The value of the bias parameter f00 is added to the concentration value:

NEW CONC = OLD CONC + f00.

7.5 Configuring prism wash

In some applications the process flow does not keep the prism clean because of sticky

process medium or low flow velocity. In these applications the prism can be automatically

cleaned by installing a wash system.

The prism wash settings for sensors A and B are independent of each other. The wash

system is active if a relay has been configured to be a wash relay, see Configuring relays

(page 66), and the wash time is not zero. An automatic wash function can be configured so

that both sensors have dierent parameters.

More information

‣

Prism wash systems (page 39)

7.5.1

Wash cycle

Figure 42 (page 79) shows the wash logic as a flow diagram. The automatic prism wash

cycle described below consists of three phases: precondition, wash and recovery. The

optional preconditioning function is used to, for example, blow out the condensate before

washing. After the preconditioning there is a one-second pause to avoid having both

precondition and wash relays active at the same time.

The wash cycle is initiated when the wash interval has elapsed. The wash can also be started

by closing an external switch, see Configuring input switches (page 68), or manually from

the user interface at the Sensor status display, see Testing prism wash (page 51). The order

of priority for these wash triggers is as follows:

1. Manual wash

2. Remote wash request

3. Wash interval timer

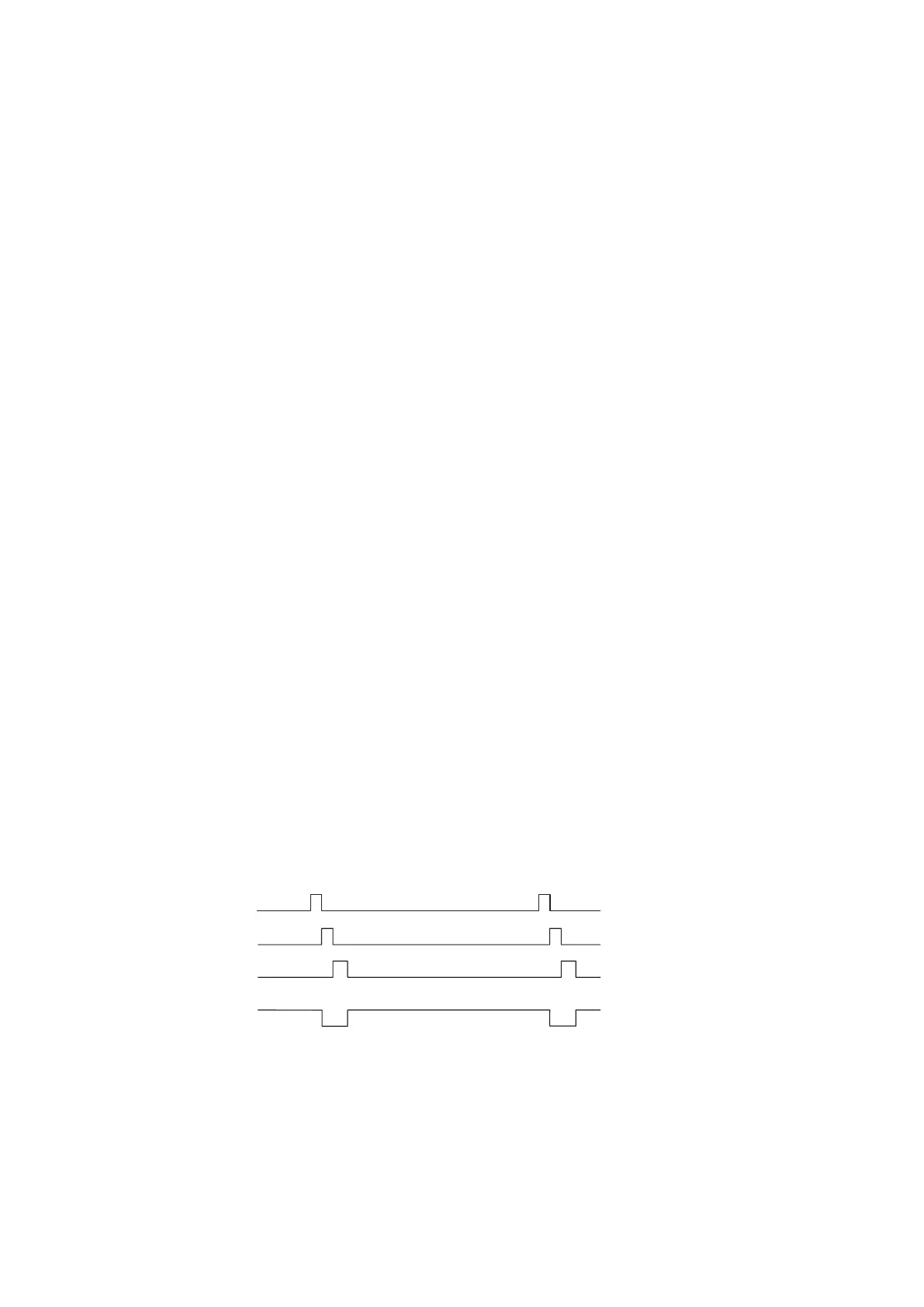

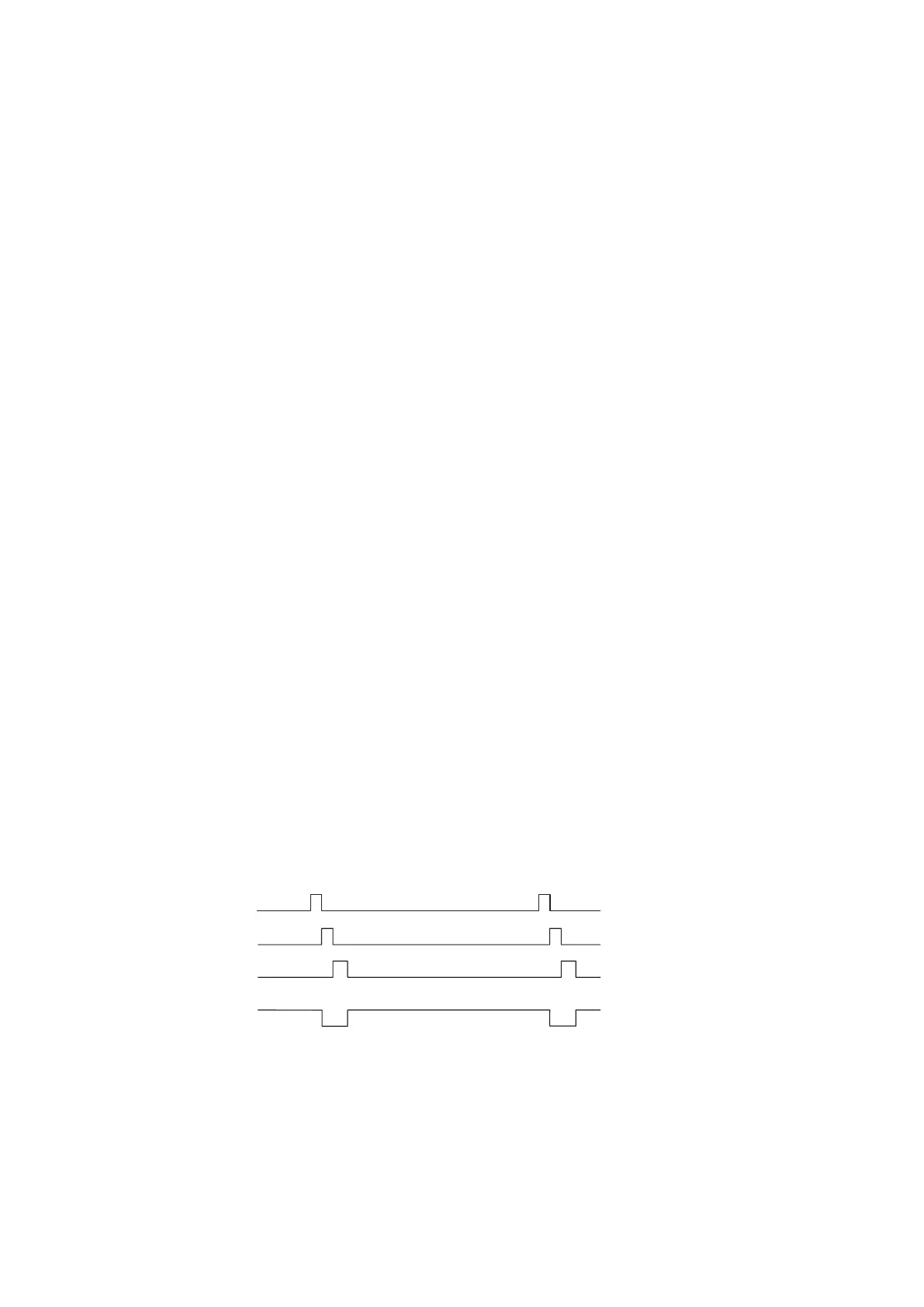

WASH

RECOVERY

INTERVAL

PRECOND.

Figure 41 Automatic prism wash cycle

Chapter 7 – Configuration and calibration

77

Loading...

Loading...