5.16 Electronic Gear Settings

5.16.2 Electronic Gear Ratio Setting Examples

5-50

5.16.2

Electronic Gear Ratio Setting Examples

Setting examples are provided in this section.

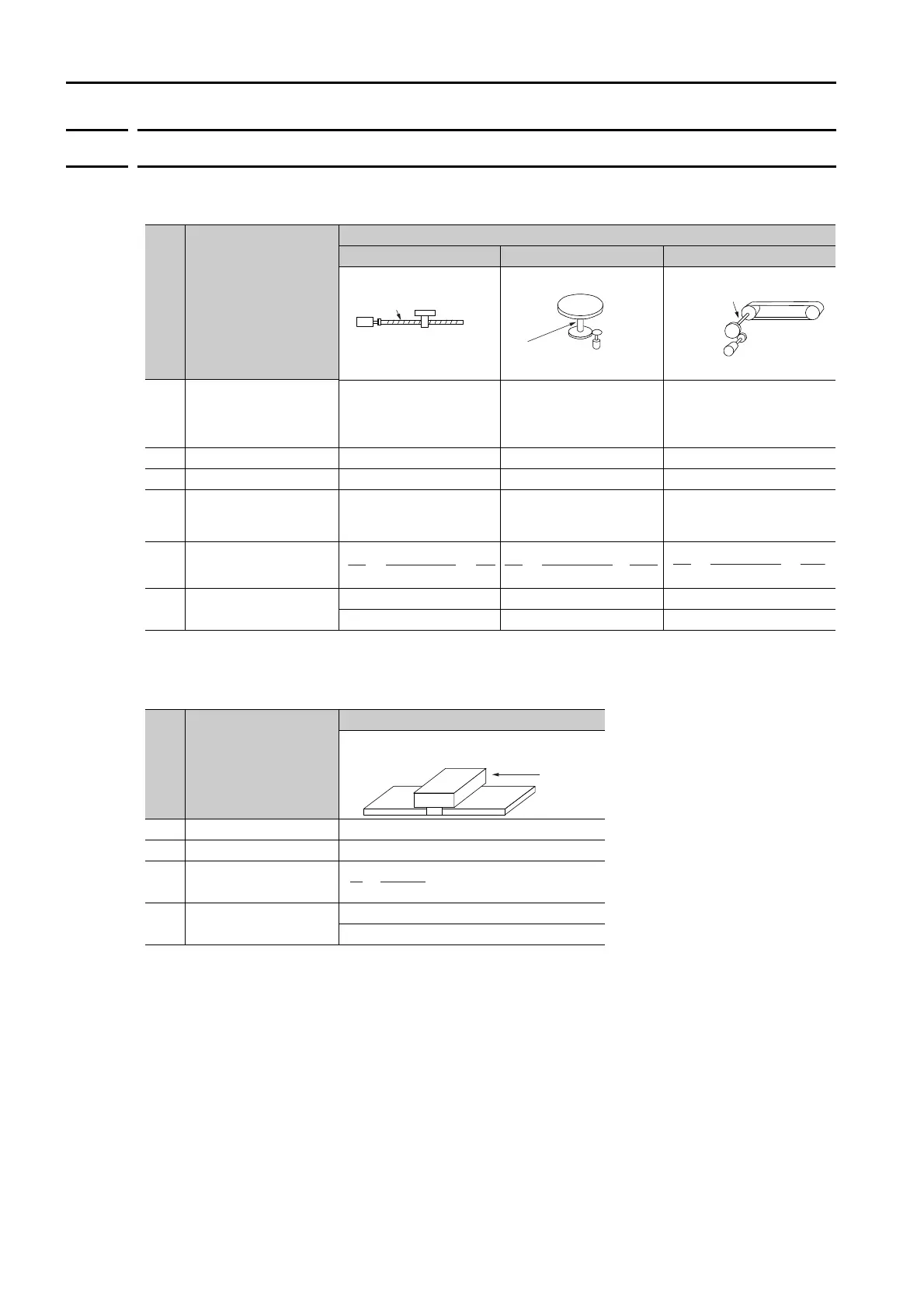

• Rotary Servomotors

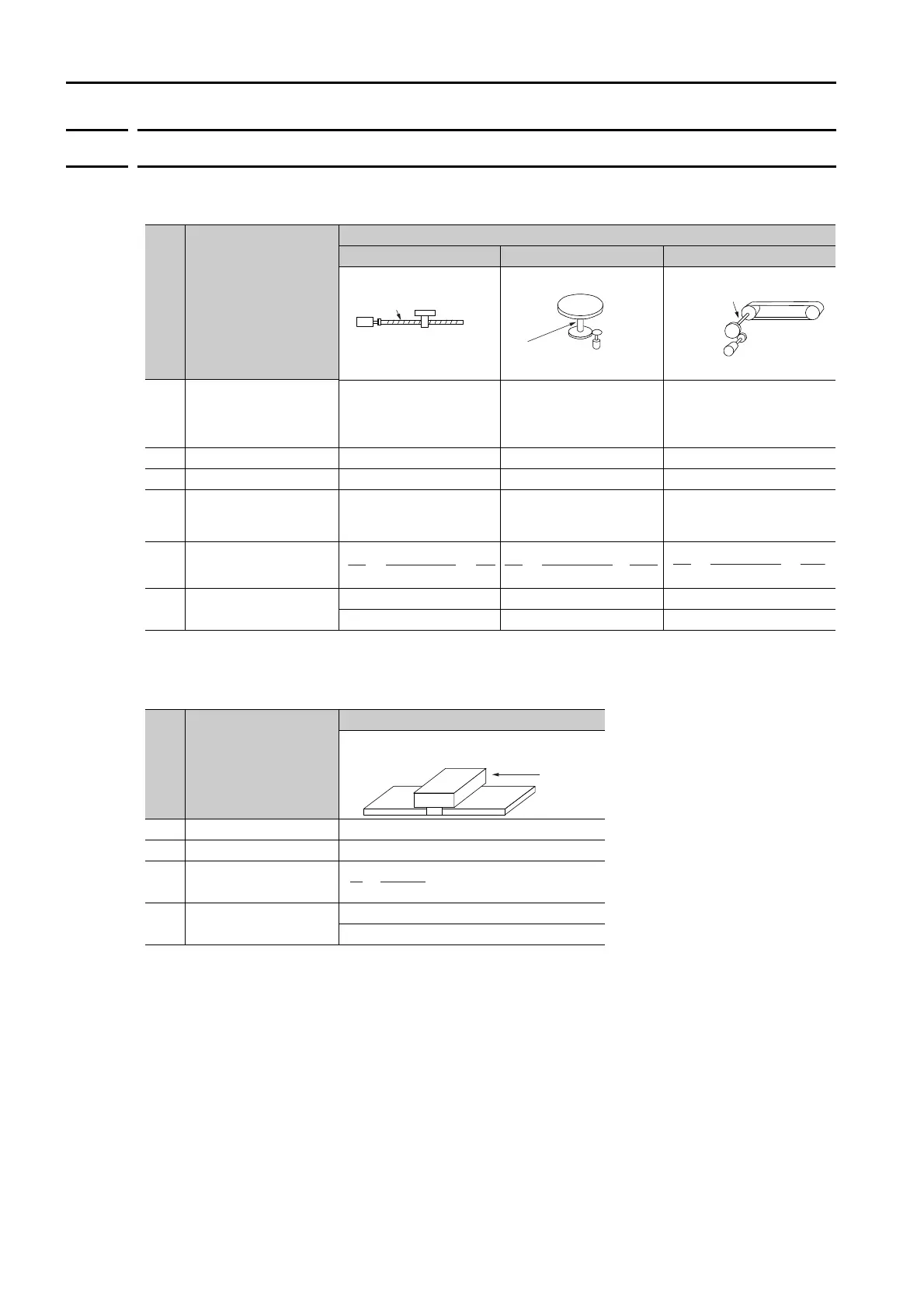

• Linear Servomotors

A setting example for a Serial Converter Unit resolution of 256 is given below.

Step Description

Machine Configuration

Ball Screw Rotary Table Belt and Pulley

1

Machine

Specifications

• Ball screw lead: 6 mm

• Gear ratio: 1/1

•

Rotation angle per revo-

lution: 360

°

• Gear ratio: 1/100

• Pulley dia.: 100 mm

(Pulley circumference:

314 mm)

• Gear ratio: 1/50

2 Encoder Resolution 16,777,216 (24 bits) 16,777,216 (24 bits) 16,777,216 (24 bits)

3 Reference Unit 0.001 mm (1 μm) 0.01° 0.005 mm (5 μm)

4

Travel Distance per

Load Shaft Revolution

(Reference Units)

6 mm/0.001 mm =

6,000

360°/0.01° = 36,000

314 mm/0.005 mm =

62,800

5 Electronic Gear Ratio

6 Parameters

Pn20E: 16,777,216 Pn20E: 1,677,721,600 Pn20E: 838,860,800

Pn210: 6,000 Pn210: 36,000 Pn210: 62,800

Step Description

Machine Configuration

1 Linear encoder pitch 0.02 mm (20 μm)

2 Reference Unit 0.001 mm (1 μm)

3 Electronic Gear Ratio

4 Setting Parameters

Pn20E: 256

Pn210: 20

Reference unit: 0.001 mm

Load shaft

Encoder:

24 bits

Ball screw lead:

6 mm

Reference unit: 0.01°

Load shaft

Encoder: 24 bits

Gear ratio:

1/100

Reference unit: 0.005 mm

Load shaft

Gear ratio:

1/50

Pulley dia.:

100 mm

Encoder: 24 bits

16,777,216

6,000

1

1

=

×

B

A

B

A

16,777,216

36,000

100

1

=

×

B

A

16,777,216

62,800

50

1

=

×

Reference unit:

0.02 mm (20 m)

Forward direction

Loading...

Loading...