Tightening

362 9836 3521 01

Alternative sequences:

Should the bolt fail while executing step 1 the second time (that is, while Running Repair) it would cause a

new reject management action according to the Failure during repair settings of step 1. This since it has

not yet reached its "Failing synchronization interval".

Should the bolt fail to execute one of the steps 2, 3, 4 or 5 the second time it will immediately return to the

Running Normal state since it reached its "Failing synchronization interval". The station would then wait

until all bolts is in the Running Normal state and then compute a new reject action according to the First

failure settings of the failing step (2, 3, 4 or 5).

Should the Initiate repair steps end by a CE step the cycle ends at step 11 and monitoring and cycle RM is

performed according to step 12. If some monitoring check fails repairable First failure settings for the step

are used to determine the action. Fatal errors cause Fatal failure settings to be used.

When step 11 has been run the bolt reports step status and that it has reached cycle end and RM end. If

there was an error when running step 11 it is handled with Failure during repair settings. If there are other

bolts still running when the repair is ready the station will order the bolt at CE too to run next step, upon

which the bolt repeats that cycle end is reached and changes state to Running Normal. After this the bolt

might be ordered to retry or to terminate, due to other reject bolts.

If some of the bolts in the system run longer cycles, with more synchronization points, than other bolts it is

recommended to add a last step before the CE step in the shorter programs. This extra step does not

contain any repair steps or terminate steps. It could be for example a “Run until next step” (NS) or a “Wait”

(W) step. This saves the shorter cycles from getting involved in reject management actions when they

have finished.

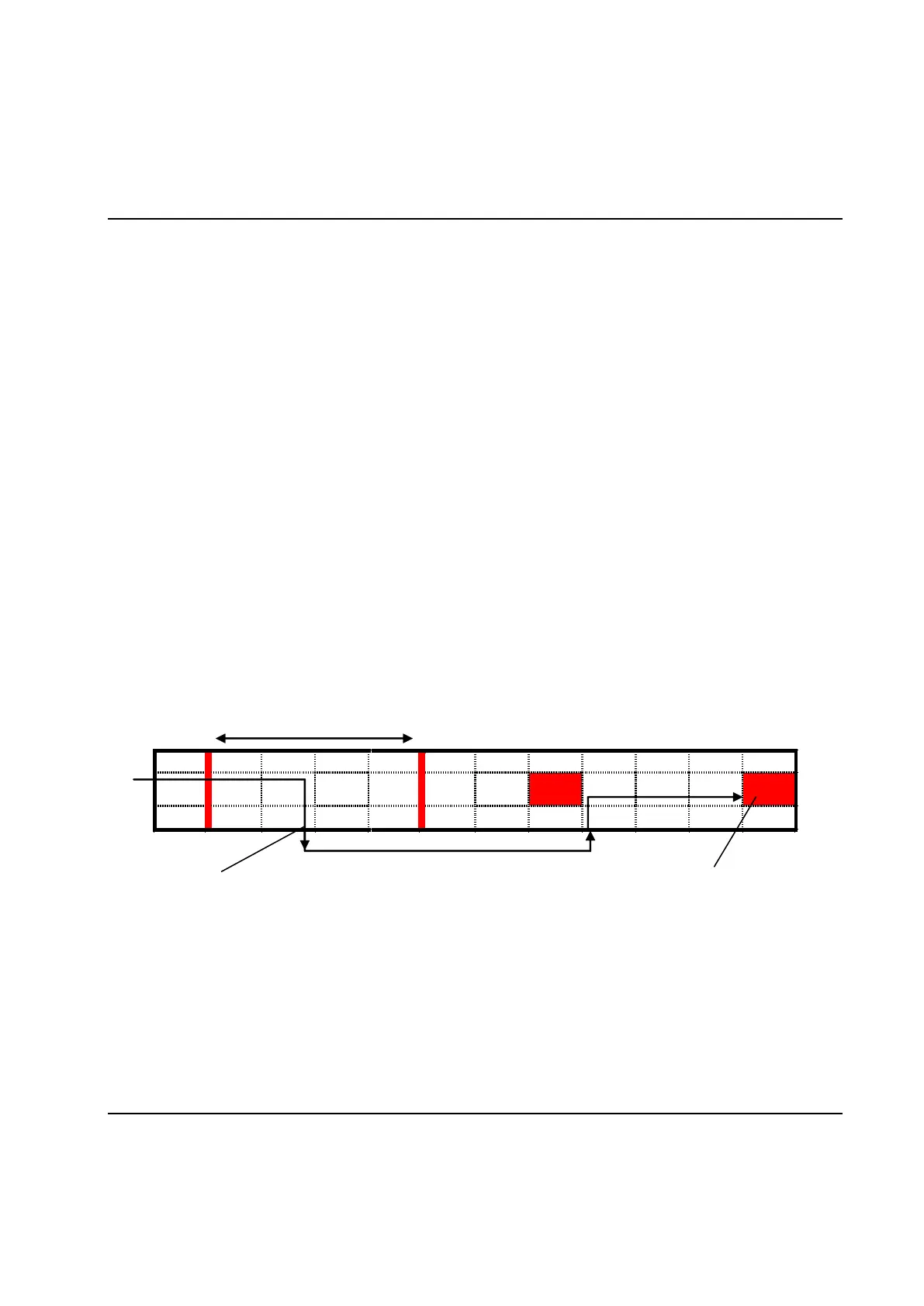

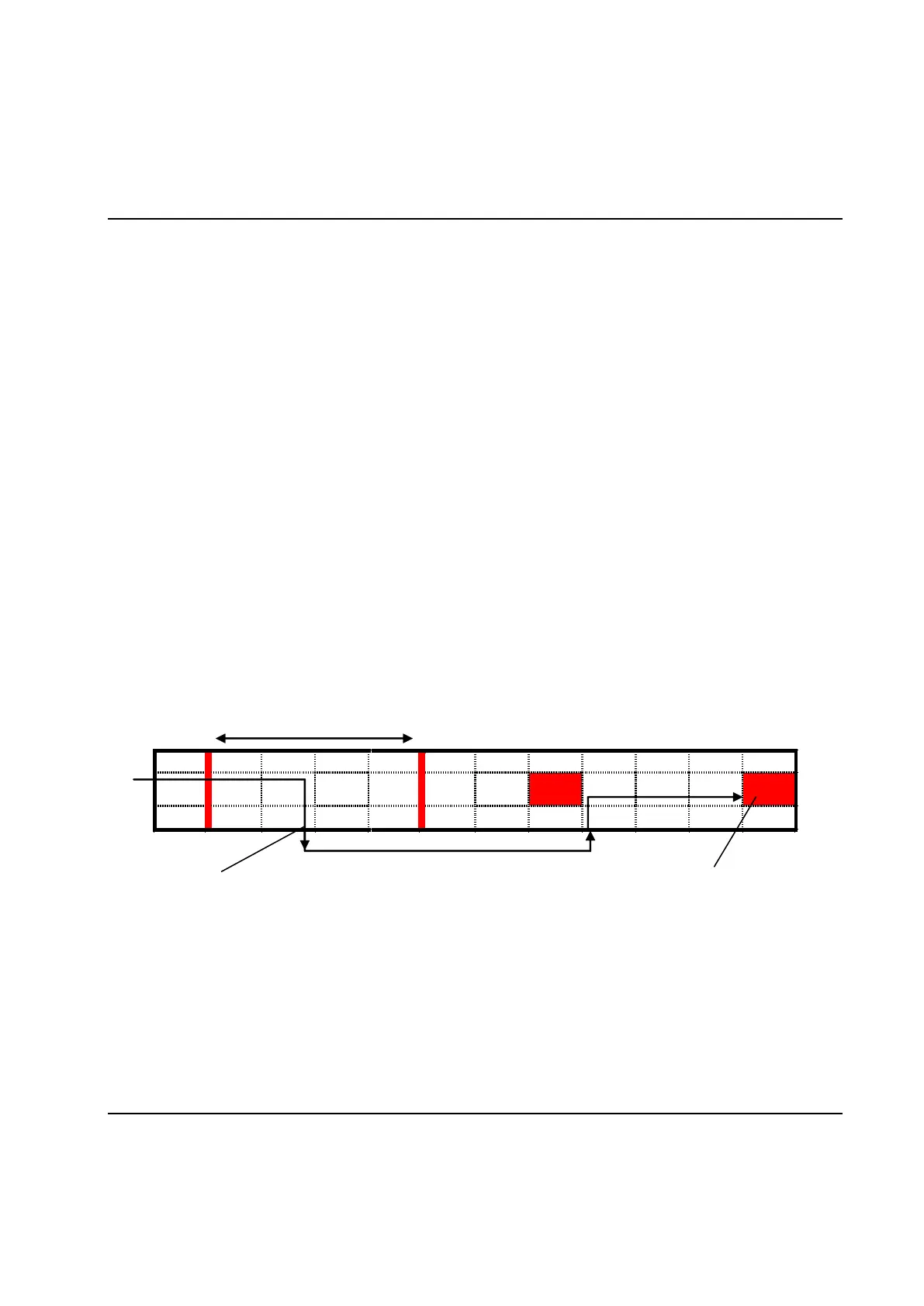

Failing

synchronization

interval

Here the bolt transfer from state RUNNING REPAIR to

RUNNING NORMAL when monitoring is ordered or when next

step is ordered when the bolt has run step 11 and reported CE.

Here the bolt transfer from

state RUNNING NORMAL

to RUNNING REPAIR

Loading...

Loading...