Tension Electronics PFEA111/112, User Manual

Chapter 3 Commissioning

3-6 3BSE029380R0101 Rev C

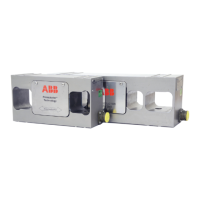

3.8.1 Performing Fast Setup using Hanging Weights

The simplest method to set the wrap gain in this tension system is to use a known weight that

loads the center of the roll with a rope that follows the web path exactly.

Figure 3-1. Setting Wrap Gain with Hanging Weights (example of installation)

Follow the steps below to run a fast setup using hanging weights.

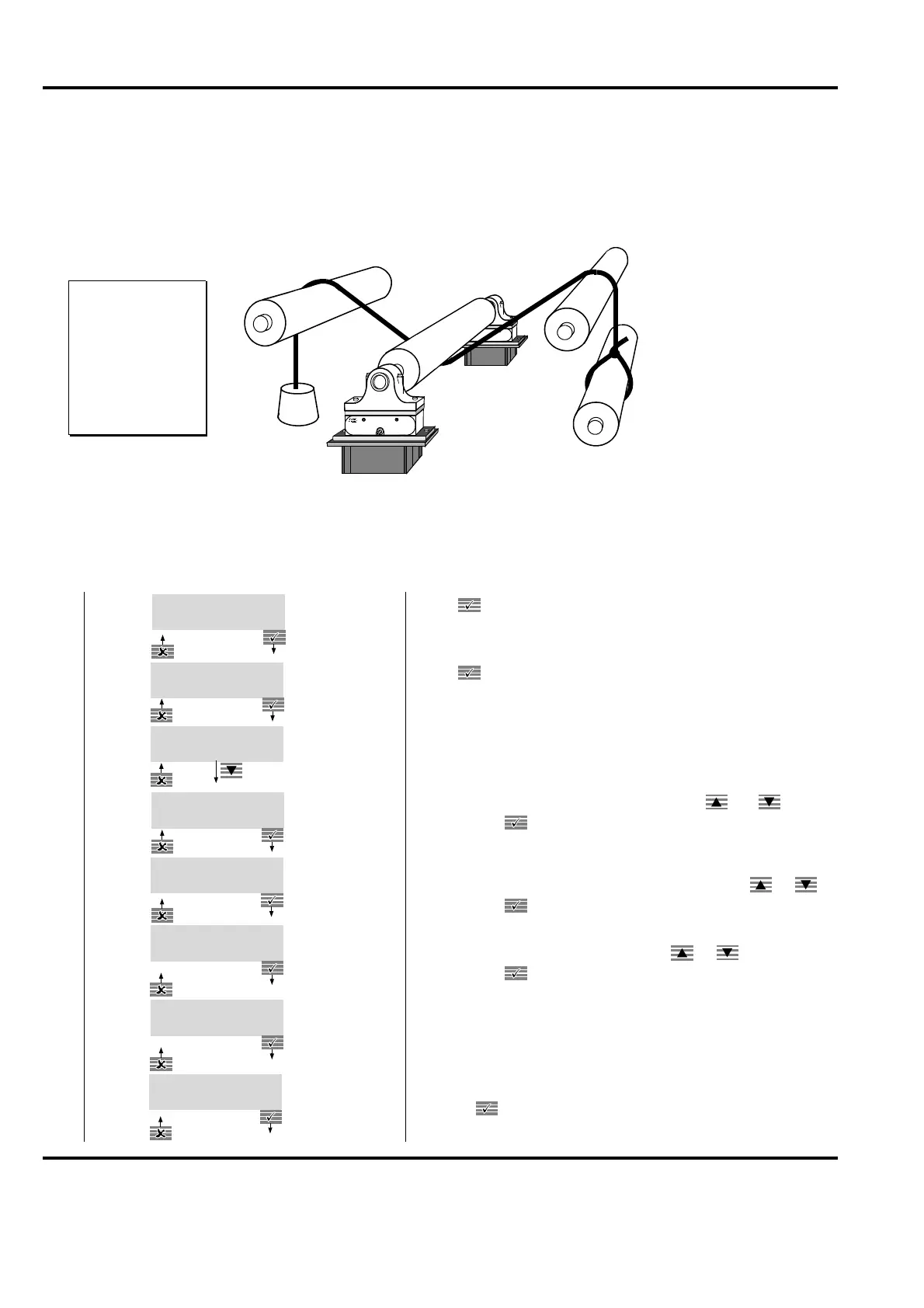

1Press for 5 seconds to go to the FastSetUp menu.

2Press to start the fast setup sequence.

3

The menu SetWebWidth will only be available when the

selected unit is N/m, kN/m, kg/m or pli.

Default Web Width is 2m (78,740 inch).

4Select HangingWeights from the list with and .

Confirm with .

5 Select the number of load cells that support the roll (2 or

Single Side A or Single Side B) from the list with or .

Confirm with .

6 Check the nominal load on the load cell name plate.

Select nominal load from the list with or .

Confirm with .

7

Zero set is used to compensate for load cell zero signal and

tare weight.

Zero set must be done with no tension applied to the roll.

8 1. Check that no load is applied on the roll.

2. Press to zero set. “ActionDone” is shown on the

display for one second to confirm the zero setting action.

Load cell

Weight

Rope

supported roll

All rolls must be

free turning idlers.

To keep friction

losses low, only

use the closest

rolls to define web

path.

SetWrapGain

[HangingWeights]

NominalLoad

[1 kN 225 lbs]

WithNoTension

PressOkToZeroSet

Loading...

Loading...