PREVENTIVE MAINTENANCE

11B-6

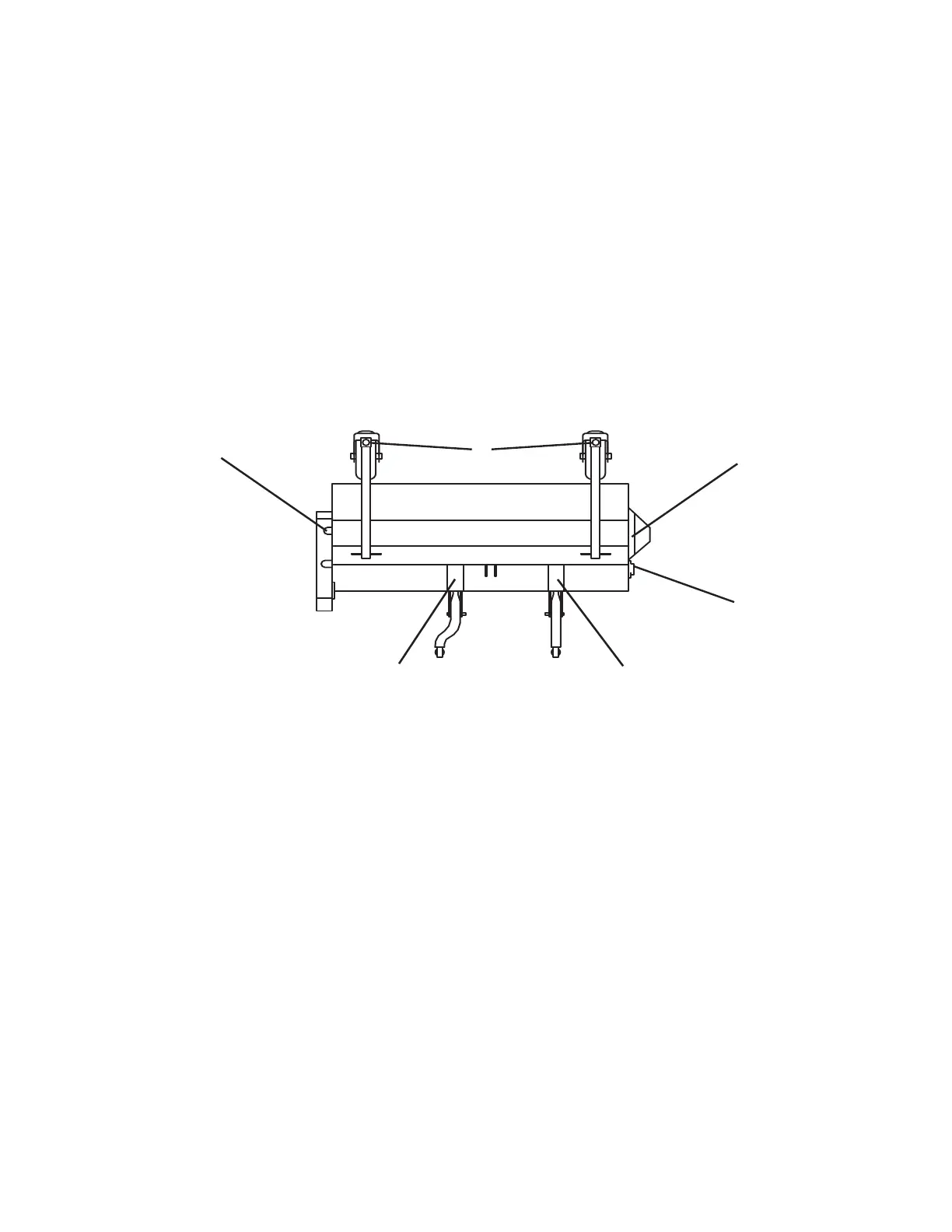

FLAIL MOWER

Lubricate grease fittings every 50 hours of operation or

more frequently when operating in extremely dusty con-

ditions.

1. Always clean grease fittings before and after libri-

cating.

2. Lubricate with grease that meets or exceeds NLGI

Grade 2 specifications.

3. Apply grease with a manual grease un and fill

slowly until grease begins to seep out or pressure

is felt. Never use compressed air guns.

Flail Mowers

(1) Caster Spindles

(2) Rotor Bearings

(3) Roller Bearings

(4) Push Arm Pivots

(5) Motor Spline Adaptor

4. Remove motor and lubricate motor adapter spline

(5) using NLGI Grade 2, every 100 hours of opera-

tion

5. For smooth operation of other pivot and friction

points, apply several drops of SAE 30 wt. oil every

50 hours or as required.

Figure 11B-3. Flail Mower Lubrication Points

3

Both

Sides

4

4

2

2

1

Loading...

Loading...