HYDRAULICS

8D-11

SECTION 8D. HYDROSTATIC TRACTION PUMP

GENERAL

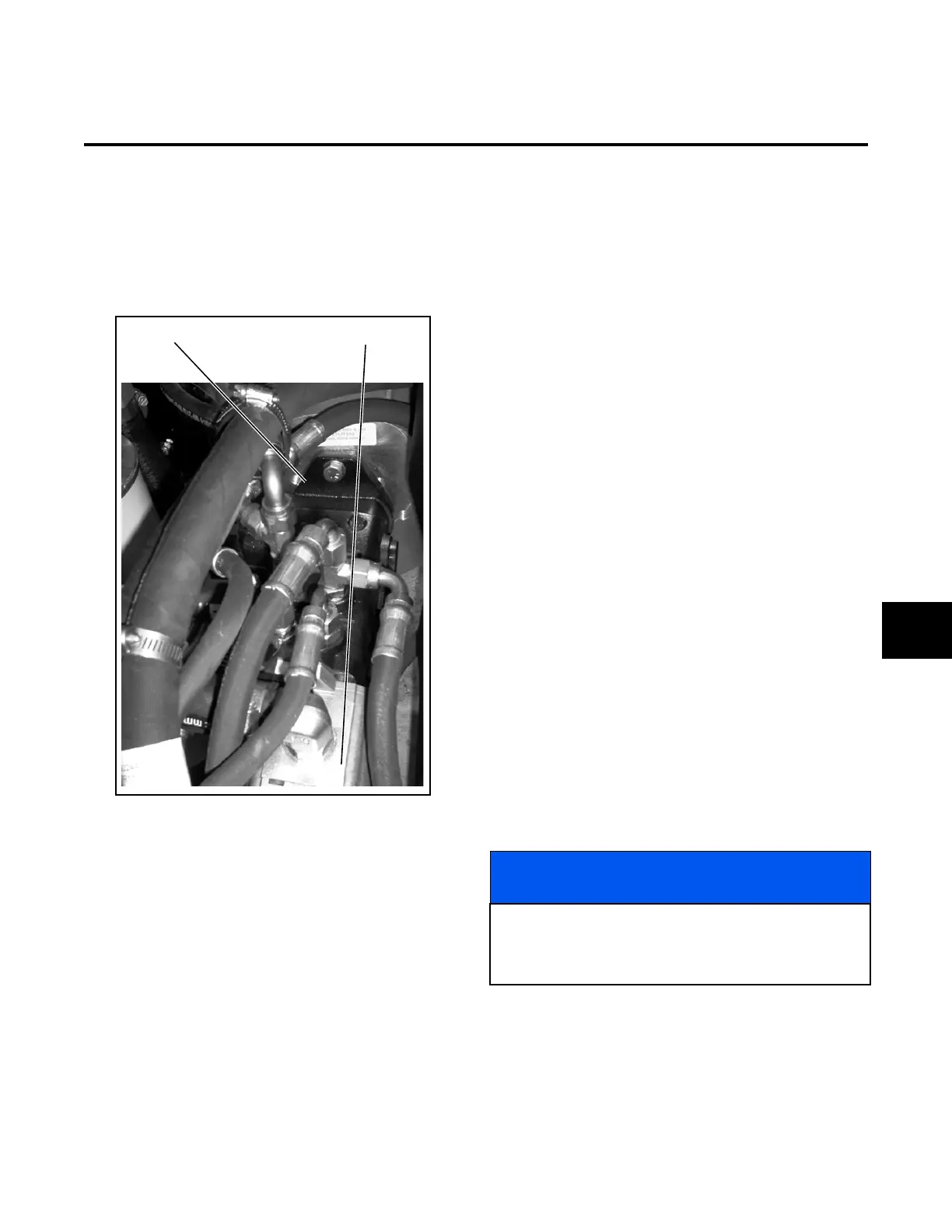

The hydrostatic traction pump (Figure 8D-1) is

mounted underneath the seat pan and in front of the

engine. The pump is driven by the engine through a

spline shaft direct coupling. The traction pump is bolted

to a bell housing.

Figure 8D-1. Traction Pump/Implement Pump

The hydrostatic traction pump consists of two pumps

(Figure 8D-2). The 0.425 cu. in. gerotor pump supplies

oil to the steering, lift, and charge circuits. The charge

circuit charges the traction pump and circuit with oil.

The second, a 1.35 cu. in. piston pump, supplies oil to

the traction circuit.

A set of eight pistons and barrel assembly produce

pump suction and pressure. The pistons have shoes

that ride against a swiveling swashblock. By swiveling

the swashblock, the piston stroke is extended on one

side of the barrel assembly and shortened on the other

side. The extended piston stroke produces hydraulic

pressure, which is directed to one side of the wheel

traction motors, turning the motors and attached

wheels. Oil passes through the motor and returns to

the traction pump.

When the swashblock is swiveled in the opposite direc-

tion, oil flows to the opposite side of the traction motors

turning the motor and attached wheels.

The direction of the swashblock swivel is controlled by

the traction pedal and pump control arm.

A supercharge pump is mounted between the rotating

group and rear valve plate assembly. The pump draws

fluid from the hydraulic tank and supplies hydraulic

pressure to the steering unit and the traction circuits

through the cross port relief valves.

Repair of the traction pump is limited to replacement of

the various pump group service kits. These kits are

illustrated and defined by part numbers in the parts

section of the Parts & Maintenance Manual.

Before disassembling the traction pump (Figure 8D-3),

perform the hydraulic tests in Section 8M to verify that

the pump is at fault.

Disassemble only what is necessary to facilitate

needed repairs. Use the following procedure taking

note of special instructions. If possible, do not remove

locator pins. Discard and replace all o-rings, backup

rings, and gaskets.

Disassembly should be in an area free of dust, dirt and

away from grinding and welding areas. Keep parts in a

bath of clean hydraulic fluid.

Traction Pump

Implement Pump

NOTICE

The system must be high pressure filtered after any

repairs to the traction pump or motor. A suitable high

pressure filter such as the Jacobsen 5097 is recom-

mended.

8D

Loading...

Loading...