Set Up and Maintenance

9836 3521 01 191

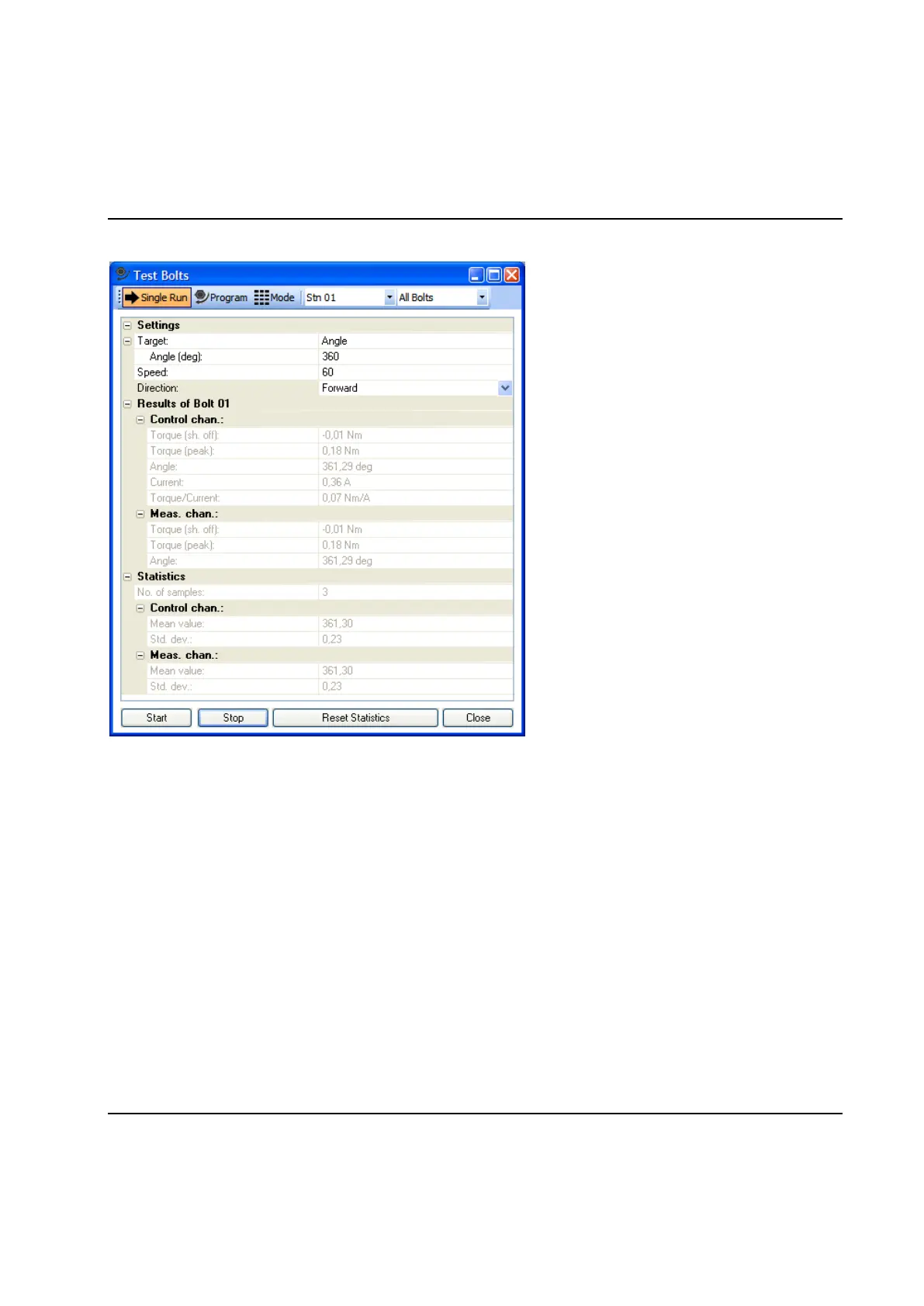

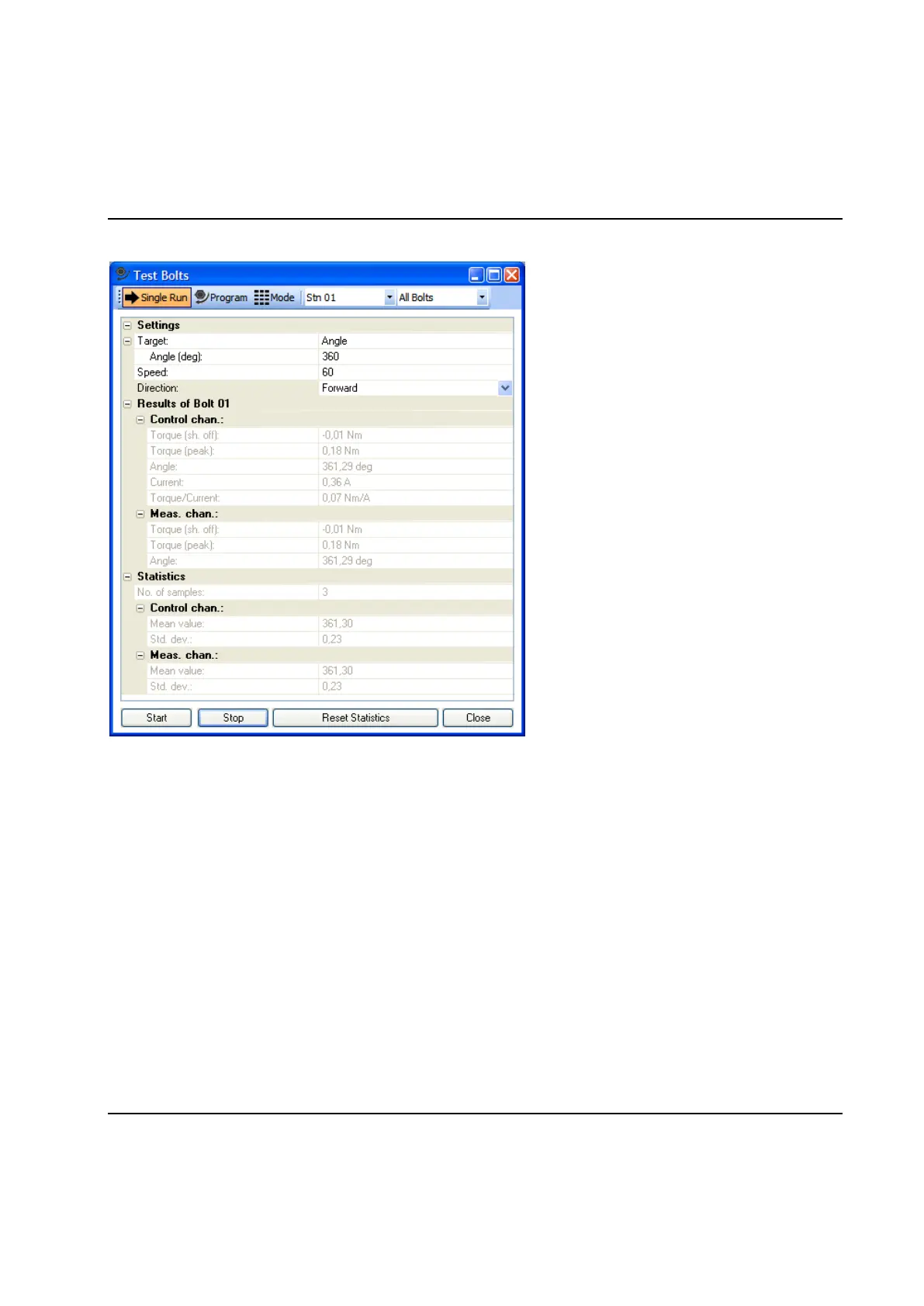

Single Run

When you use this function, you will automatically get some statistics directly on the screen. Do the

following:

Select a station.

Select a spindle.

Select a speed. The same speed as you have in the final tightening step in the normally used

program is a good choice.

Select the parameter you want to calibrate (Torque/Angle/Current) and a target value.

Reset the statistics.

Click on the Start button.

If you use the Stop function, the spindle will stop and a Machine Stop will be generated in the Event Log.

Note! When you use the “single run” function, there is no “zero-offset check and compensation” made.

This must be done manually by first running a tightening set that has a D - Diagnostic Step as a

first step. The “zero-offset” measured by it will automatically be stored and used until you either

run a new Diagnostic step, make a change in the Spindle Set Up form, or power off/on the TC.

Use the run “Program” alternative to do this.

Loading...

Loading...