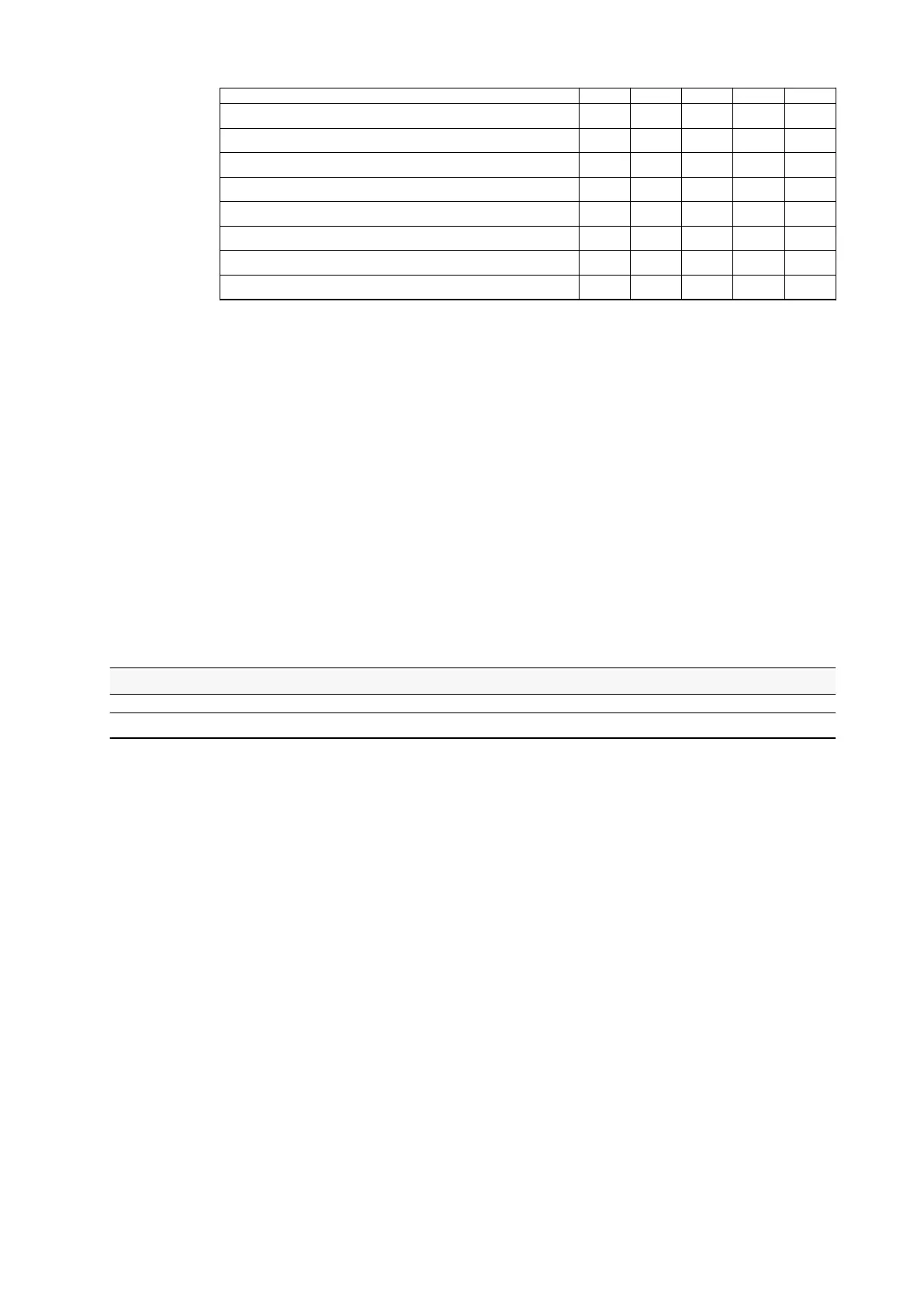

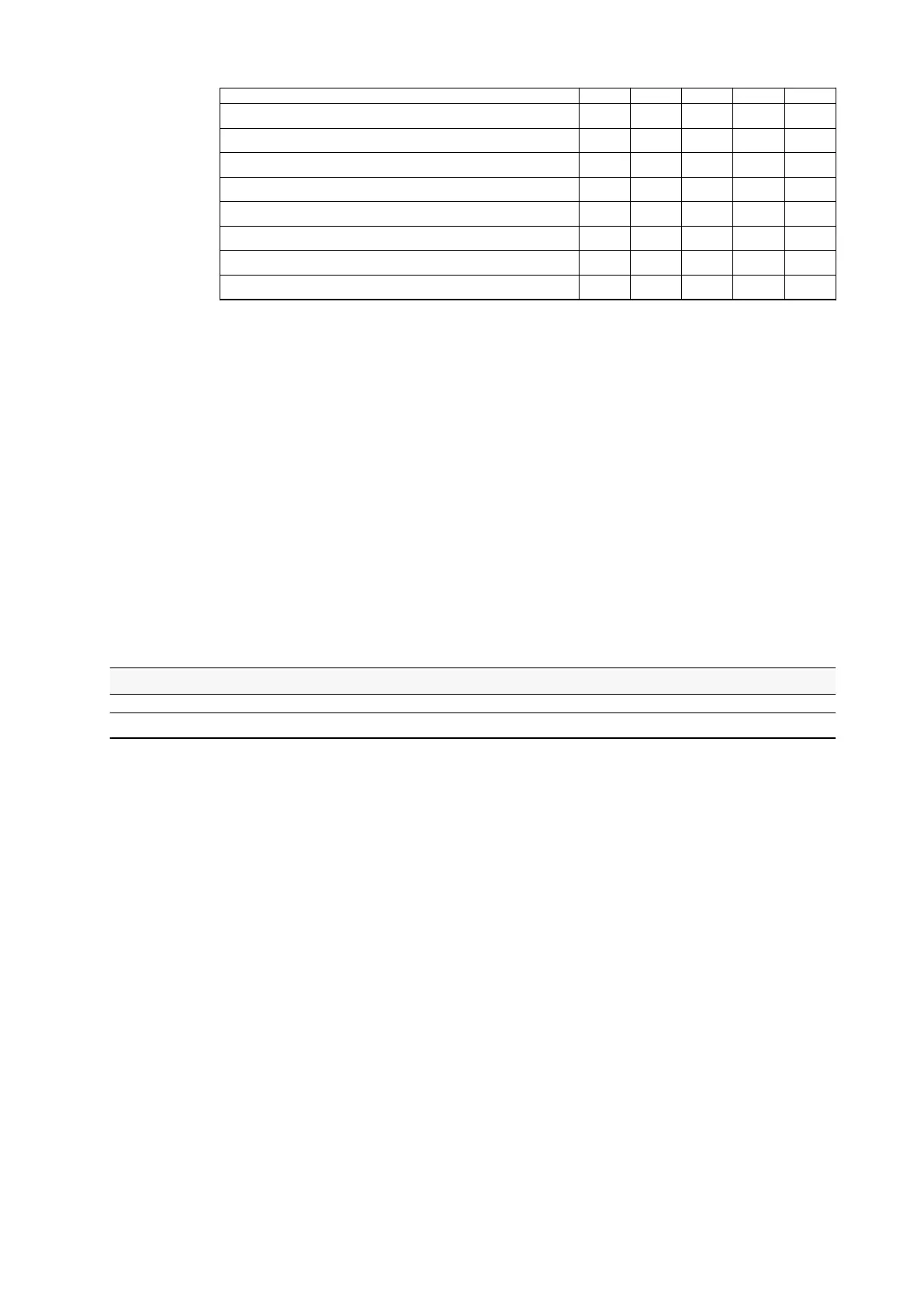

Maintenance check point 10 h 50 h 600 h 1200 h 2400 h

Change the oil in the transmission system. ●

Change the transmission breather. ●

Clean the suction strainer. ●

Bleed the brake system. ●

Clean the cooling system. ●

Change the cap of the coolant expansion tank. ●

Check the cab mounting. ●

Maintain the air conditioning. ●

1)

NOTE: In extremely dusty conditions or when using first generation Biodiesel fuel with dilution

over 7%, change the oil and filters every 250 hours. With second generation Biodiesel fuel the

service interval is normal (600 hours).

2)

NOTE: In extremely dusty conditions the cab ventilation air filter must be cleaned frequently.

3)

IMPORTANT: The front loader frame bolt tightness must be checked every 50 hours if the front

loader is used continuously with heavy loads.

4)

NOTE: The software must be updated and the tractor calibrated after 600 operating hours. After

the first update and calibration, do them at 1200 hours and after this every 1200 hours.

5)

NOTE: The engine valves must be adjusted after 600 operating hours. After the first adjustment,

adjust the valves at 2400 hours and after this every 2400 hours.

6)

NOTE: When using first generation Biodiesel fuel with dilution over 7%, change the fuel filter

and prefilter every 500 hours. With second generation Biodiesel fuel the service interval is 1000

hours.

7)

NOTE: In extremely dusty or cold conditions, change the fuel filter and prefilter every 600 hours.

8)

NOTE: In extremely dusty conditions the engine air filters must be changed more frequently.

9)

NOTE: In extremely dusty conditions the selective catalytic reduction system breather must be

changed more frequently.

4.7.2 Daily maintenance

4.7.2.1 Checking the engine oil level

Check the engine oil level periodically.

The engine oil level must be checked when the oil has cooled off and has had

time to run down to the bottom of the oil sump.

4. Maintenance

- 345 -

Loading...

Loading...