3.2.2 Maintenance schedule

General

The track motion must be maintained regularly to ensure proper function. The

maintenance activities and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the track. Any damages

must be attended to immediately!

The inspection intervals do not specify the life of each component. Values for these

are specified in the section Expected component life on page 154

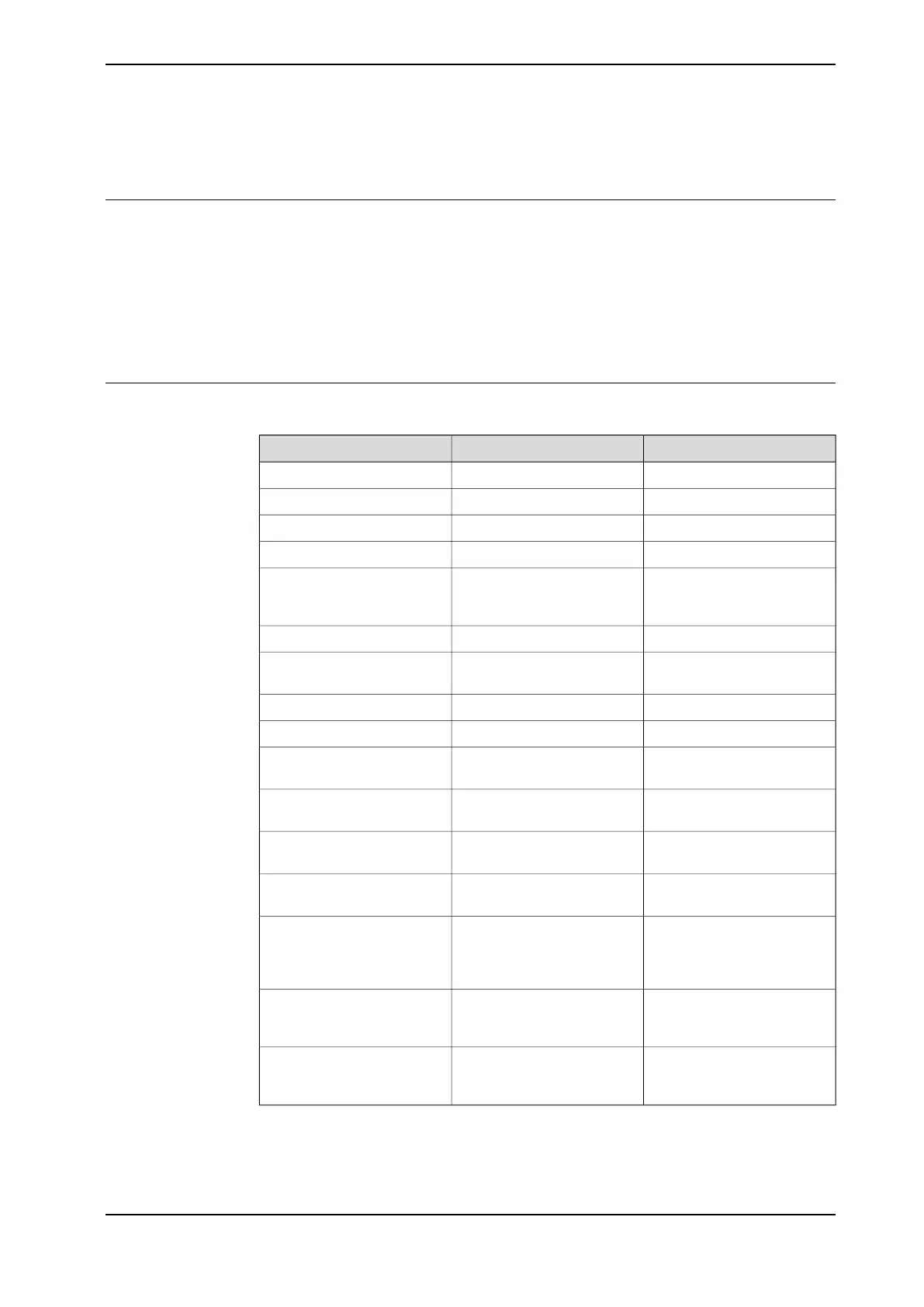

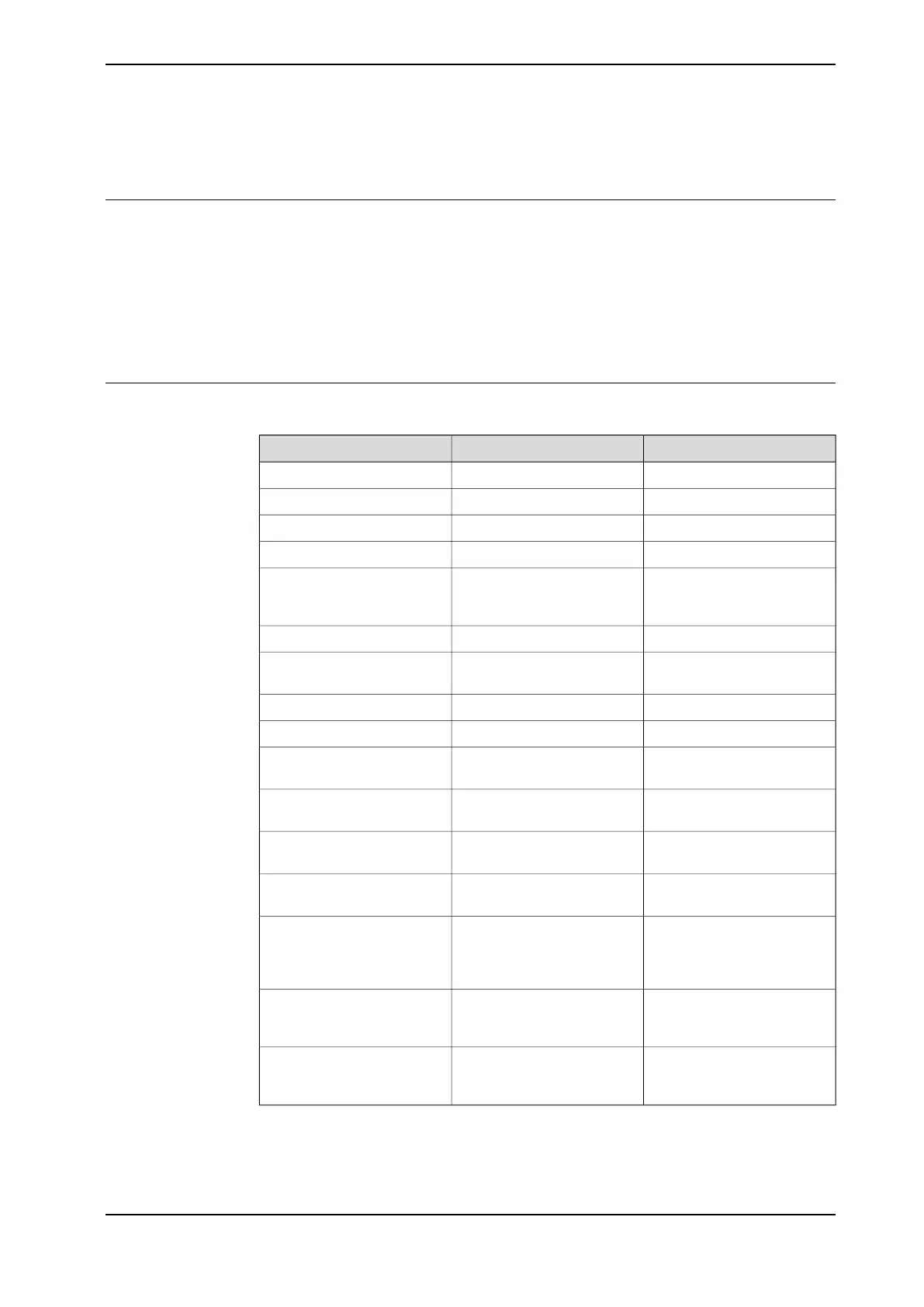

Activities and intervals, standard equipment

The table below specifies the required maintenance activities and intervals.

IntervalEquipmentMaintenance activity

Every 100 kmLinear guidesCleaning

Every 3 monthsCable chainInspection

Every 3 monthsLinear guidesInspection

Every 3 monthsFelt gearInspection

Every 12 monthsCables and connectors at ro-

bot base, track motor and in-

terchange to floor cable

Inspection

Every 12 monthsMechanical stopsInspection

Every 12 monthsGear wheel, gearbox and

backlash

Inspection

Every 12 monthsFitting boltsInspection

Every 12 monthsComplete trackAdjustment of leveling

When expected life is reached

or if disturbances occur.

Linear guideReplacement

When linear guides are re-

placed.

Ball bearing blocksReplacement

When play can not be adjus-

ted to specified

i

level.

Felt gear, gear wheel, gear-

box and racks

Replacement

When gliding surface thick-

ness is 1.5 mm or less.

iii

Glide shoes

ii

Replacement

36 months or battery low alert

iv

Battery pack, measurement

system of type RMU101 or

RMU102 (3-pole battery con-

tact)

Replacement

Battery low alert

v

Battery pack, measurement

system with 2-pole battery

contact, e.g. DSQC633A

Replacement

Every 1 month or sensor alert

(option 1475-1 Oil Detection

sensor)

vi

.

Automatic lubrication systemCheck the level

i

The play is specified in Adjusting the gearbox backlash on page 229.

ii

Glide shoes have been introduced to simplify and reduce the time associated with changing links.

iii

The first glide shoes to wear out will be located at the point where the chain first makes contact

with itself during operation.

Continues on next page

Product manual - IRBT 2005 151

3HAC051130-001 Revision: F

© Copyright 2015 - 2018 ABB. All rights reserved.

3 Maintenance

3.2.2 Maintenance schedule

Loading...

Loading...