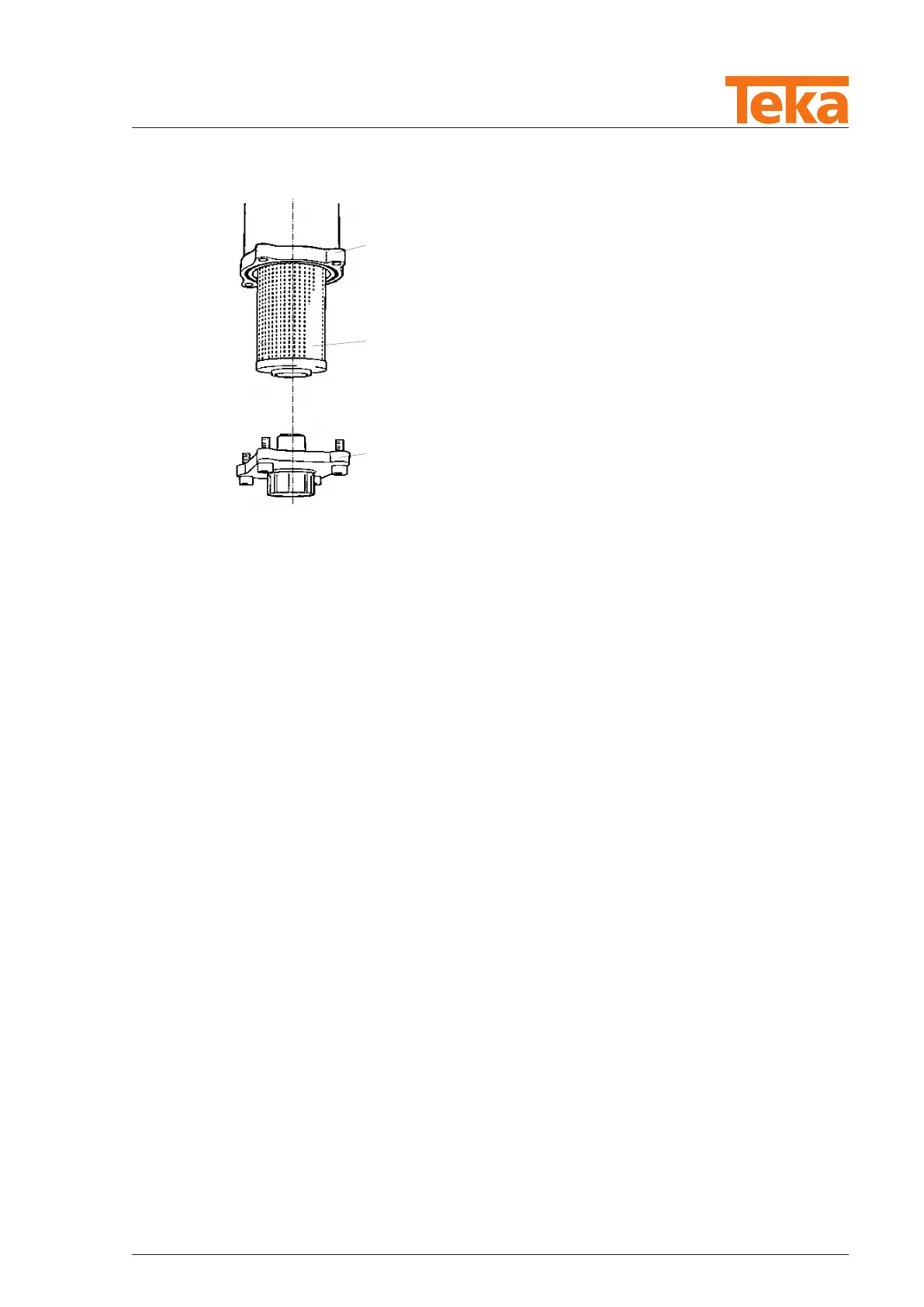

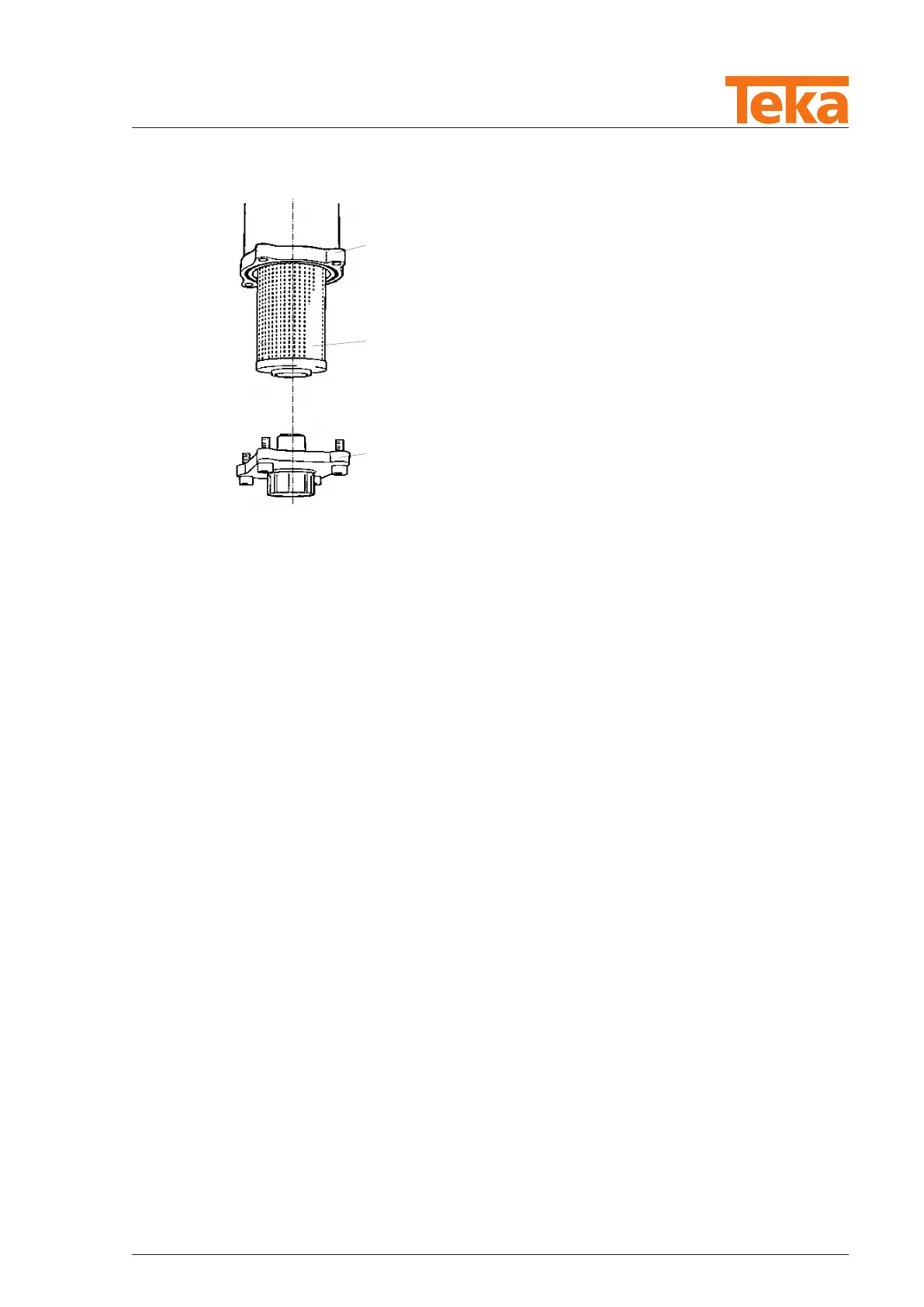

10.2.2.2 Filter replacement:

10

11

12

Fig. 58: Oilandlterreplacement3

10 Filter case

11 Filter with seals

12 Filter cover

1. Dismantle the suction line (8) between the lter case and lter (7) and the

hydraulic pump (6).

2. Unscrew the lter cover (12) under the lter case (10) and replace the lter cartridge and

seals (11). Replace damaged seal rings.

10.2.2.3 Adding oil:

Note the oil recommendation.

1. Reassemble all of the parts except for the oil dipstick (3).

2. Add oil. The maximum oil ll is indicated by the top marking on the oil dipstick.

3. Turn in the oil dipstick (3).

4. Briey place the mixer into operation and check the oil level.

If necessary, add oil. Only carry out the check with the machine at a standstill

(see 10.2.1 "Checking the transmission oil level").

10.2.2.4 Transmission ventilation:

1. The ventilation of the transmission is carried out during operation by means of a ventilation

lter (1).

This is located underneath the rotor (2).

If too much oil is added, oil can escape here.

2. The ventilation lter must be checked at regular intervals and after each oil change for

contamination and functional capability and cleaned or replaced if necessary.

3. Accessibility is via an opening in the rotor case, which is to be turned to the position via the

vent line.

Loading...

Loading...