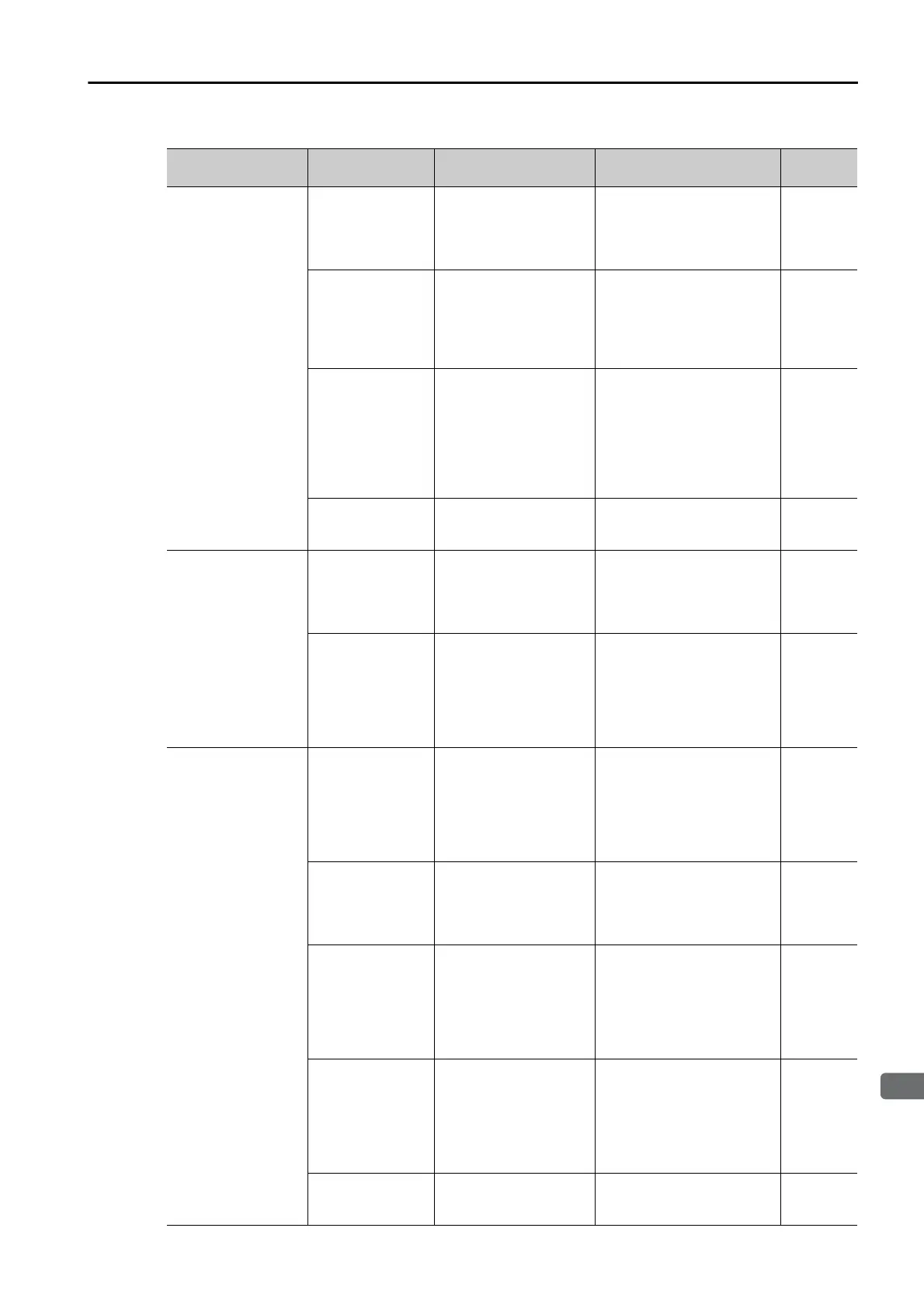

12.3 Warning Displays

12.3.2 Troubleshooting Warnings

12-47

A.910:

Overload (warning

before an A.710 or

A.720 alarm occurs)

The wiring is not

correct or there is

a faulty contact in

the motor or

encoder wiring.

Check the wiring.

Make sure that the Servo-

motor and encoder are cor-

rectly wired.

–

Operation was

performed that

exceeded the

overload protec-

tion characteris-

tics.

Check the motor over-

load characteristics and

Run command.

Reconsider the load and

operating conditions. Or,

increase the motor capacity.

–

An excessive load

was applied

during operation

because the Ser-

vomotor was not

driven because of

mechanical prob-

lems.

Check the operation

reference and motor

speed.

Remove the mechanical

problem.

–

A failure occurred

in the SERVO-

PACK.

–

The SERVOPACK may be

faulty. Replace the SERVO-

PACK.

–

A.911:

Vibration

Abnormal vibra-

tion was detected

during motor

operation.

Check for abnormal

motor noise, and check

the speed and torque

waveforms during oper-

ation.

Reduce the motor speed.

Or, reduce the servo gain

with custom tuning.

page 8-42

The setting of

Pn103 (Moment of

Inertia Ratio) is

greater than the

actual moment of

inertia or was

greatly changed.

Check the moment of

inertia ratio or mass

ratio.

Set Pn103 (Moment of Iner-

tia Ratio) to an appropriate

value.

–

A.912:

Internal Tempera-

ture Warning 1

(Control Board Tem-

perature Error)

The surrounding

temperature is too

high.

Check the surrounding

temperature using a

thermostat. Or, check

the operating status

with the SERVOPACK

installation environ-

ment monitor.

Decrease the surrounding

temperature by improving

the SERVOPACK installa-

tion conditions.

–

An overload alarm

was reset by turn-

ing OFF the power

supply too many

times.

Check the alarm display

to see if there is an

overload alarm.

Change the method for

resetting the alarm.

–

There was an

excessive load or

operation was

performed that

exceeded the

regenerative pro-

cessing capacity.

Use the accumulated

load ratio to check the

load during operation,

and use the regenera-

tive load ratio to check

the regenerative pro-

cessing capacity.

Reconsider the load and

operating conditions.

–

The SERVOPACK

installation orien-

tation is not cor-

rect or there is

insufficient space

around the SER-

VOPACK.

Check the SERVO-

PACK installation con-

ditions.

Install the SERVOPACK

according to specifications.

page 3-3,

page 3-5

A failure occurred

in the SERVO-

PACK.

–

The SERVOPACK may be

faulty. Replace the SERVO-

PACK.

–

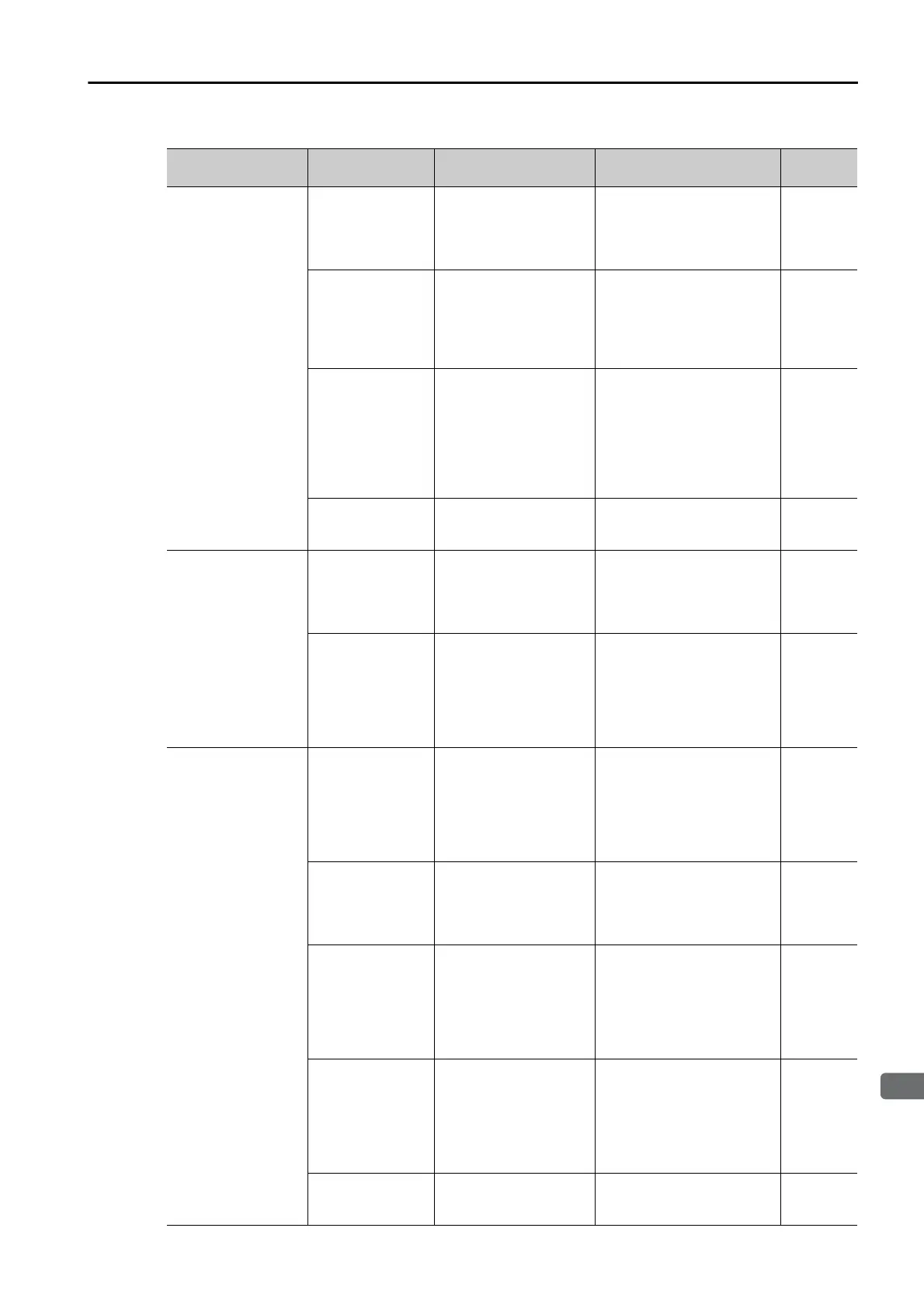

Continued from previous page.

Warning Number:

Warning Name

Possible Cause Confirmation Correction Reference

Loading...

Loading...