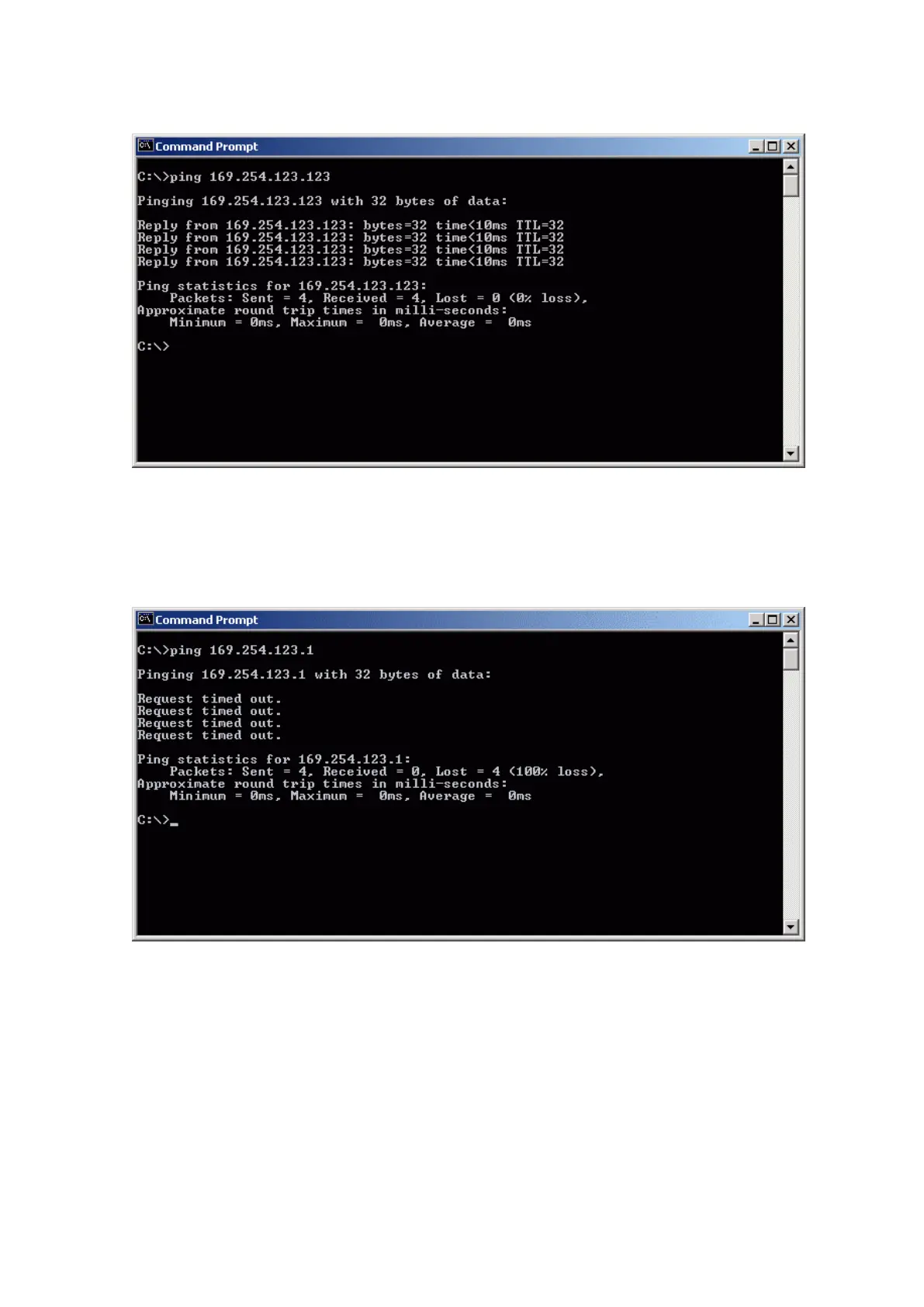

Figure 127 Ping OK

15.3.1

Troubleshooting connection

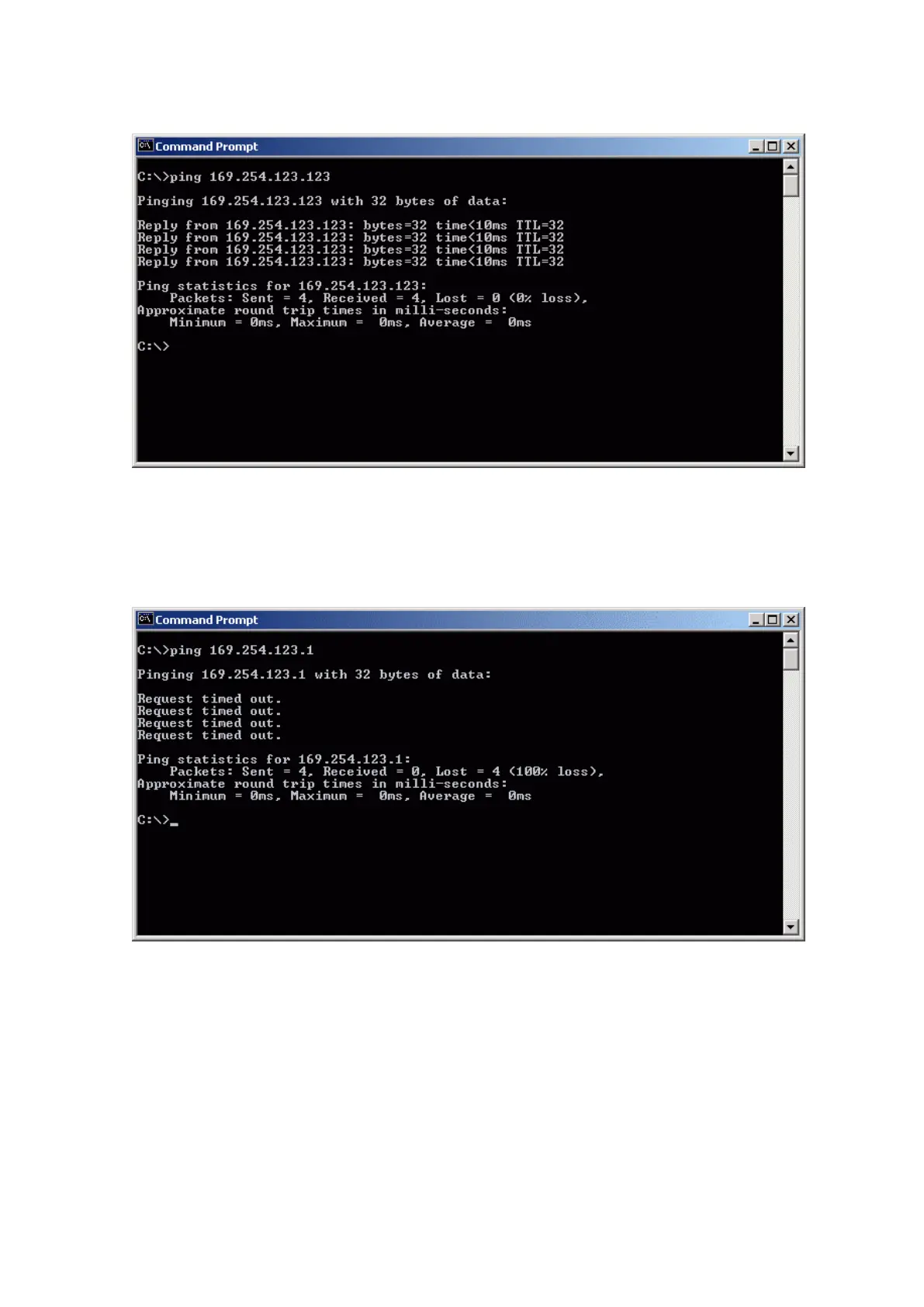

Figure 128 Ping error message

If you get a ping error message, check your connections.

Open the DTR cover and front panel and check the diagnostic LEDs of the Ethernet

connector, see Connecting Ethernet cable (page 229).

Chapter 15 – Ethernet connection specification

233

Loading...

Loading...