4.6.3 Replacing the gear wheel

Location of motor and gear

Users can choose to change the whole geared motor unit to reduce down time or

only change the malfunctioned gear or motor. It is recommended to have two

technicians to work together.

To replace the motor and/or the gear, it is possible to remove the motor bracket

from the top plate and then push the carriage away. It is recommended to have

two technicians to work together.

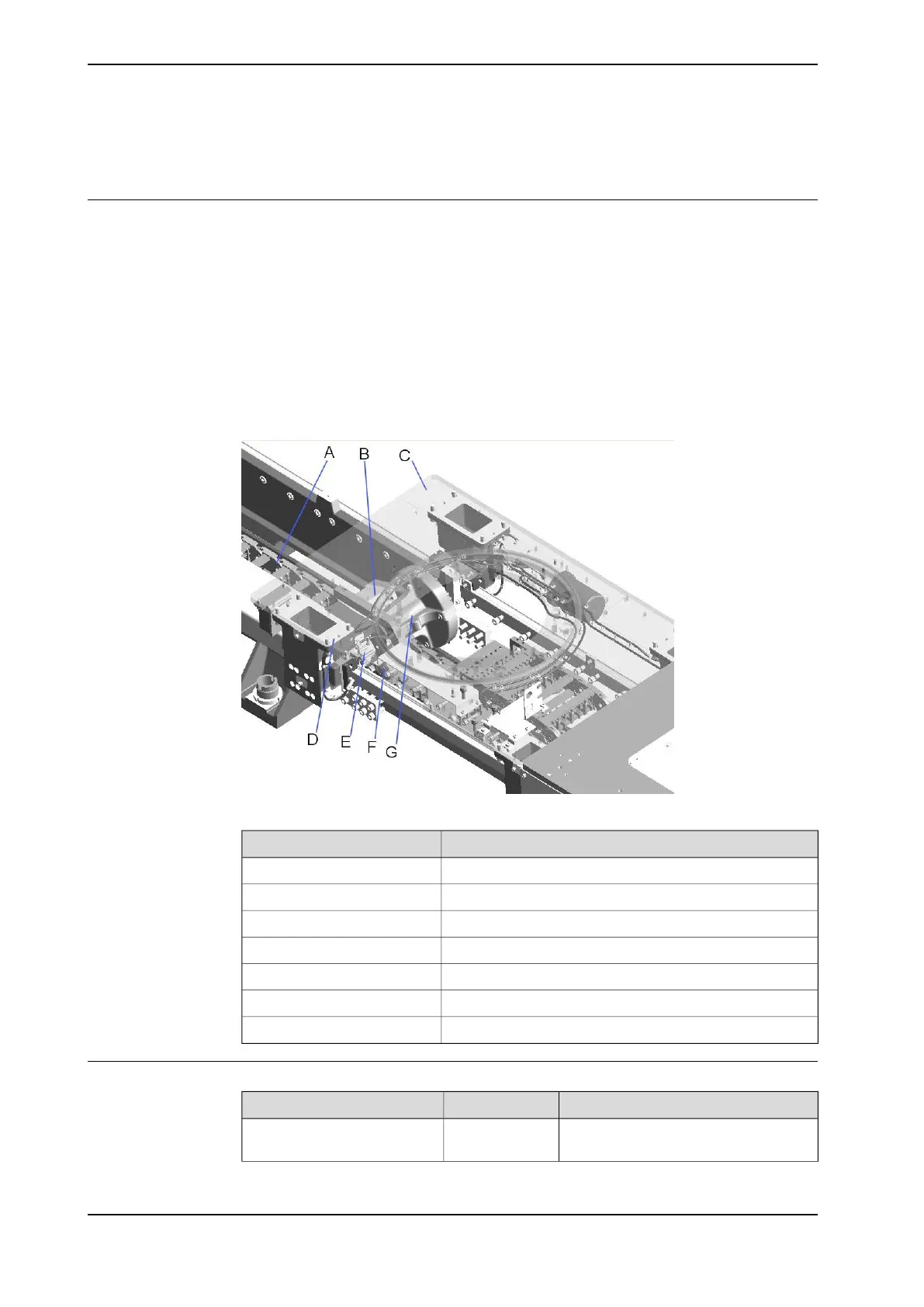

The figure below shows how to push the carriage away from the motor bracket

and expose the motor, gearbox, gear wheel, felt gear and cable chain connection

point. This makes the following components accessible for maintenance:

xx1400002684

NameItem

Cable chain - remains stationeryA

Motor - remains stationeryB

Carriage - pushed awayC

Motor bracket - remains stationeryD

Gear wheel - remains stationeryE

Felt gear - remains stationeryF

Gearbox - remains stationeryG

Required equipment

NoteArt. No.Equipment

The content is defined in Standard tools

on page 276.

-Standard toolkit

Continues on next page

216 Product manual - IRBT 2005

3HAC051130-001 Revision: F

© Copyright 2015 - 2018 ABB. All rights reserved.

4 Repair

4.6.3 Replacing the gear wheel

Loading...

Loading...