Tightening

9836 3521 01 361

6.5.5.7 Reject management examples

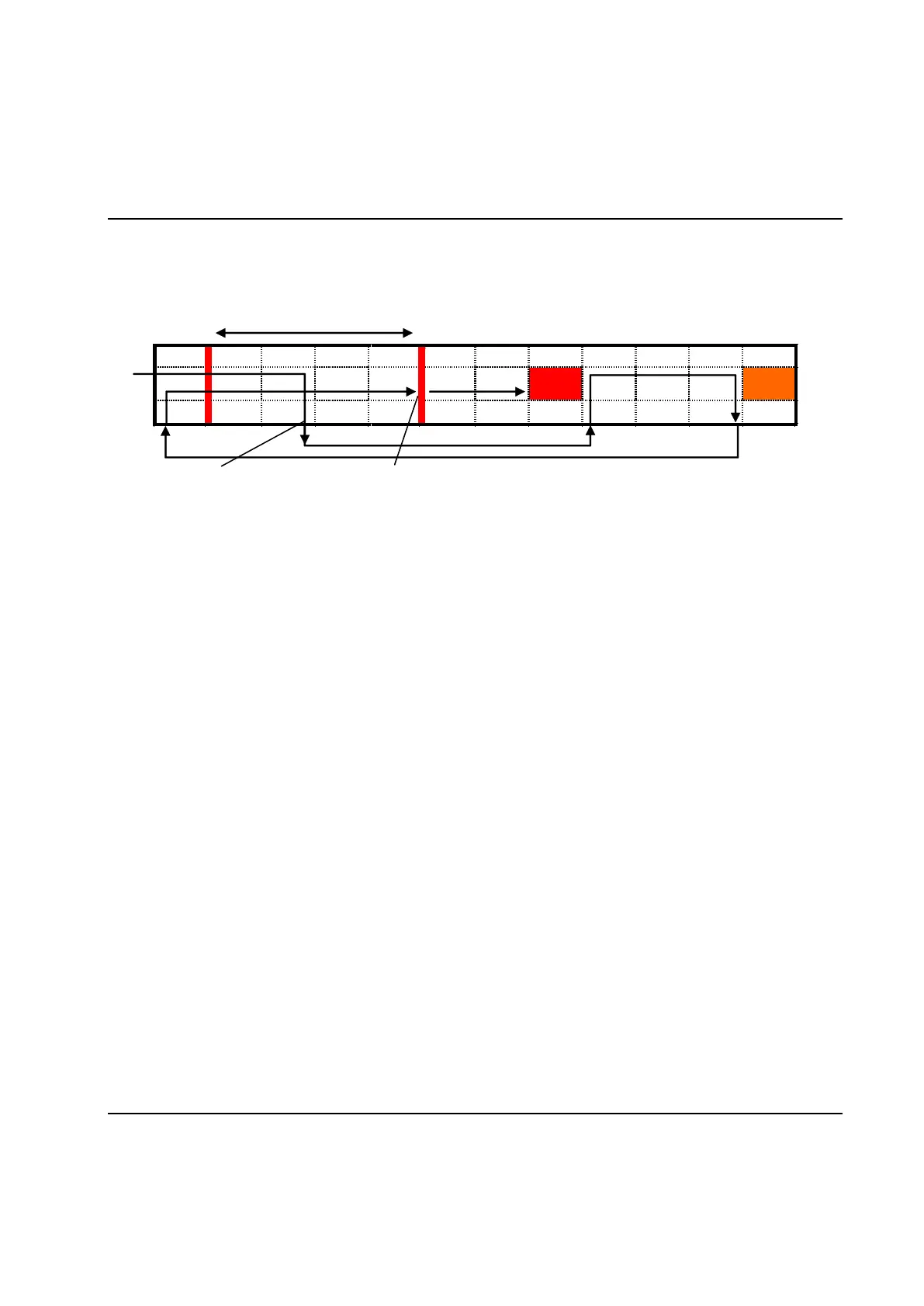

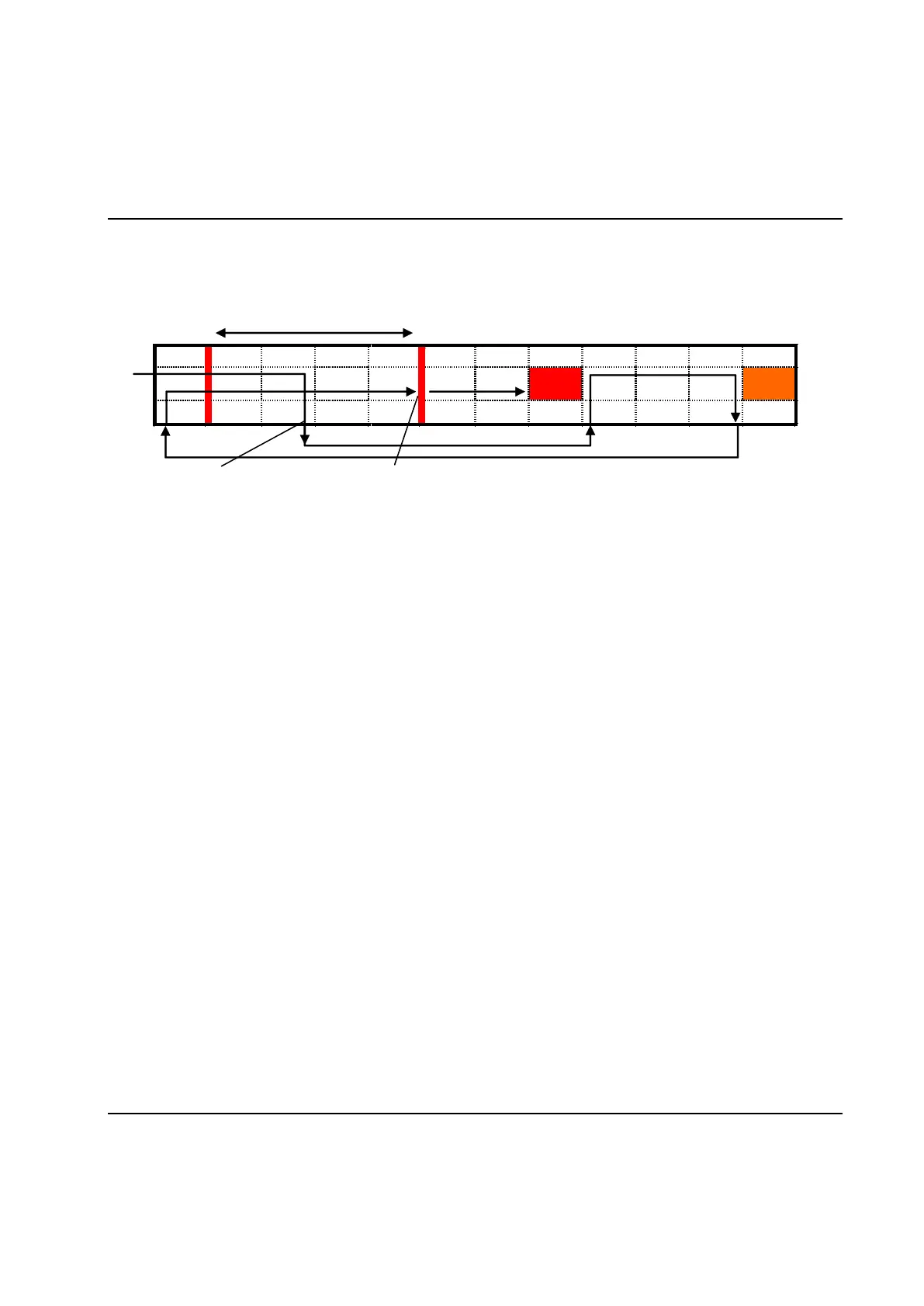

Failing

synchronization

interval

Here the bolt transfer from

state RUNNING REPAIR

to RUNNING NORMAL

Here the bolt transfer from

state RUNNING NORMAL

to RUNNING REPAIR

When the bolt fails the first time in step 3 the station will use the First failure settings of this step when

computing the reject management action.

In this case a Loosen with step sequence is defined (step 9 to 11) so when the station orders the bolt to

start repair the bolt will

Enter the Running Repair state

And jump to step 9

It will continue to execute without interaction with the station until it reaches a synchronization mark. Here

the bolt will stop after step 11 since step 12 is a Return from Repair (which is an implicit synchronization

mark). This ends the Loosen with step sequence.

Since Restart from step is set to 1 for the step 3 the bolt will jump to step 1 when it receives the next start

order from the station. Since step 1 has a synchronization mark the bolt will stop here and wait for a new

order from the station.

When the station sends the next start order the bolt will run until step 5 is finished. Since the bolt now

have reached its "Failing synchronization interval" it transfers from state Running Repair to the Running

Normal. The station will not order the bolt to start the next step until all other bolts that also are running

repair are finished.

When the next start order is received from the station the bolt will run until it reaches step 7 and at this

point report to the station that has finished the program.

When all bolts have finished their cycles the station will order the bolt to do monitoring checks. Monitoring

checks will be performed as configured in step 8.

Loading...

Loading...