Tightening

9836 3521 01 383

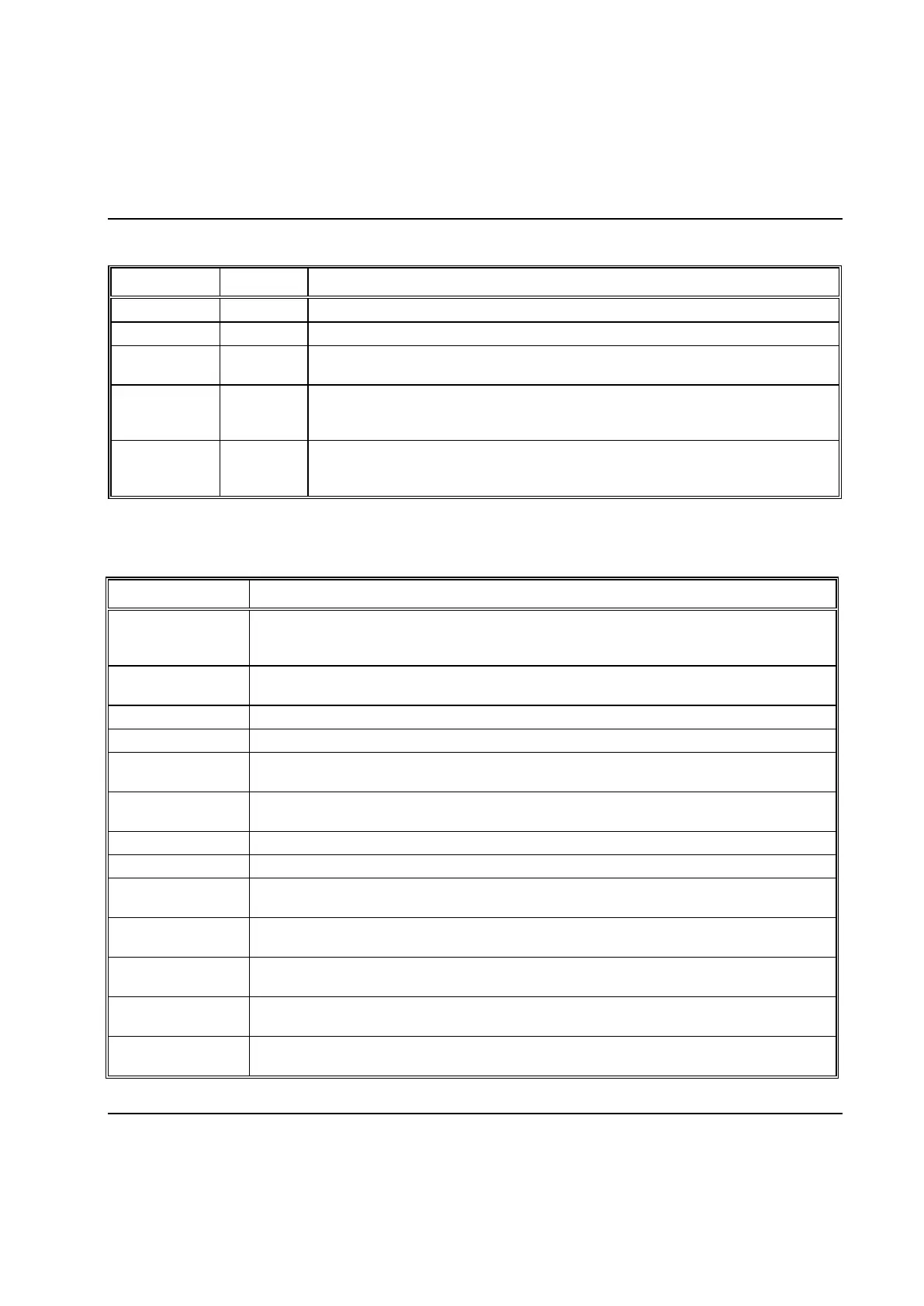

Bolt Status variables can take one of the following values:

Successful. No repairs have been made.

Successful. Errors have occurred but have been repaired

Not successful. This bolt failed to execute a step either due to a restriction, a

check or that any other fatal error occurred.

Not successful. An error occurred while running a terminate sequence (i.e. the

steps specified using “Terminate with step” on the Reject tab for a step). The

execution of steps was terminated when the error was found

Not successful only due to reject management. The bolt did not fail to execute a

step but was ordered to terminate, or not to finish the program, as a reject

management action.

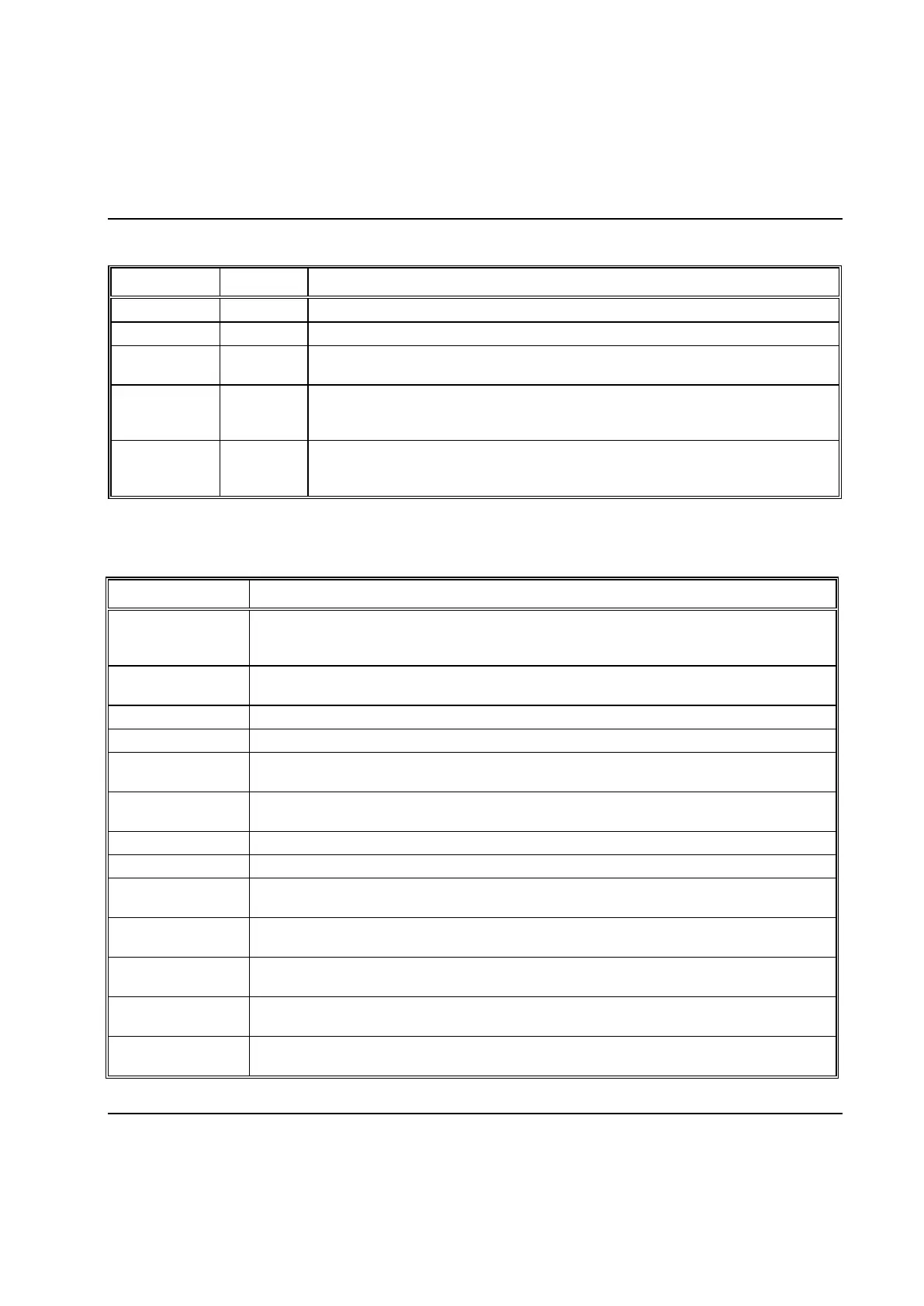

6.7.2 Station level result variables

The Station level contains information concerning the station that runs the tightening.

A device unique sequence number. This number is incremented by one for each cycle

data reported over the device in question. This number can be used to detect missing

cycles.

The name of the station. See System for how to set or change the name of a station. Max.

20 ASCII characters.

The number of the station. The first station in the system is 1.

The date and time when the cycle was started.

Work piece Identity. Supplied to station from an ID device (see ID device Set Up) or set by

the PLC using the IDSTRING output (Station variables). Max. 40 ASCII characters.

The name of the mode that was executed. Set using The Mode Table form. Max. 20 ASCII

characters.

The number of the mode that was executed.

Total status for the station: See chapter: Statuses for possible values.

Total number of cycles executed during the current shift. See Shift Reports and Shift Set

Up for a description of shifts.

Total number of cycles that ended OK or OKR during the current shift. See Shift Reports

and Shift Set Up for a description of shifts.

Total number of cycles that ended NOK or TERMNOK during the current shift. See Shift

Reports and Shift Set Up for a description of shifts.

The value of the PLC output FREESTRING when the cycle was started (see Station

variables).

The value of the PLC output FREENUM1 when the cycle was started (see Station

variables).

Loading...

Loading...