Agilent 7820 GC Service

231

To reduce the fire hazard when sampling

flammable gases or liquids under pressure,

operators should routinely make pressure-leak

tests of the plumbing, fitting and valves. Both

valve positions should be checked. Depending

on the nature and pressure of the sample

stream, periodic pressure leak test and visual

inspection should be made since wear or use

could cause leaks to develop. Leaks may occur

inside the valve box and be concealed from the

operators view.

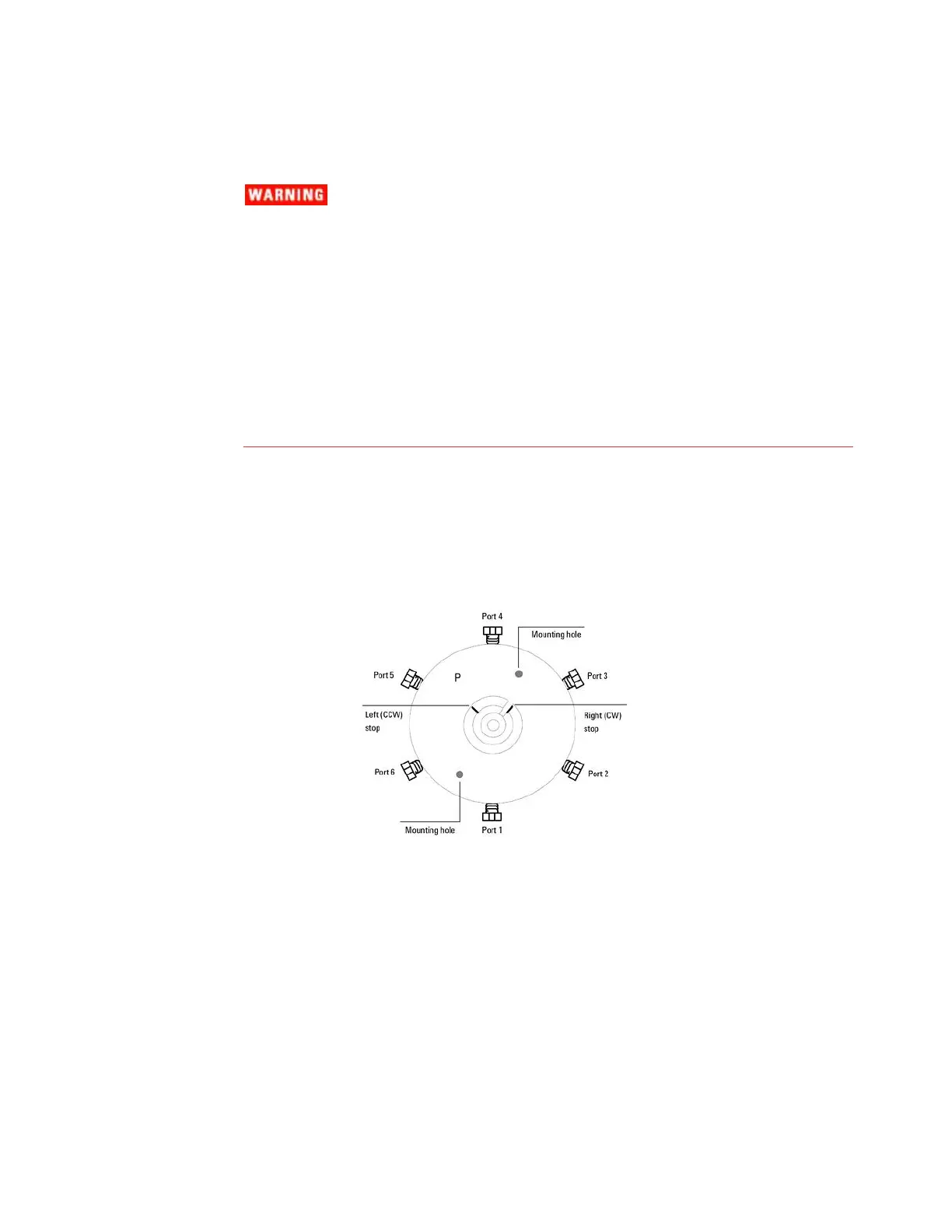

Valco W-series minivalves

Valves consist of a driver, valve body, rotor, and preload

assembly.

Valve bodies

Body parts are made from Nitronics 60 nickel steel. If required,

the valve may also be produced from Hastelloy C. External

tubing (plumbing) is connected to the valve body ports by

ferrules and fittings provided with the instrument.

The left (CCW, counterclockwise) and right (CW, clockwise)

stops on general purpose valve bodies limit rotor rotation so the

correct flow path results when the index pin is close to or against

either stop of the index lip.

Loading...

Loading...