Watlow F4T • 75 • Chapter 4 Application Examples

Application Tips:

• The profile engine block is initially located in the library and can be dragged to the

canvas.

• The signal from the input to PV1 on the profile engine lets the profile engine monitor

the process value when guaranteed soak is used and to establish the initial set point

when starting a profile.

• The signal from SP1 on the profile engine to PSP on the control loop allows the profile

engine to control the loop’s set point.

• If you want to be able to have a profile wait for a specific process value, connect the

process value signal to the EVT1 receiver (left side of the profile engine).

• The door switch signal to EVT2 on the profile engine allows profiles to be programmed

to wait for the door to be open or closed.

• The signal from the EVT1 transmitter (right side of the profile engine) to the test acti-

vation output allows the profile to enable an external circuit to power the parts under

test at the appropriate times.

• Enter names for blocks where possible to make the application easier to understand.

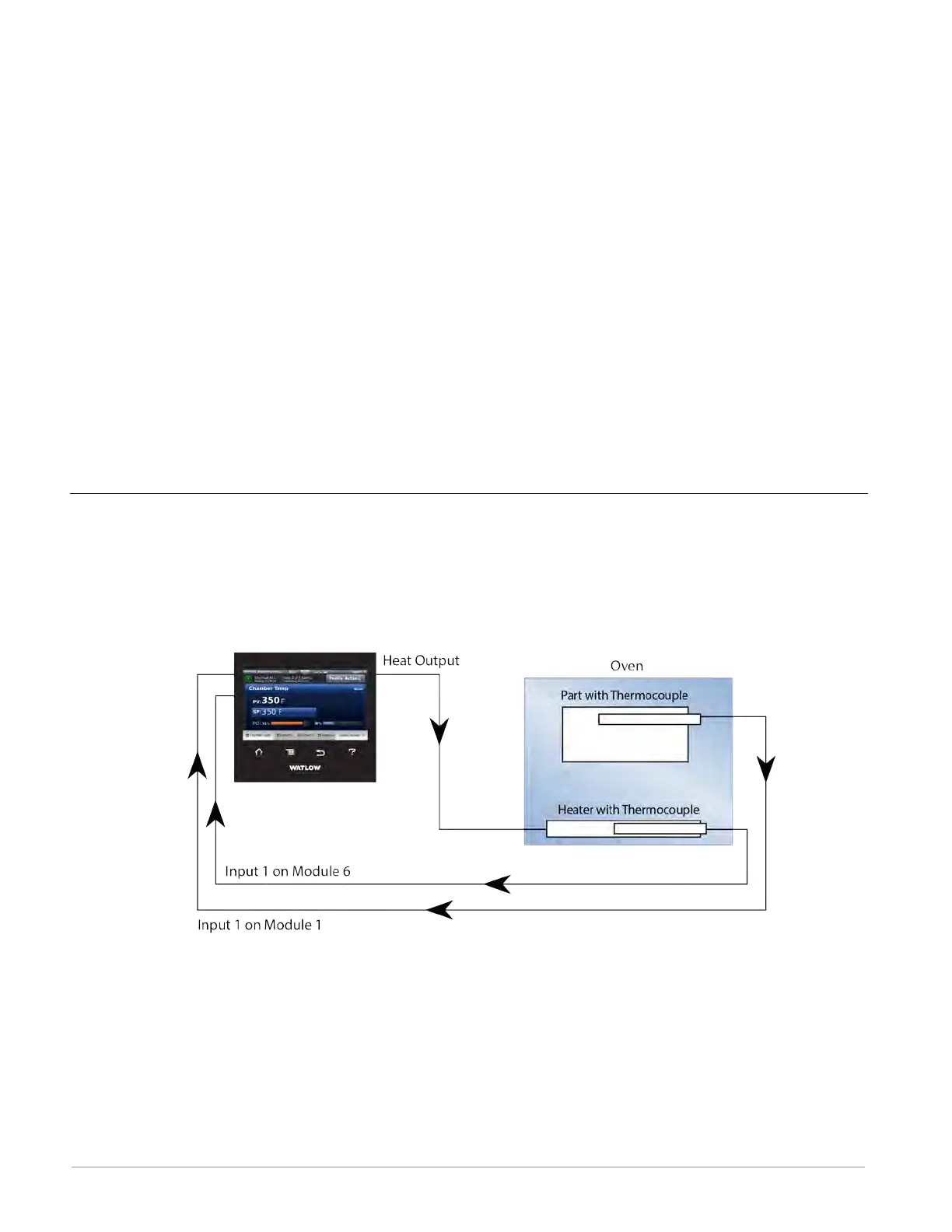

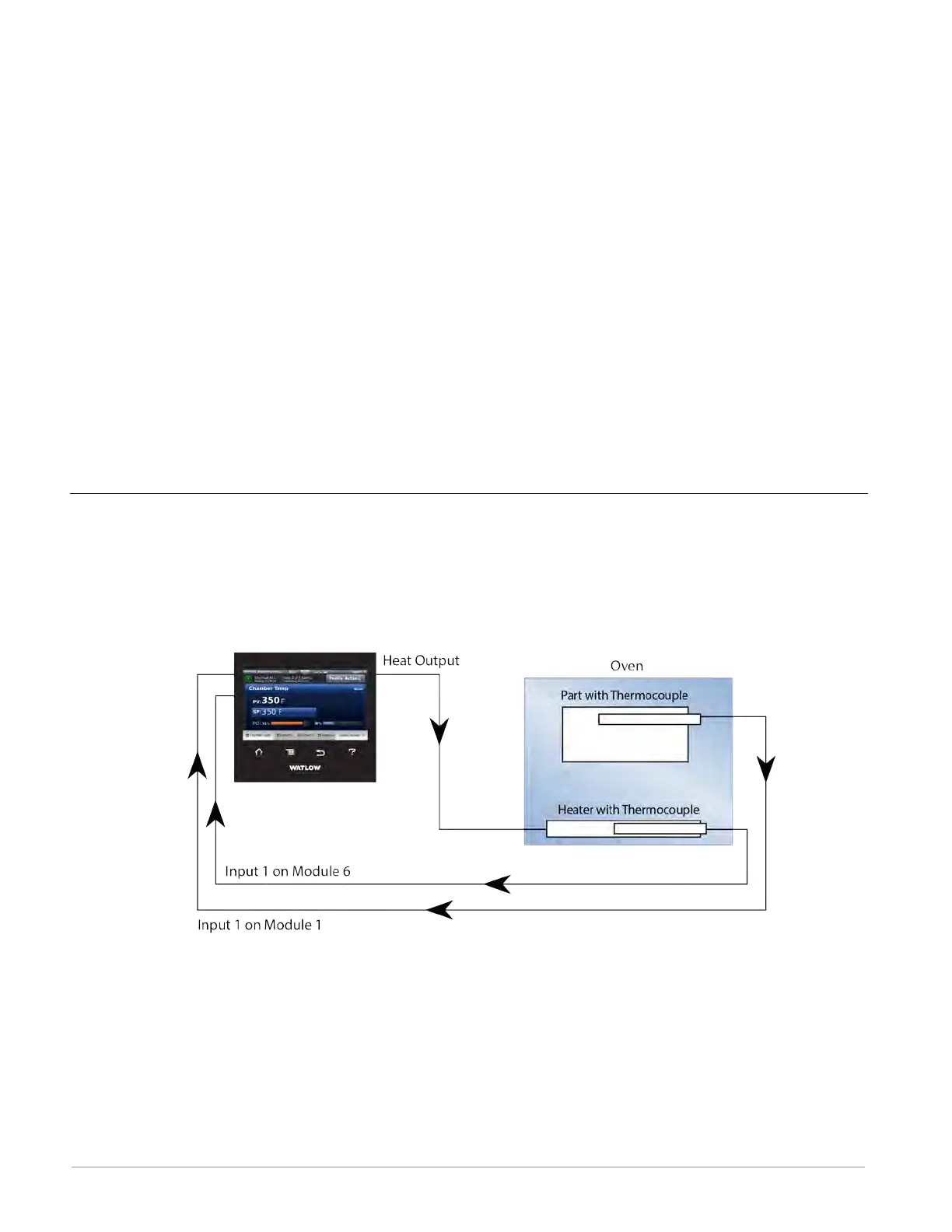

Cascade Control

In this example a part is heated in an oven. The part takes a lot longer to heat up than the

heater and oven, and it can be damaged if heated so quickly that the temperature on the sur-

face is a lot higher than the interior temperature. To heat the part in the minimum amount of

time while protecting it from excessive thermal stress, two temperature sensors are used and

the controller is configured for cascade control.

Loading...

Loading...