Peripheral Devices

484 9836 3521 01

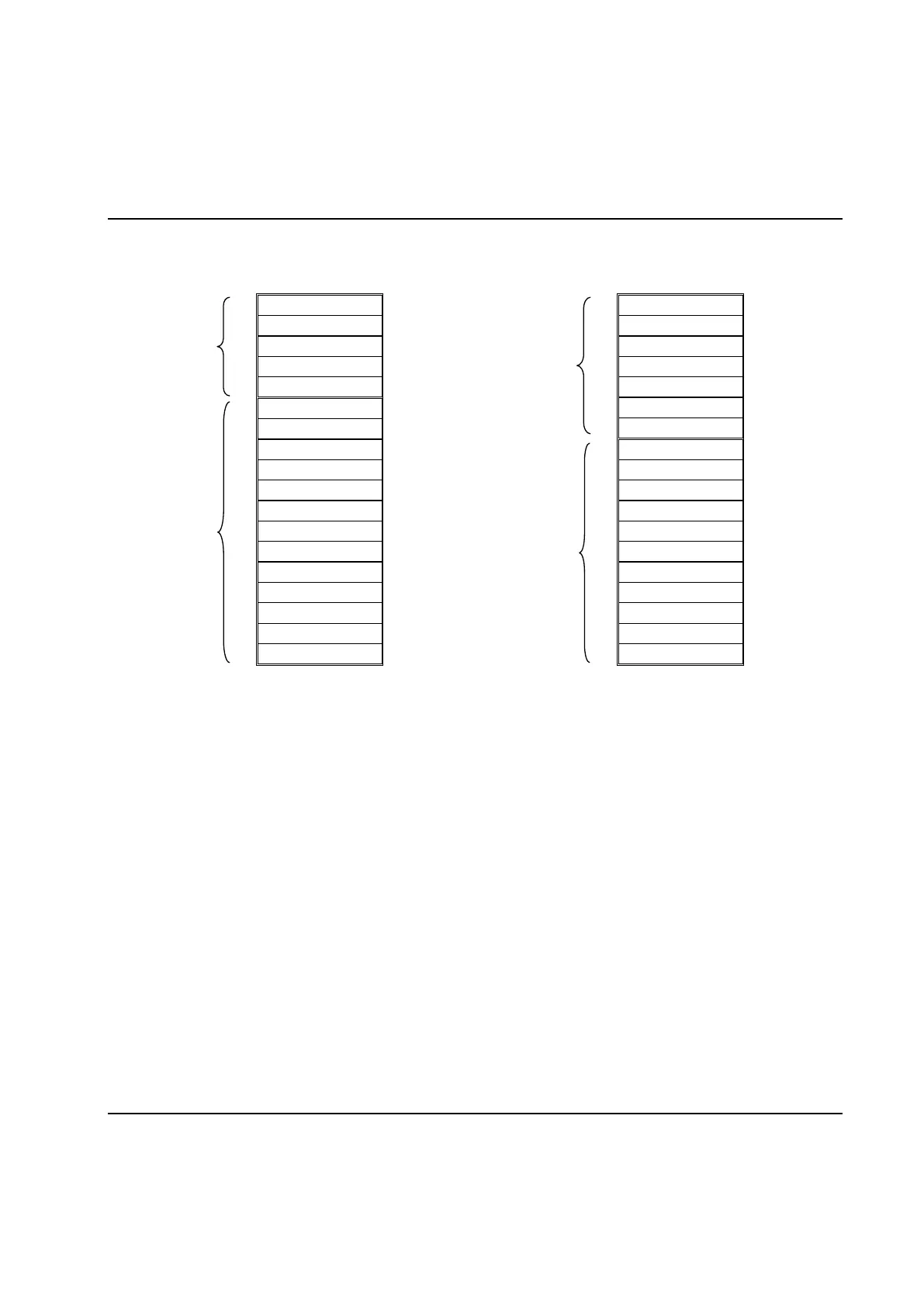

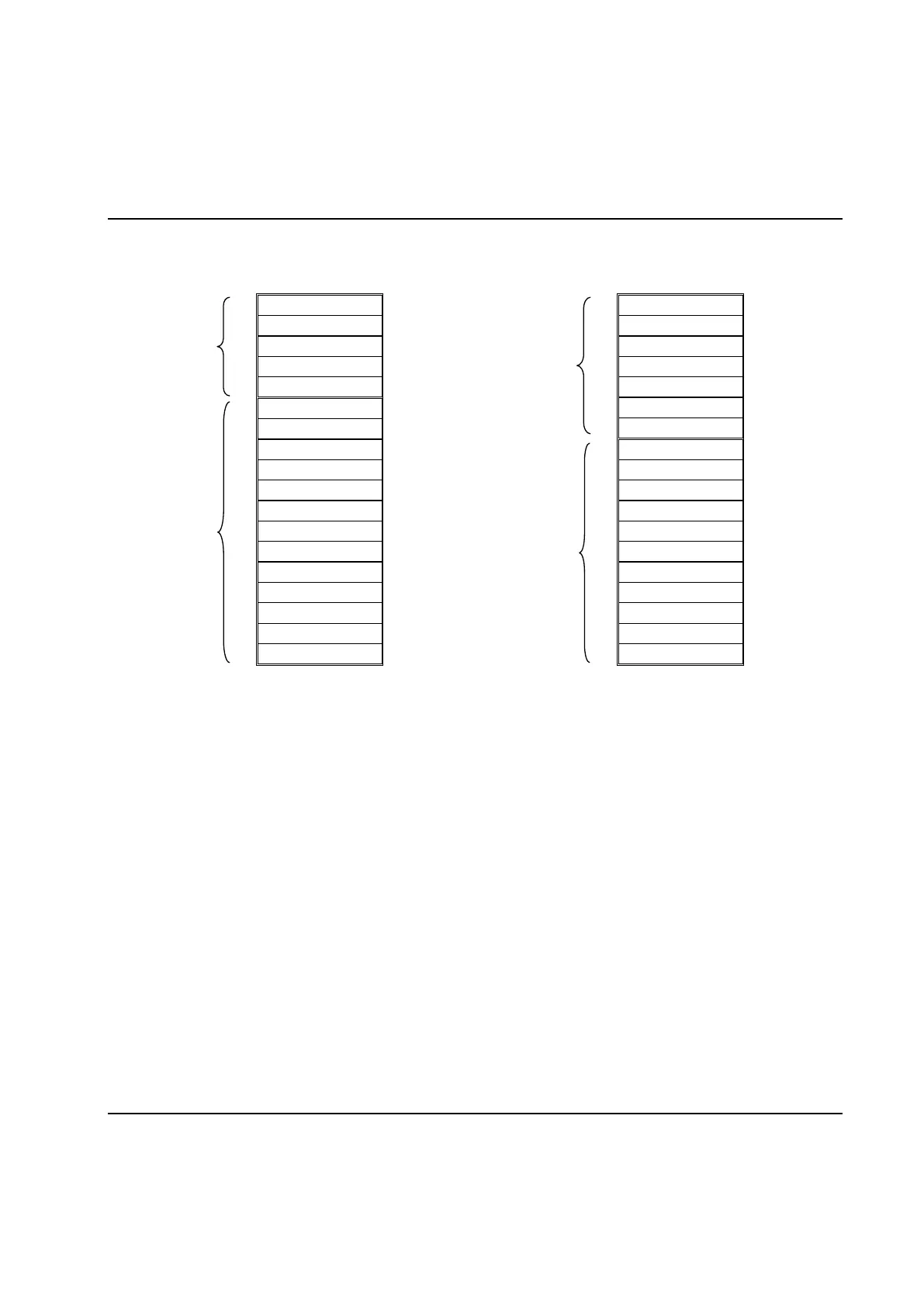

The below picture shows how the input and output areas are divided using the parameters:

Inputs to the

PowerMACS PLC

Size =

Fast bytes In

Used as Process

Data input, e.g.

to request next

cycle data.

Size =

Data bytes In

Outputs from the

PowerMACS PLC

Size =

Fast bytes Out

Used as Process

Data output, e.g.

the requested

cycle data.

Size =

Data bytes Out

Note! You should not configure the respective input and output areas bigger then what really needed. The

reason for this is that all bytes you set up here will be transferred over the fieldbus, regardless if

they are used by the application or not.

If you want to transfer Process data over the fieldbus then you must create a Fieldbus-Reporter. How to

do this, and connect it to your fieldbus device, is described in the New reporter chapter. How to make the

Reporter format the result as you wish is described in chapter: Edit reporter.

Indication of the fieldbus status

When connected to a target system you can study the current status of the module using the

Loading...

Loading...