SmartROC D65 Tier 4 Final 8 Track frames

149

8 Track frames

8.1 Stretching the crawler tracks

!

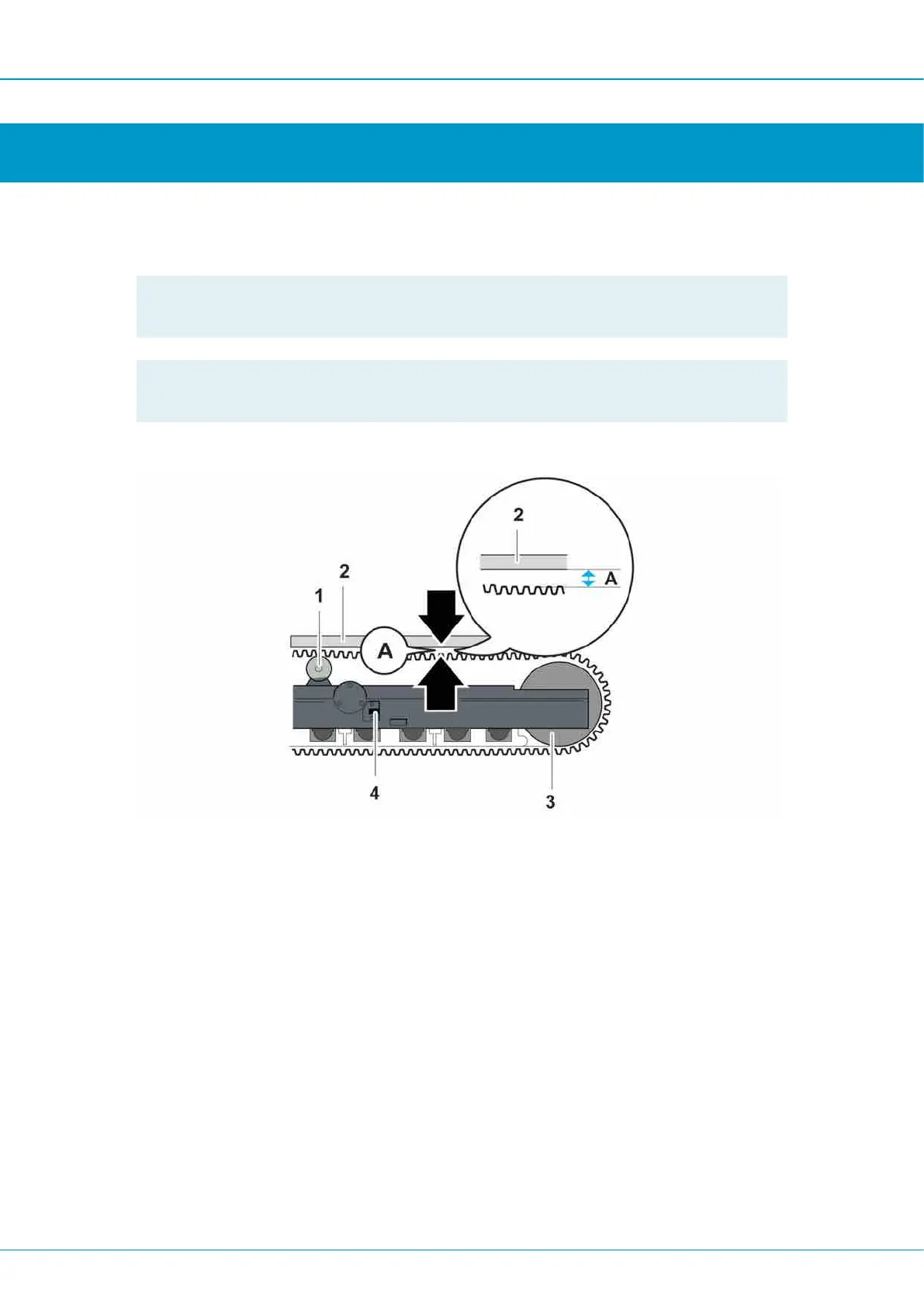

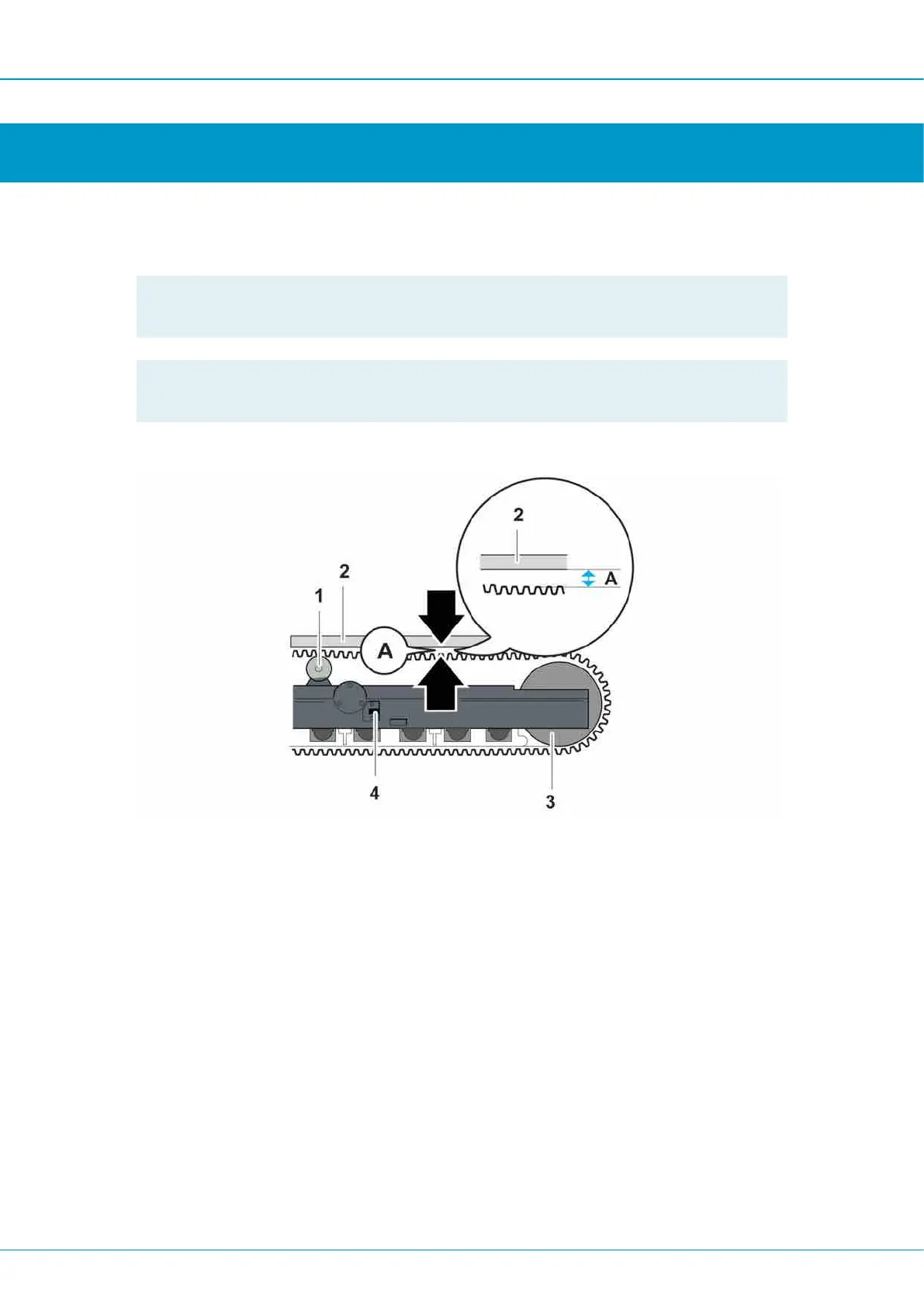

NOTE: The clearance (A, see illustration: Crawler track) between the straightedge and

the crawler track should be between 20 and 30 mm (0.8 and 1.2").

!

NOTE: The grease nipple should not be filled with grease during normal inspection.

Track tension is checked between the front wheel (3) and limberoller (1) when the drill rig is

parked on a level surface with the tracks under normal load.

Crawler tracks

1.

Place a straightedge (2, see illustration: Crawler track) on top of each track.

2.

Pack with grease via the nipple (4) to tension the track.

3.

If necessary, grease can be removed from the tension cylinder by unscrewing the

nipple (4).

Loading...

Loading...