HYDRAULICS

8E-21

SECTION 8E. FRONT AND REAR TRACTION MOTORS

TRACTION CIRCUIT

The traction circuit is a parallel/series circuit in which

the oil being delivered by the traction pump to the front

wheel motors is divided between the left and right

motors (parallel). This allows the wheel motors to

speed up or slow down independently to enable turn-

ing. The oil, once through the front wheel motors, goes

directly to the rear wheel motors (series). This results in

improved traction, as both the front and rear wheel on

one side must break traction in order for the drive to

stop moving the tractor, as oil will follow the path of

least resistance.

The rear wheel motors are equipped with directional

check valves that close when moving forward and open

for reverse. The result is four-wheel drive when travel-

ing forward and an automatic shift to two-wheel drive

when in reverse.

The traction circuit on four-wheel drive units is addition-

ally equipped with a hot oil shuttle. The hot oil shuttle

drains off hot oil from the closed loop traction circuit

back to the reservoir. The drained-off oil is replenished

with cooler oil in the circuit by the charge pump in the

traction pump. The hot oil shuttle opens when traveling

forward and closes when in reverse direction.

On two-wheel drive models the traction circuit can be

equipped with an optional differential lock valve. The

differential lock valve is essentially a flow divider

installed between the traction pump and the front wheel

motors. When activated, the flow divider equally splits

the amount of oil flow from the traction pump to the

front wheel motors so that they turn at the same speed.

The flow divider hinders left and right turns when acti-

vated.

IMPORTANT: In general, when a component failure

occurs in the traction circuit, such as a traction pump or

wheel motor, the closed loop circuit of the traction

pump may become contaminated with metal particles

which could damage expensive new replacement

components. In a situation where contamination has

occurred, the closed loop circuit must be pressure

filtered in both the forward and reverse directions for at

least 20 minutes using the Portable In-Line Filter

#JAC5097. Failure to filter the system will contaminate

and destroy new replacement components.

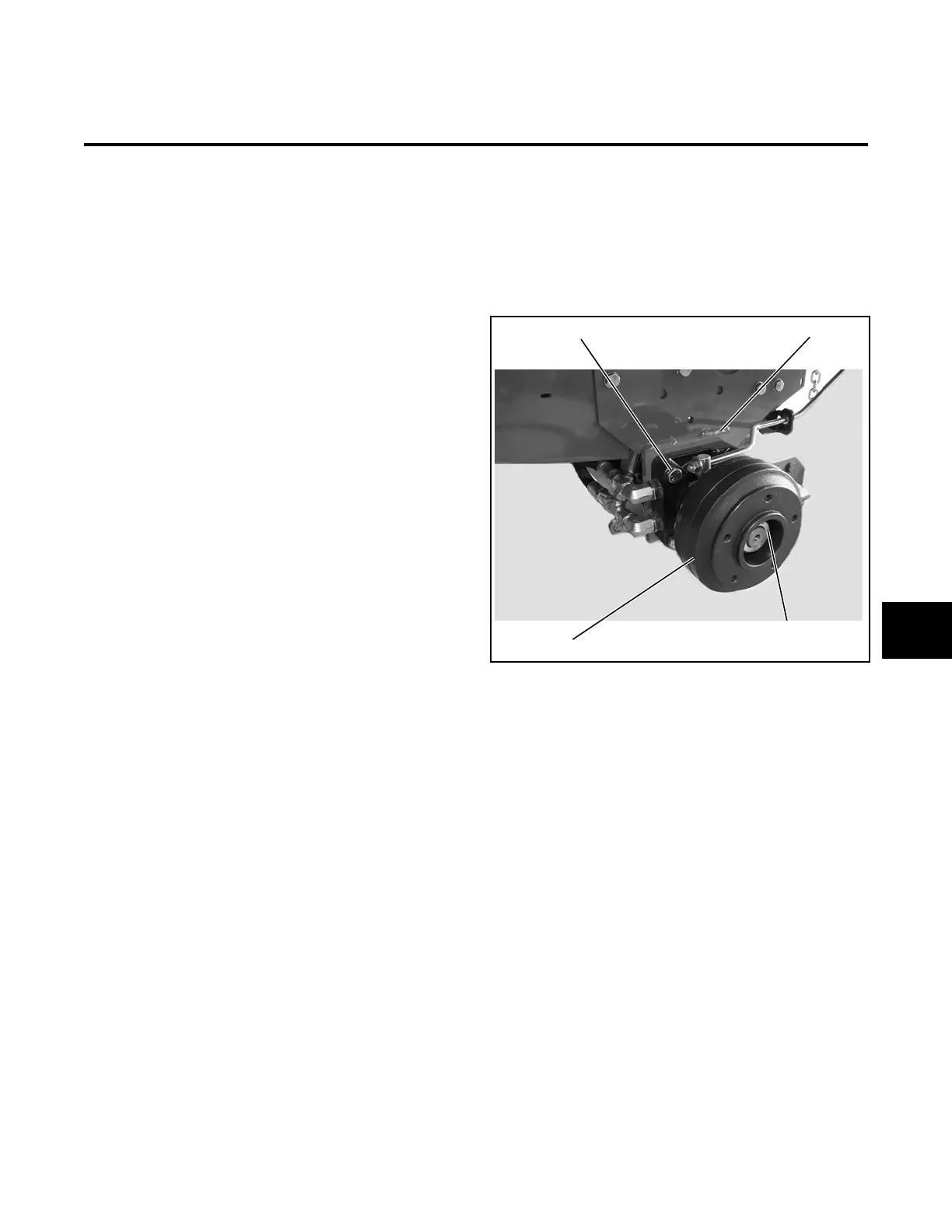

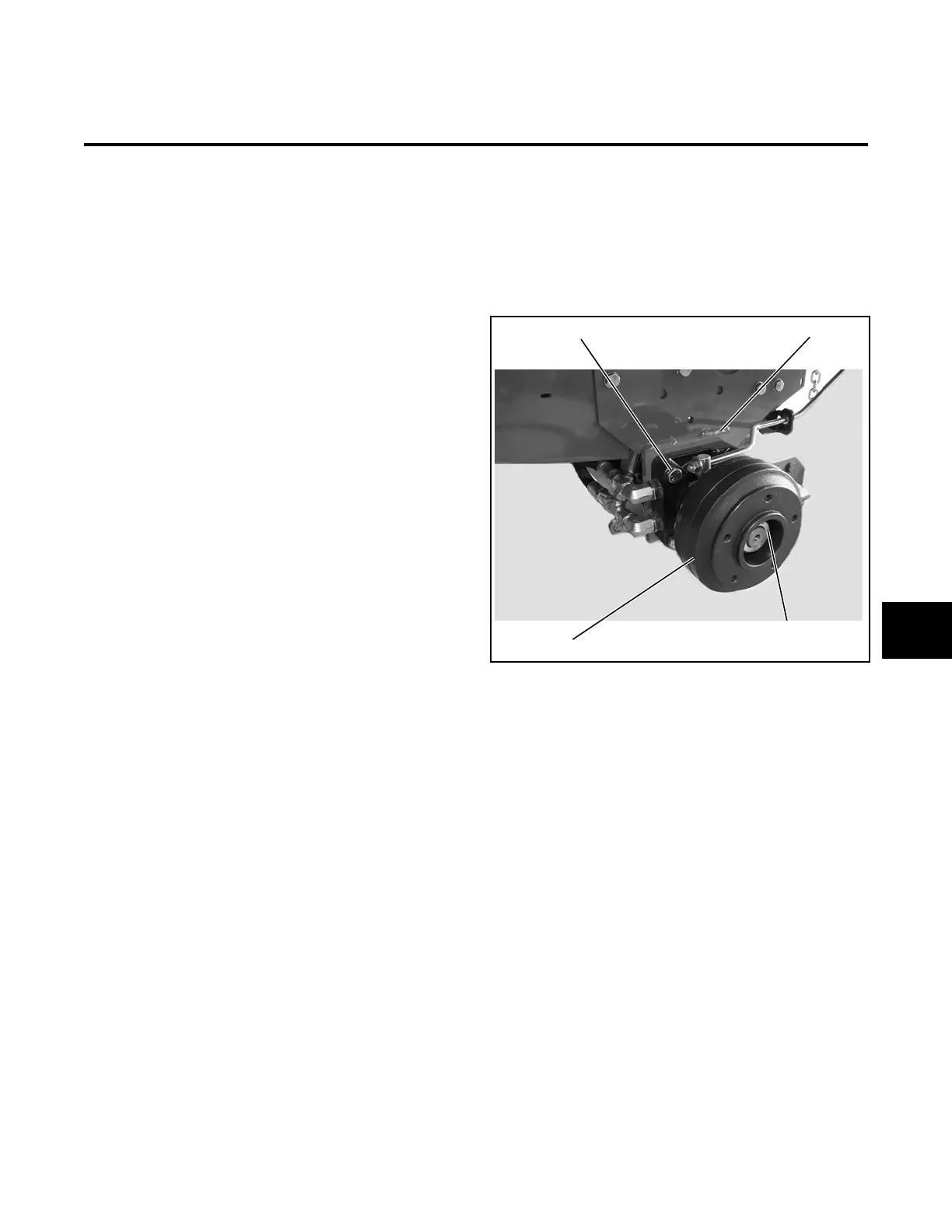

FRONT TRACTION MOTOR

The traction pedal and traction pump control the front

traction motors. The motor is mounted to the tractor

frame inside the front wheel mounting. The brake drum

is attached to the motor shaft end and serves as the

wheel mounting.

Figure 8E-1. Brake Drum and Traction Motor

Mounting

Removal

1. Shut off engine and remove ignition key.

2. Using jack stands, lift and support the front axle.

3. Remove the wheel and tire assembly.

4. Remove the brake drum nut, brake drum, brake

shoes, and backing plate (Section 5).

5. Thoroughly clean the motor, especially the area

surrounding the hydraulic fittings.

6. Tag and disconnect the hydraulic hoses from the

motor. Immediately plug the hoses and motor to

prevent contamination of the hydraulic system.

7. While supporting the motor, remove the four

mounting bolts.

8. Remove the motor from the tractor frame.

Brake Drum Nut

Tractor FrameMounting Bolts

Brake DrumBrake Drum

8E

Loading...

Loading...