Watlow F4T • 99 • Chapter 5 Function Reference

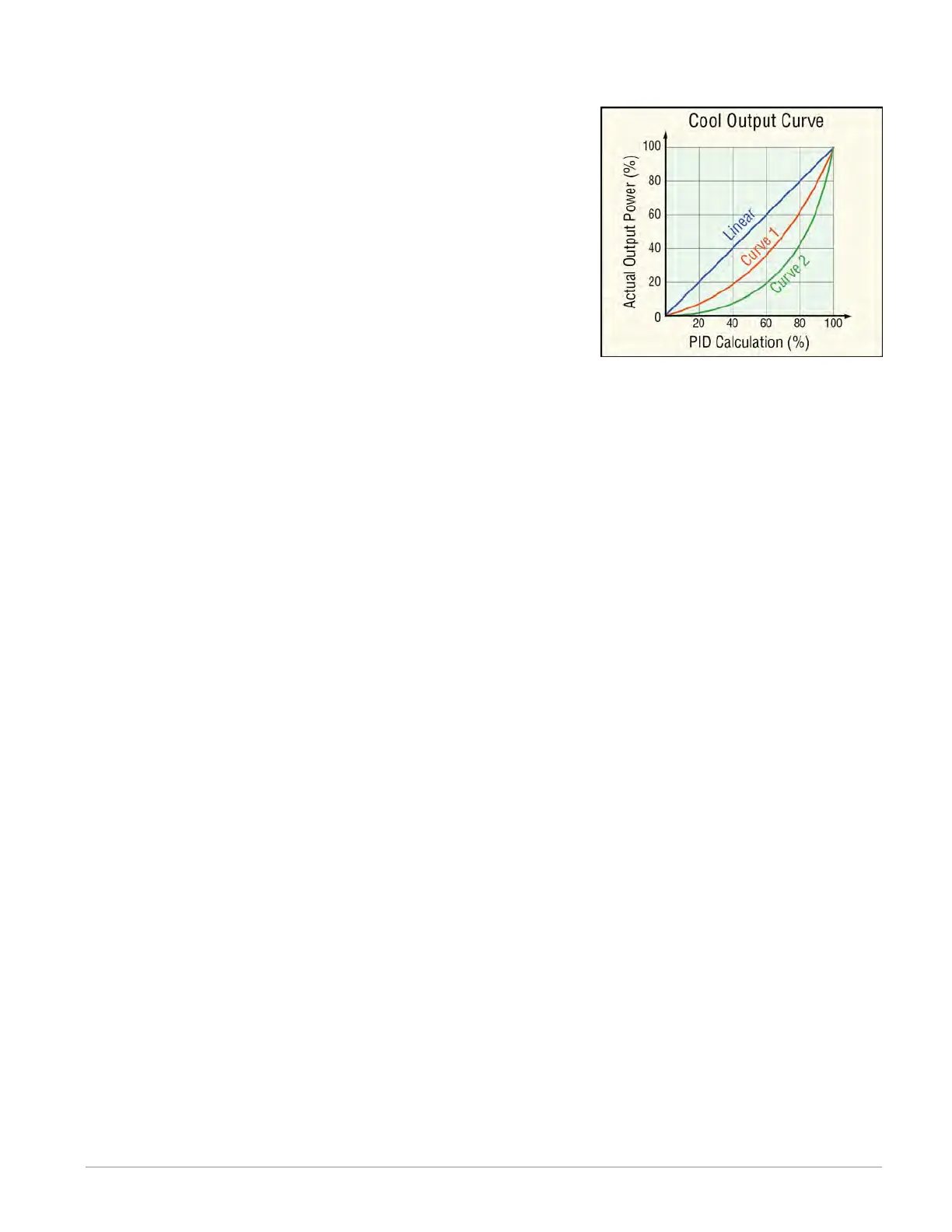

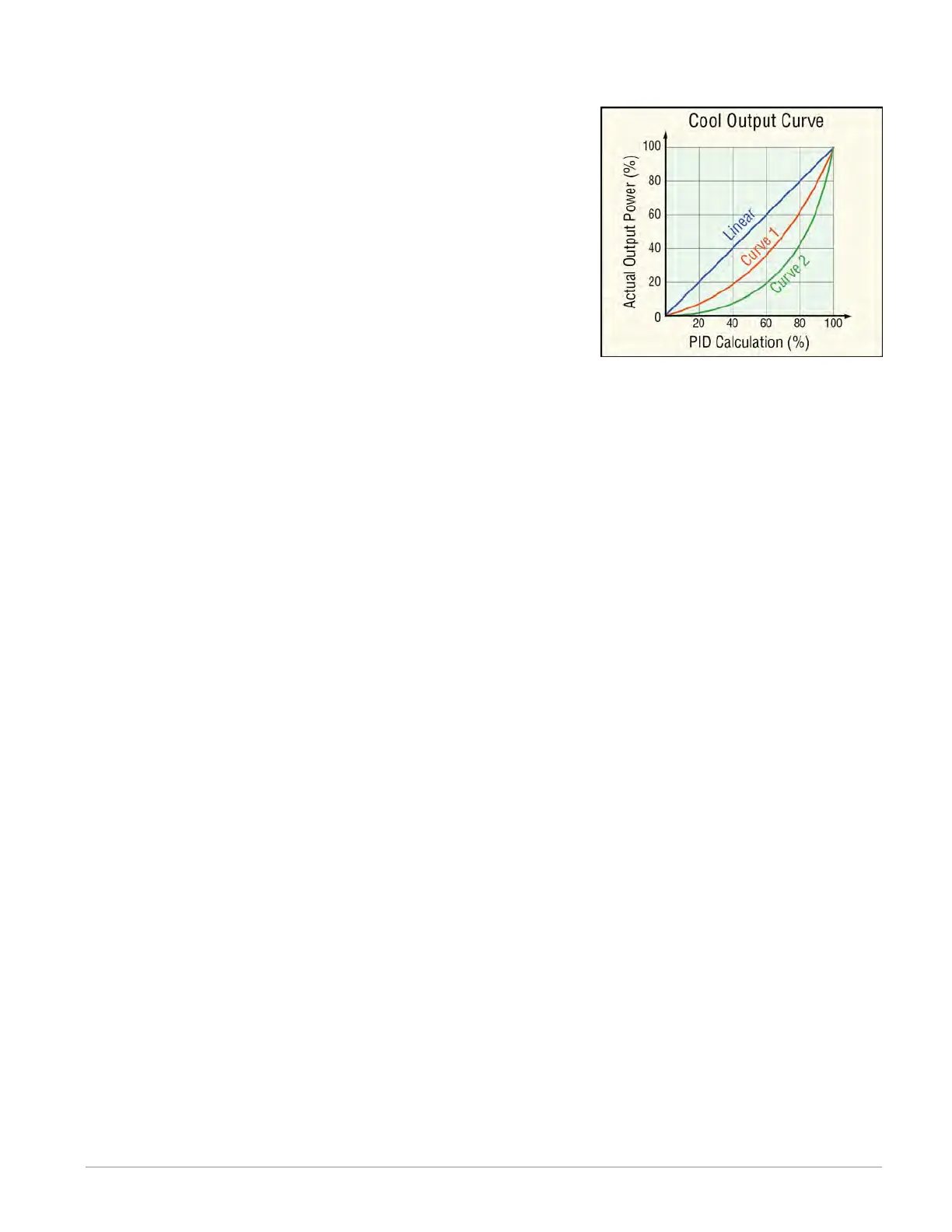

Cool Output Curve

Choose a cool output curve to set the responsiveness of the system. A nonlinear output curve

may improve performance when the system’s response is

nonlinear. With the nonlinear curves, a given change in the

PID calculation at the lower part of the output range yields

a smaller change in the actual output level than a linear

output provides.

This feature is used in applications such as cooling of plas-

tic extruders where a small amount of water cooling has a

large effect initially, but diminishing returns as water flow

increases.

This parameter applies only when Cool Algorithm is set to

PID.

Options:

• Off: the calculated PID value is applied linearly to the output.

• Non-linear Curve 1: somewhat non-linear response such as with oil coolant.

• Non-linear Curve 2: greater non-linear response such as with water coolant.

Profile End Action

Select what the cascade loop does when a profile ends without an End Step programmed

within a profile. If a profile has an End Step, it will always take precedence over this setting.

Options:

• User: controls at the current Set Point setting prior to execution of the profile.

• Off: control mode set to off

• Hold: maintain the last set point within the profile

Auto-to-Manual Power

Choose how the Manual Power is set when the user switches Control Mode from auto to man-

ual.

Options:

• Off: Manual Power is set to 0%.

• Bumpless Transfer: Manual Power is set equal to the last calculated value as long as

the output was less than 75% and stable. Stable is defined as varying by no more than

±5% over the Integral setting or a minimum of 10 seconds. Otherwise, Manual Power is

set to 0%

• Fixed Power: Manual Power is set equal to the Fixed Power setting

• User: uses the current Manual Power setting

Loading...

Loading...