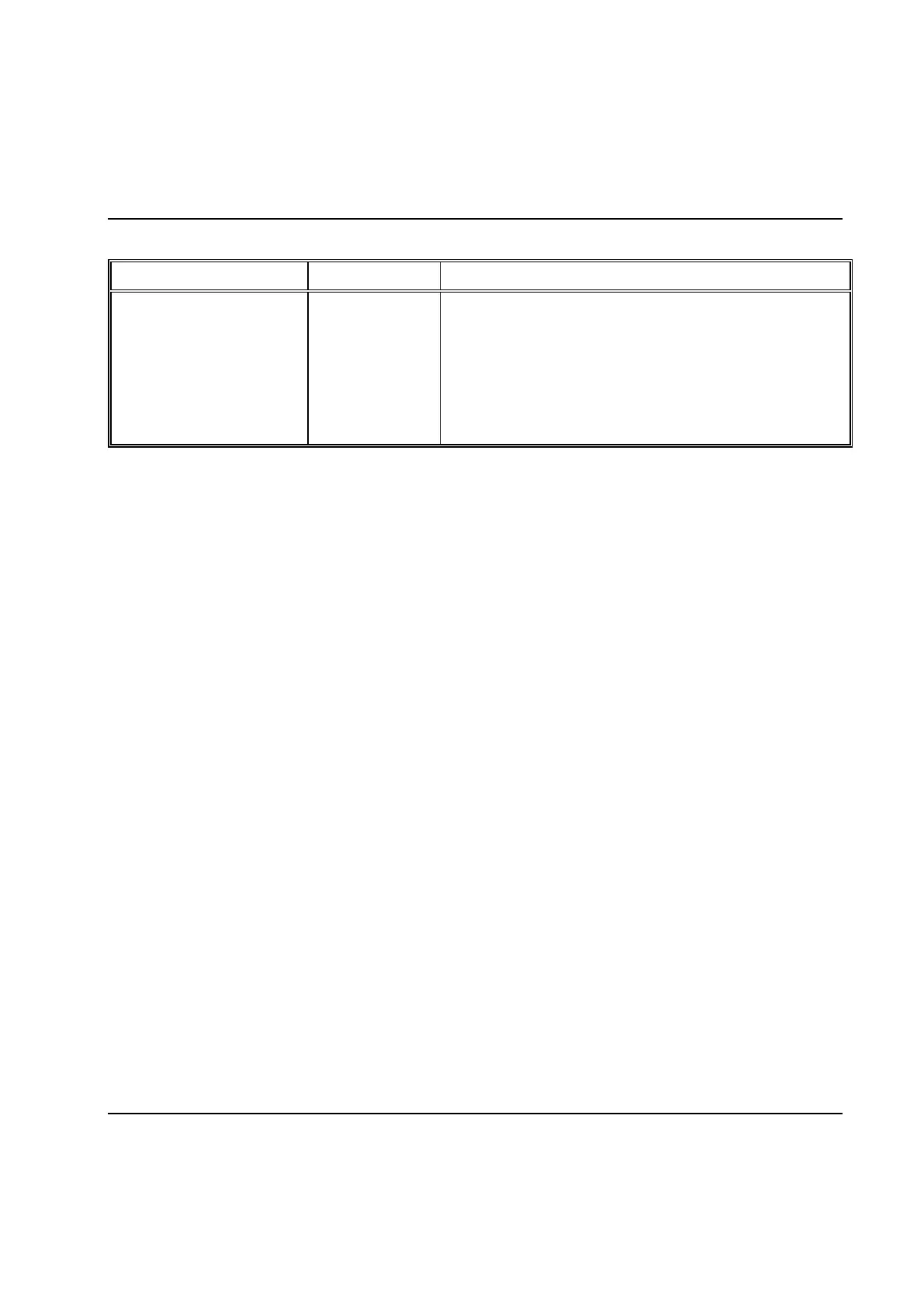

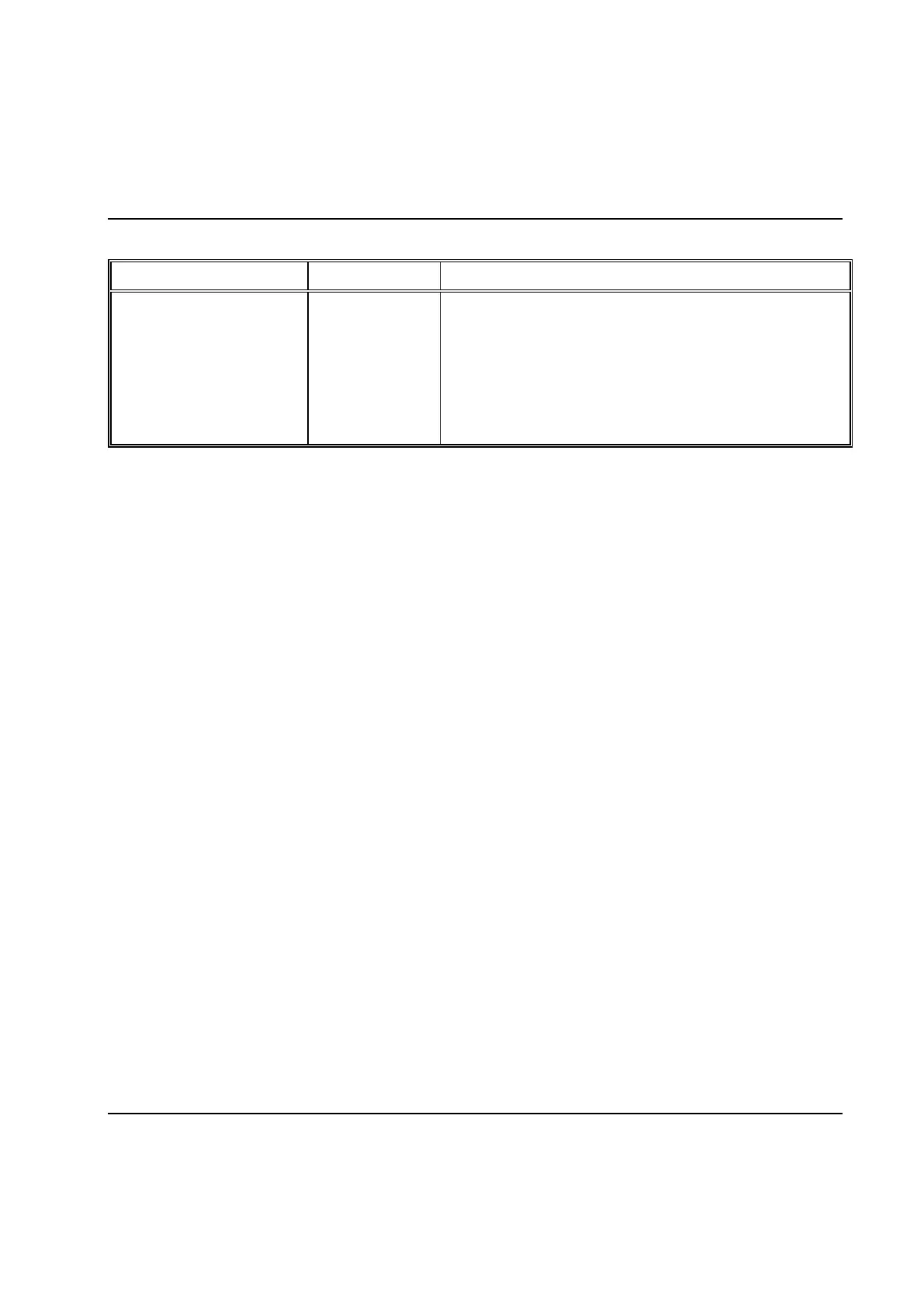

Overall execution status of the DEVCMD command:

0: Idle and OK. Command completed OK.

1: Idle and NOK. Command failed.

2: Busy executing the command.

Note! The operation is not complete until this signal is 0 (or 1 if

it fails). After issuing a DEVCMD command you should wait

one PLC scan before evaluating DEVCMD_STS.

Loading...

Loading...