HYDRAULICS

8M-63

Conclusion

• If gauge reading is within specification at both high

and low idle positions, pump and relief valve are

okay.

• If pressure gauge reading is within specification at

high idle and out of specification at low idle, perform

flow test on implement pump.

• If pressure gauge reading is out of specification and

pressure is the same at both high and low idle,

repair or replace deck relief valve.

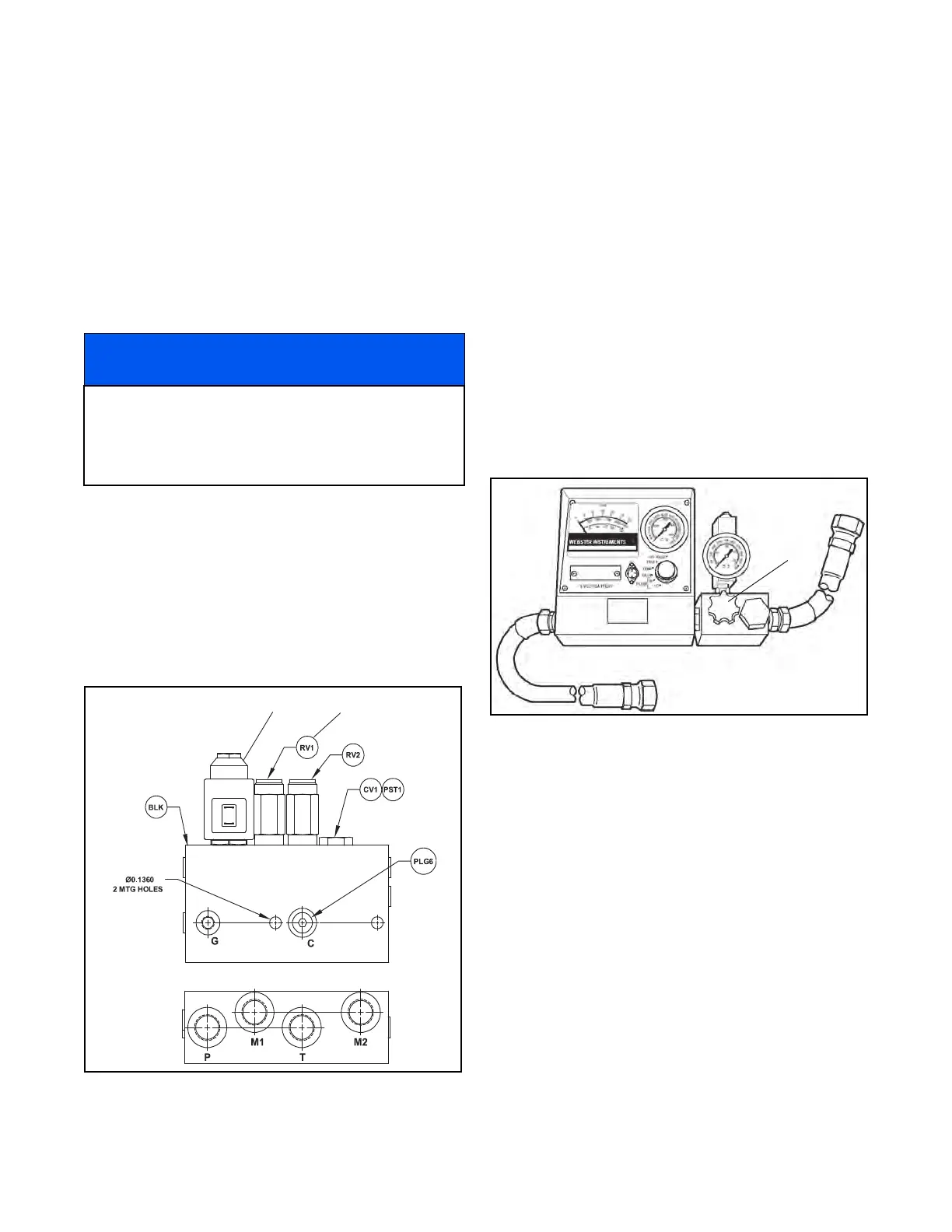

Deck Relief Valve

1. Shut off the engine.

2. Drain hydraulic fluid from the tank.

3. Lift seat platform.

4. Remove solenoid coil from cartridge on the deck

valve (Figure 8M-12).

Figure 8M-12. Deck Relief Valve

5. Using a socket, remove the relief valve (RV1) from

the deck valve. Replace seals or relief valve as

required.

6. Install relief valve and solenoid coil.

7. Replace hydraulic fluid in the tank.

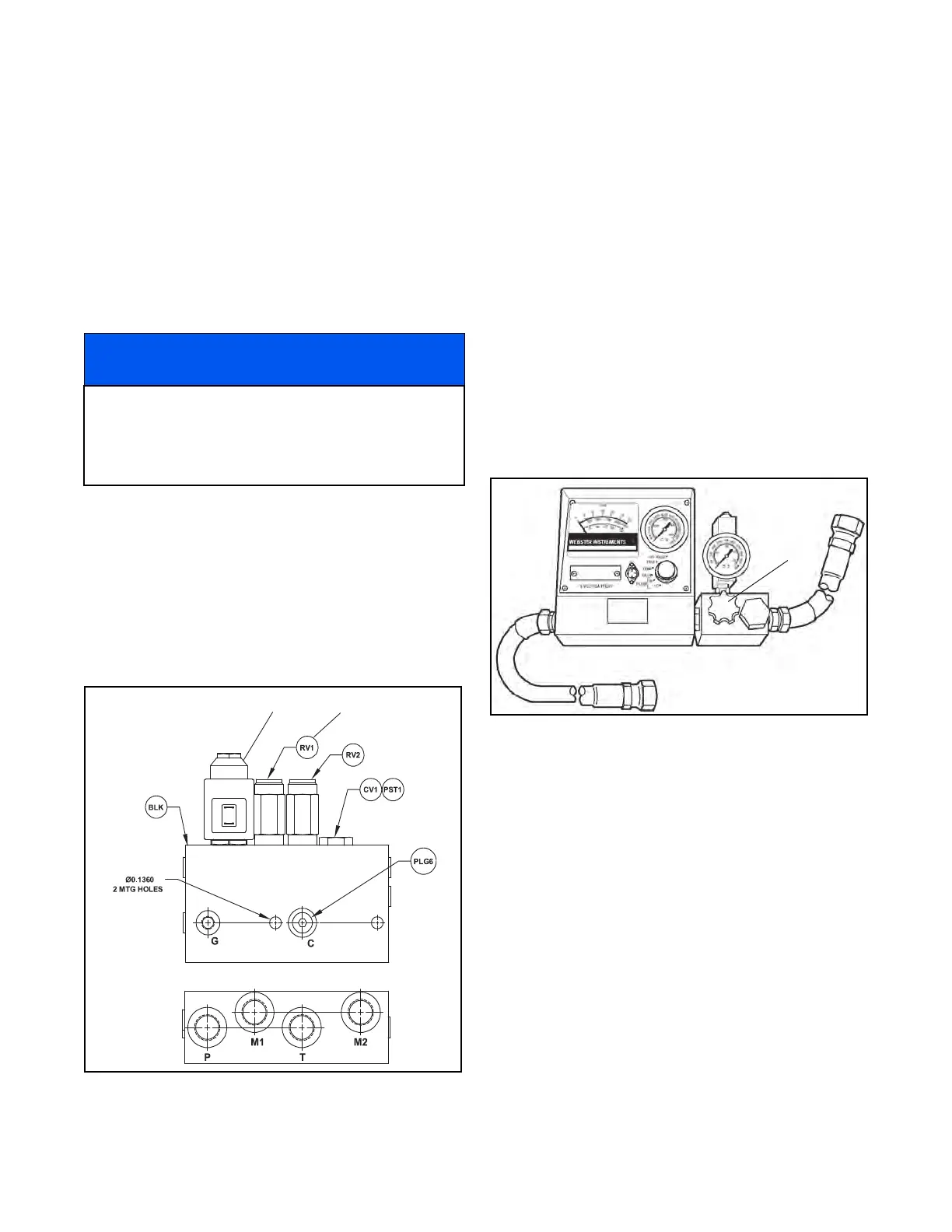

FLOW TESTS

Follow the directions for each test carefully. Before per-

forming any test, be sure oil is at operating temperature

120 – 150°F (49 – 65°C) and the engine is at full high

idle speed of 3150 rpm.

Read and understand the flow meter directions and

instructions before attempting to test the hydraulic sys-

tem.

Set up flow meter to perform a series test. (Figure 8M-

13).

Figure 8M-13. Flow Meter

Charge Pump Test

The traction pump charge pump supplies oil flow to the

steering, deck lift, and traction circuit for charging the

traction pump closed loop circuit.

1. Shut off the engine and remove the ignition key.

2. Connect the flow meter “IN” port to the charge

pump outlet fitting on the traction pump.

(Figure 8M-14).

3. Connect the flow meter “OUT” port to the charge

pump outlet hose (Figure 8M-14).

4. Open the tester load valve, set the parking brake,

start the engine, and advance the engine speed to

high idle speed.

NOTICE

The deck valve solenoid cartridge can also affect the

pressure of the deck circuit if the o-rings are leaking

on the cartridge. A flow test on the implement pump

will determine whether the problem is in the pump or

the deck valve.

Solenoid Coil Relief Valve

Loading...

Loading...