4-38 WorkCentre C2424 Service Manual

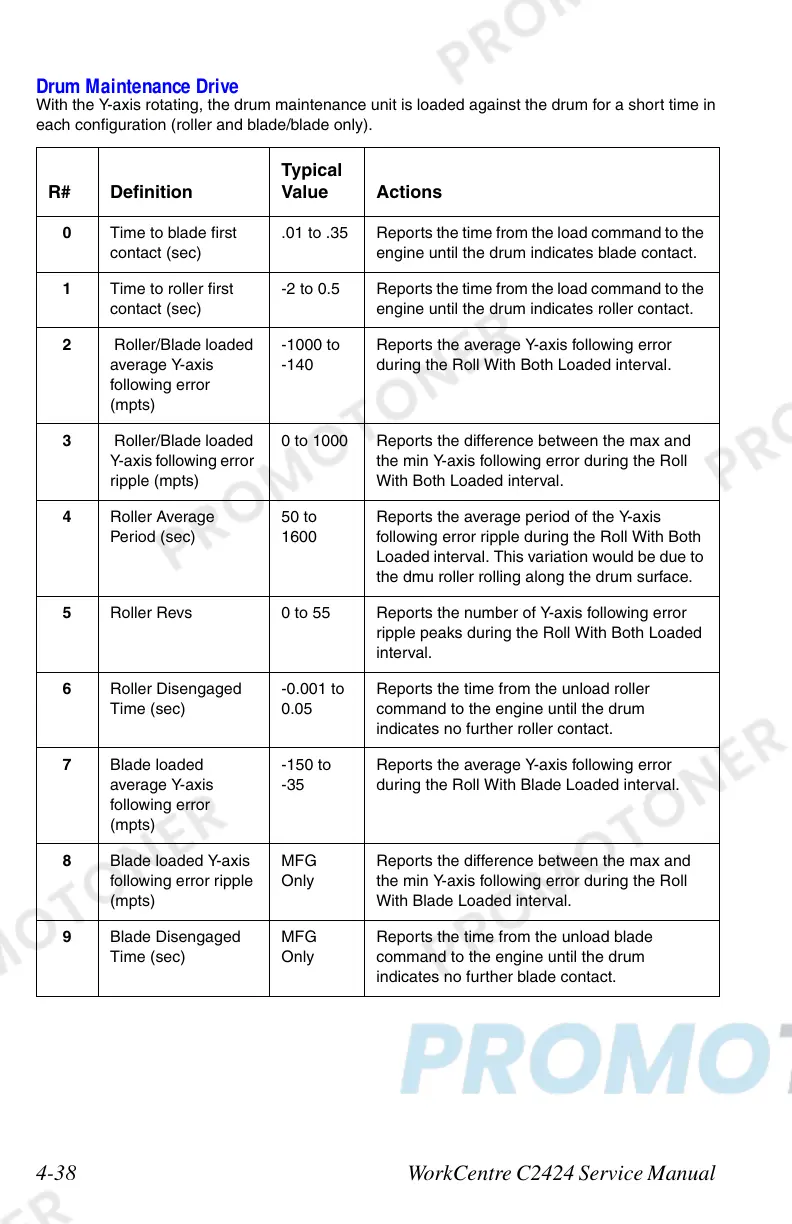

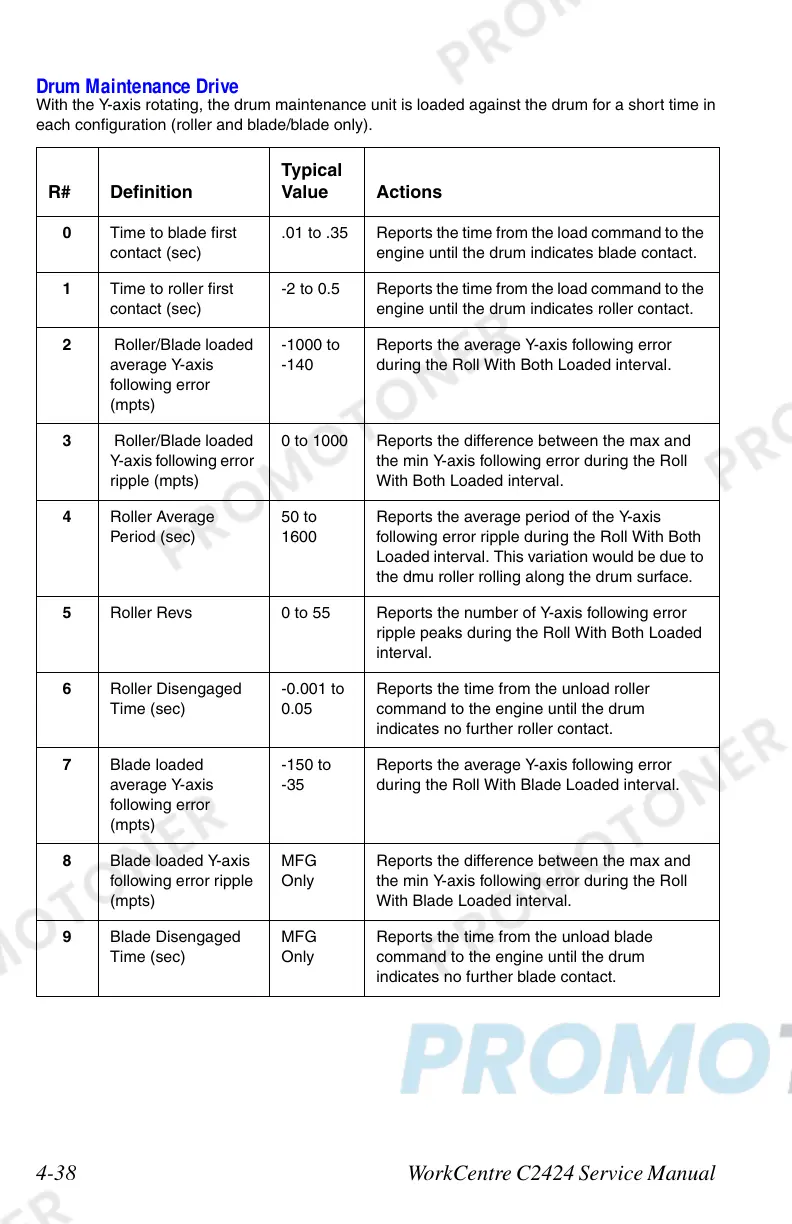

Drum Maintenance Drive

With the Y-axis rotating, the drum maintenance unit is loaded against the drum for a short time in

each configuration (roller and blade/blade only).

R# Definition

Typical

Value Actions

0 Time to blade first

contact (sec)

.01 to .35 Reports the time from the load command to the

engine until the drum indicates blade contact.

1 Time to roller first

contact (sec)

-2 to 0.5 Reports the time from the load command to the

engine until the drum indicates roller contact.

2 Roller/Blade loaded

average Y-axis

following error

(mpts)

-1000 to

-140

Reports the average Y-axis following error

during the Roll With Both Loaded interval.

3 Roller/Blade loaded

Y-axis following error

ripple (mpts)

0 to 1000 Reports the difference between the max and

the min Y-axis following error during the Roll

With Both Loaded interval.

4 Roller Average

Period (sec)

50 to

1600

Reports the average period of the Y-axis

following error ripple during the Roll With Both

Loaded interval. This variation would be due to

the dmu roller rolling along the drum surface.

5 Roller Revs 0 to 55 Reports the number of Y-axis following error

ripple peaks during the Roll With Both Loaded

interval.

6 Roller Disengaged

Time (sec)

-0.001 to

0.05

Reports the time from the unload roller

command to the engine until the drum

indicates no further roller contact.

7 Blade loaded

average Y-axis

following error

(mpts)

-150 to

-35

Reports the average Y-axis following error

during the Roll With Blade Loaded interval.

8 Blade loaded Y-axis

following error ripple

(mpts)

MFG

Only

Reports the difference between the max and

the min Y-axis following error during the Roll

With Blade Loaded interval.

9 Blade Disengaged

Time (sec)

MFG

Only

Reports the time from the unload blade

command to the engine until the drum

indicates no further blade contact.

Loading...

Loading...