ENGINE

3D-17

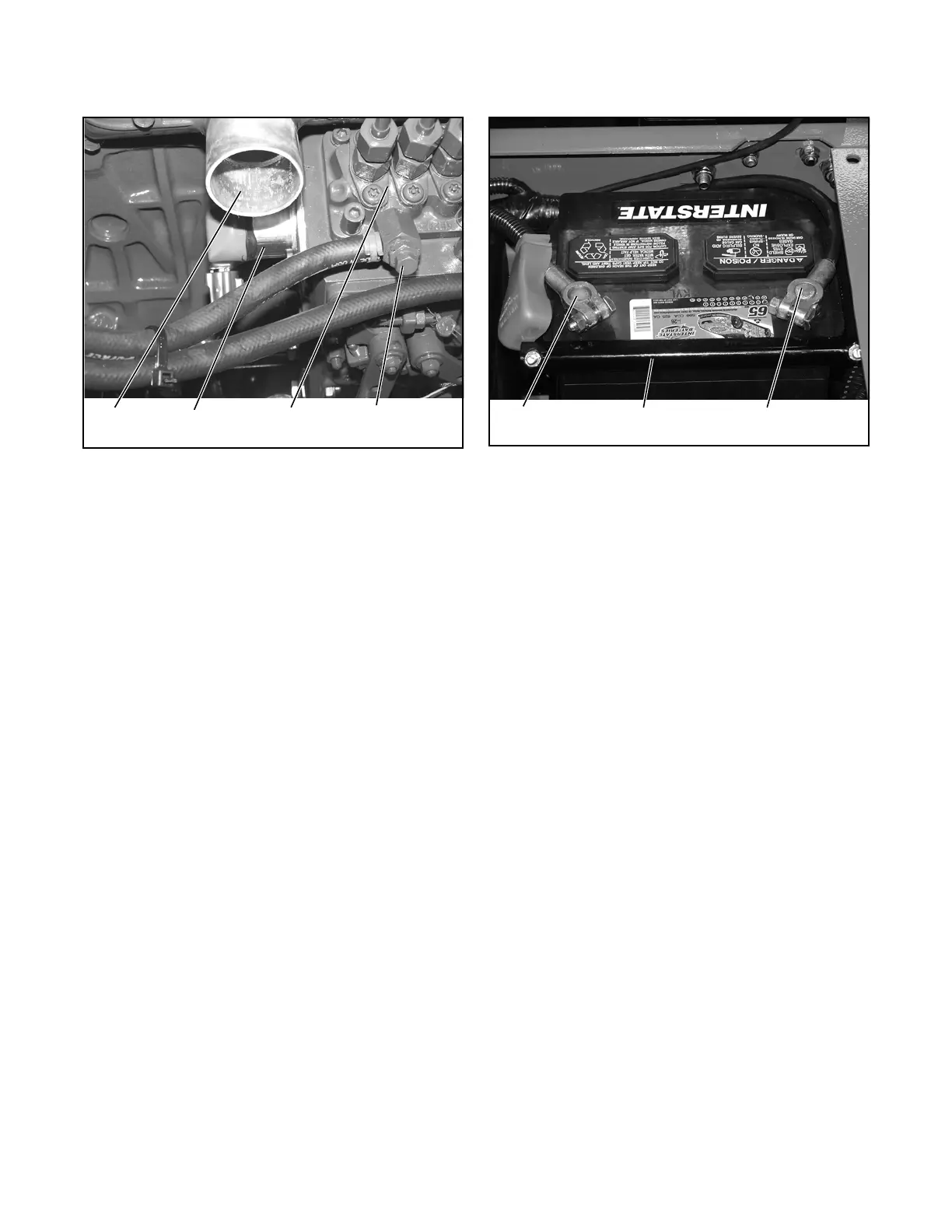

Figure 3D-16. Injection Pump Air Vent

18.Operate the primer button on top of the fuel/water

separator to fill the fuel lines with fuel.

19.Allow fuel to flow from the injection pump vent until

air bubbles no longer appear. Tighten the air vent

plug (Figure 3D-16).

20.Inspect the fuel filter, hoses, clamps, and pipes for

leaks. Repair as necessary.

ENGINE REMOVAL

The engine is mounted behind the driver’s seat and

drives the traction pump using the drive coupler. Some

components can be serviced or removed using proce-

dures previously described in this section.

1. Shut down the engine and remove the ignition

key. Allow the engine to cool completely before

attempting to service the engine.

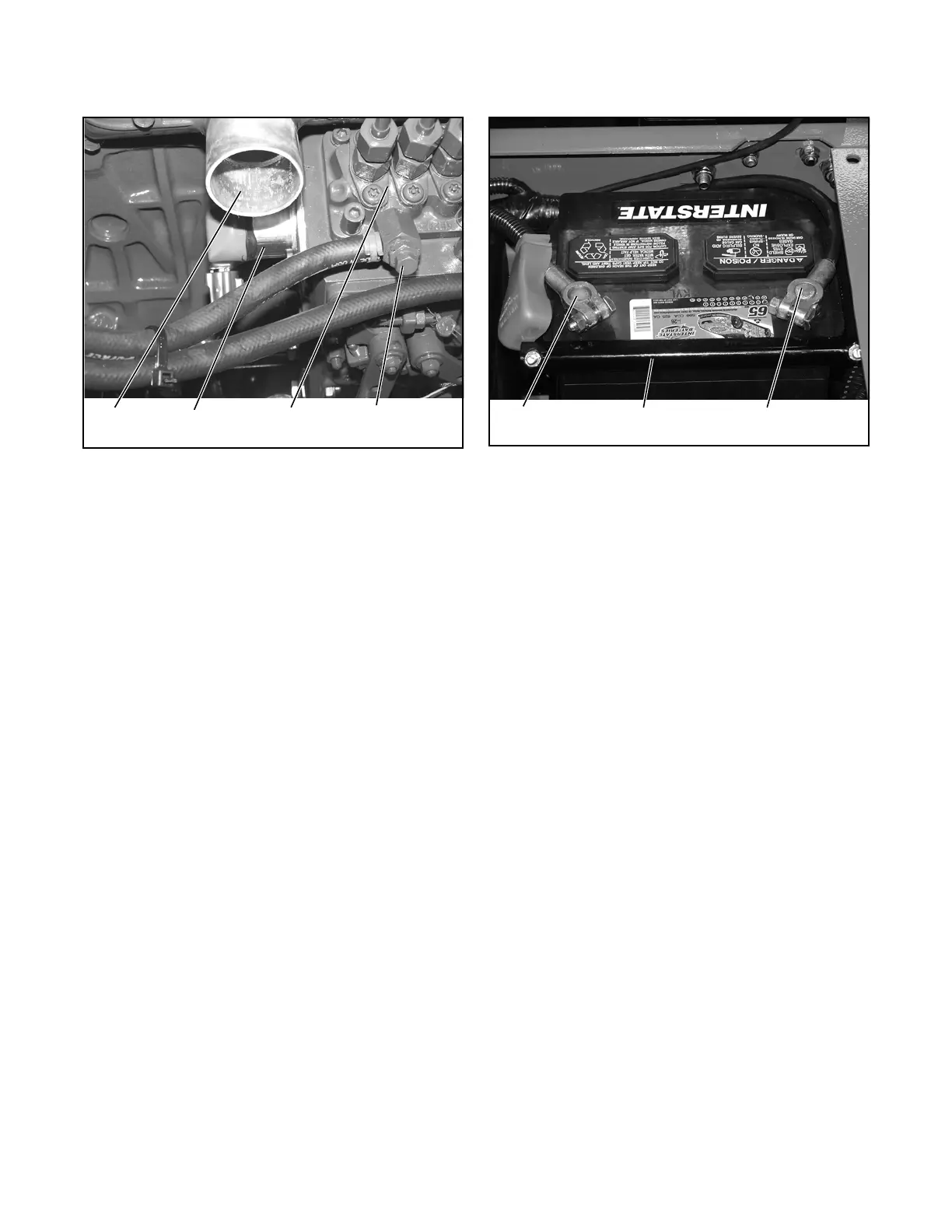

2. Disconnect the negative battery clamp first, then

remove the positive clamp. Remove the battery

hold down clamp and battery (Figure 3D-17).

Figure 3D-17. Battery Cables and Clamp

3. Using suitable containers, drain the radiator,

engine block, engine oil and hydraulic oil.

4. Remove the upper and lower radiator hoses.

5. Tag and disconnect the hydraulic inlet and outlet

hoses from the oil cooler. Immediately plug the

hoses and cooler ports to prevent contamination

of the hydraulic system.

6. Remove the air cleaner assembly hoses.

7. Remove the radiator/oil cooler assembly

8. Drain the fuel tank.

9. Disconnect the fuel outlet hose from the fuel tank

to the inline filter. Immediately plug the hose to

prevent contamination.

10.Disconnect the throttle cable from the injection

pump and the throttle cable housing from the

clamp (Figure 3D-18).

Fresh Air

Intake

Fuel

Solenoid

Injection

Pump

Air Vent

Plug

Positive

Cable

Battery

Clamp

Negative

Cable

Loading...

Loading...