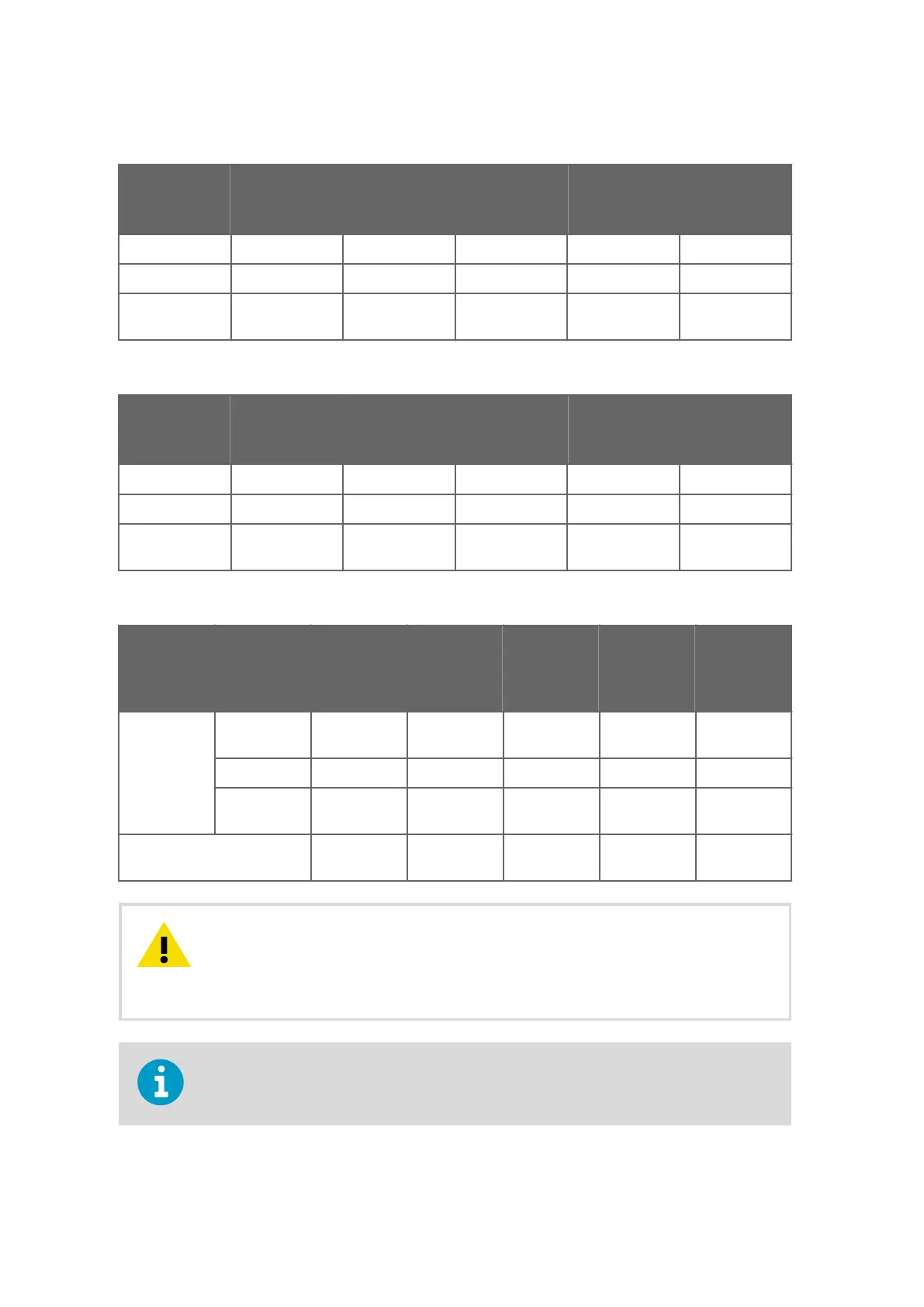

Table 3 Wash medium parameters for integral wash nozzles in PR‑23‑AP

/GP

Minimum

abo

ve process

pressure

Maximum

above process

pressure

Wash time Recovery Interval

Steam (SN) 2 bar (30 psi) 4 bar (60 psi) 3 s 20 … 30 s 20 … 30 min

Water (WN) 2 bar (30 psi) 4 bar (60 psi) 3 s 20 … 30 s 20 … 30 min

High pressure

w

ater (WP)

15 bar (220 psi) 40 bar (600 psi) 10 s 20 … 30 s 10 … 20 min

Table 4 Wash medium parameters for flo

w cell wash nozzle AFC

Minimum

abo

ve process

pressure

Maximum

above process

pressure

Wash time Recovery Interval

Steam (SN) 3 bar (45 psi) 6 bar (90 psi) 3 … 5 s 20 … 30 s 20 … 30 min

Water (WN) 3 bar (45 psi) 6 bar (90 psi) 10 … 15 s 20 … 30 s 10 … 20 min

High pressure

w

ater (WP)

25 bar (350 psi) 35 bar (500 psi) 10 … 15 s 20 … 30 s 10 … 20 min

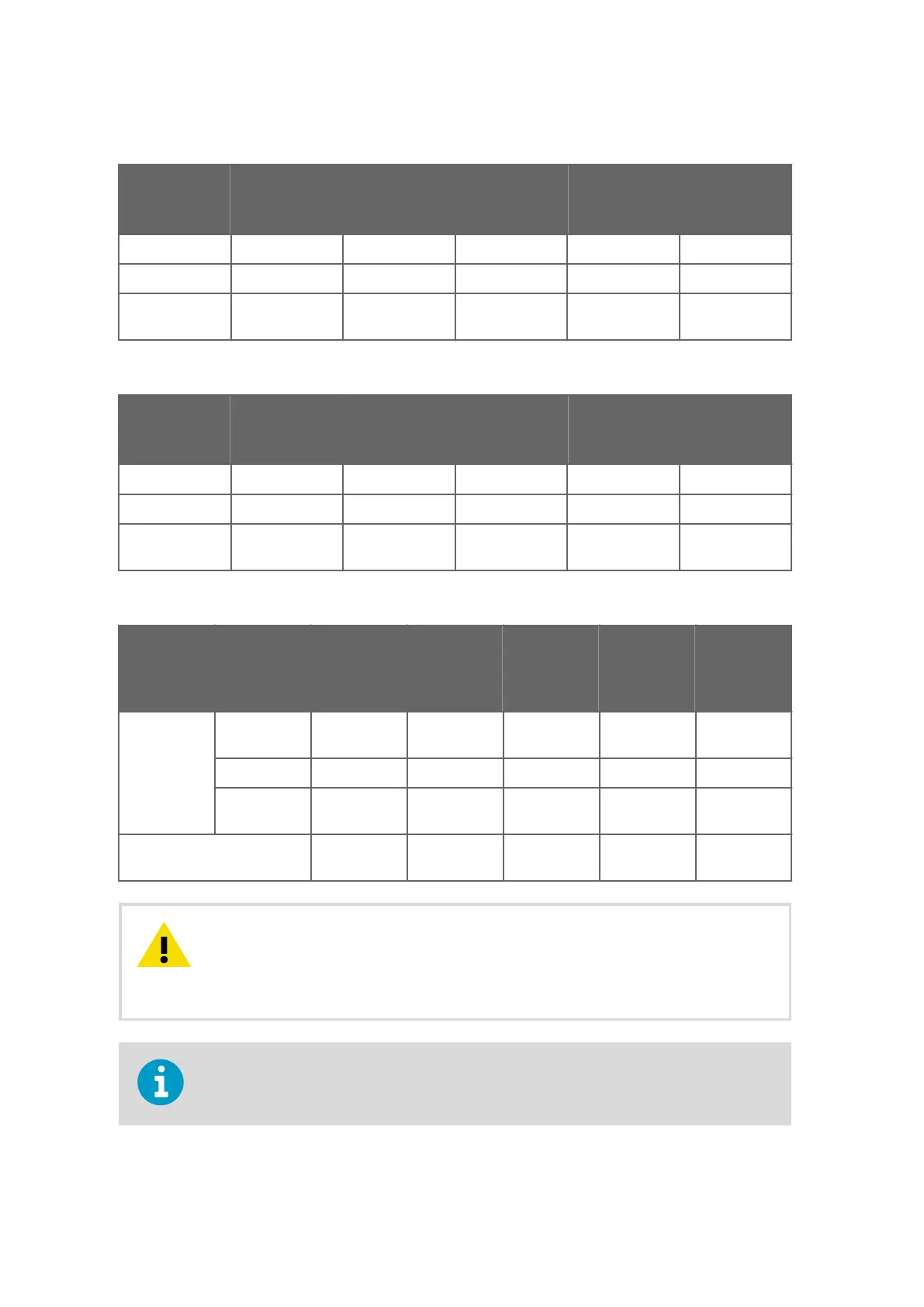

Table 5 Wash medium parameters for Safe‑Driv

e isolation valve nozzle SDI

CONC %

v

alue

Minimum

above

process

pressure

Maximum

above

process

pressure

Wash time Recovery Interval

Steam (SN) 10 … 30 % 2 bar (30 psi) 4 bar (60 psi) 2 … 3 s 20 s 120 … 360 mi

n

30 … 60 % 3 bar (45 psi) 6 bar (90 psi) 3 s 20 s 20 … 60 min

60 … 90 % 4 bar (60 psi) 8 bar

(120 psi)

3 … 5 s 20 s 15 … 25 min

High pressure water (WP) 25 bar

(3

50 psi)

30 bar

(435 psi)

10 … 15 s 20 s 5 … 20 min

In steam wash, do not exceed the recommended wash times, because some

pr

ocess media can burn to the prism surface if steamed for longer time. In case of

coating, shorten the wash interval.

For the Automatic wash cut parameter, see Setting prism wash parameters (page 82).

CAUTION!

In water wash, water temperature should be above the process temperature.

PR-23 Series User Guide

IM-EN-PR23-E

38

Loading...

Loading...