SmartROC D65 Tier 4 Final 14 Options

205

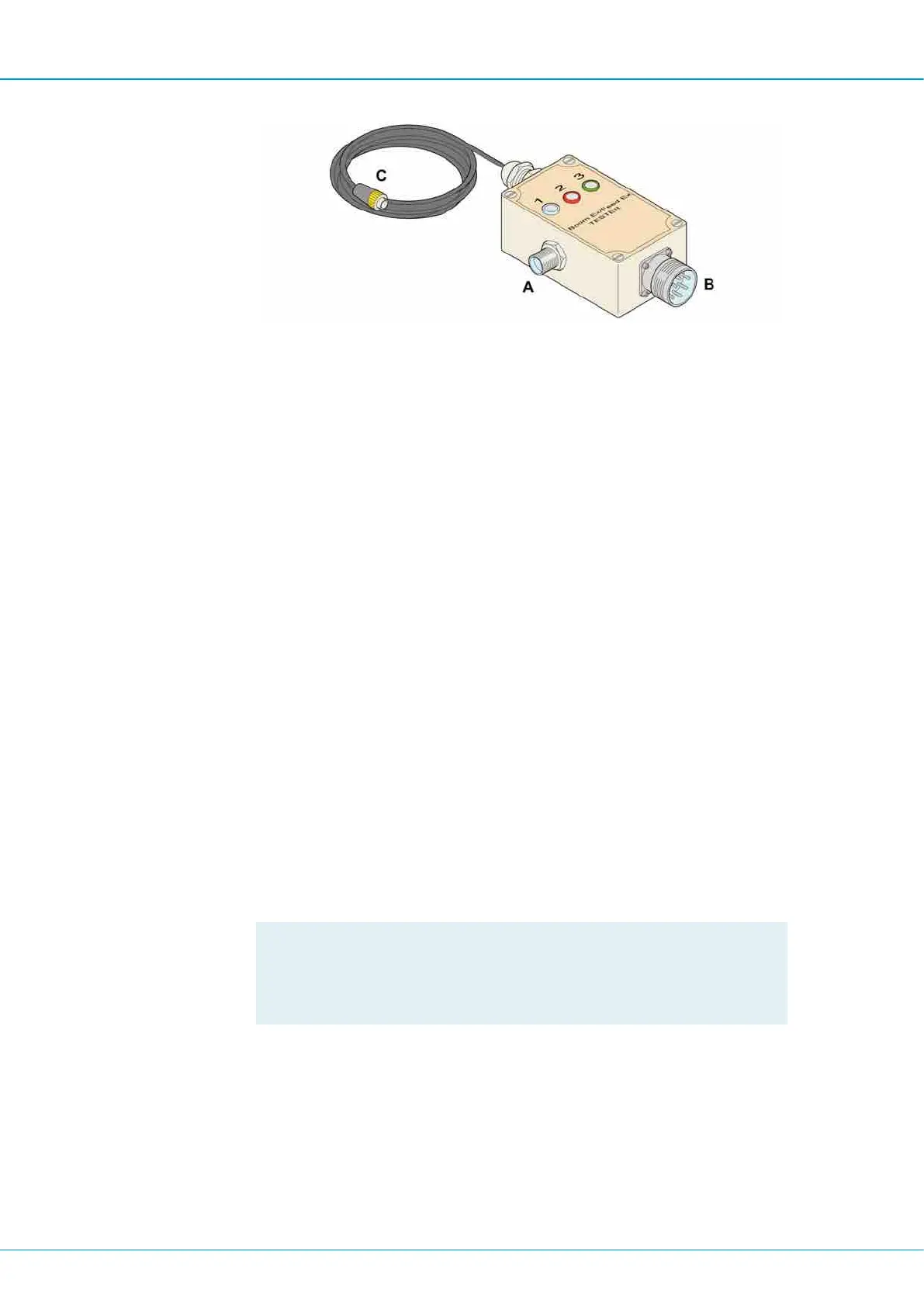

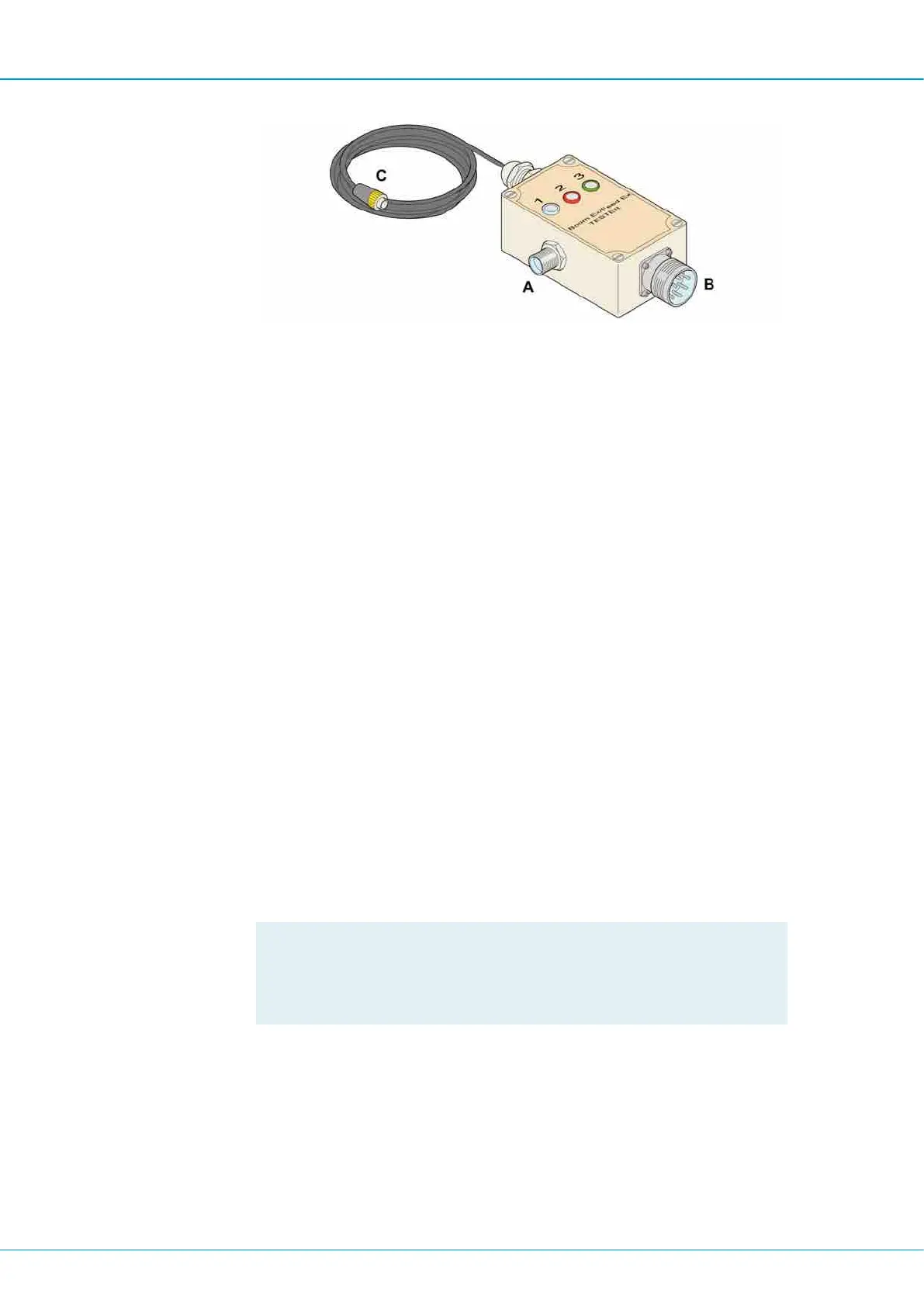

Test box

2.

Connect the multimeter to test box pins 2 and 3.

3.

Set the multimeter to DC voltage (=). It should read 4.5V on connector X11 and 15V

on connector X12.

If the multimeter reading is 0V there may be a fault in the signal cable or resolver

module. Continue fault finding as follows:

a.

Connect the cable (C) on the test box to resolver module input X11 or X12 and

measure between 1 and 2.

b.

Recheck the multimeter reading. If it is 0V, there is a fault on the resolver module

input (X11 or X12).

14.2.5 Replacing the module

1.

Make certain the module has the correct address plug and that the end plug (if any) is

mounted in place.

2.

When any of the application module, I/O or resolver module is replaced, the program

must be read into the system again.

3.

Insert the USB memory stick with the program into the USB port and start the RCS

system.

4.

When the program has been fully loaded, the following will appear on the display:

"Remove card and restart the system!"

5.

Switch off the system - remove the USB memory stick and start the system once

again.

!

NOTE: Make certain that electric power is present at the rig or that

the diesel engine is running before loading the program. Avoid

starting the diesel engine while the program is being loaded. Never

turn off the system while the program is being loaded.

14.3 RC - Reverse Circulation

14.3.1 General

Most maintenance work consists of checking leakage and wear, as well as replacing wear

parts. All parts that come into contact with cuttings are wear parts. The components that

wear the most are the inner tubes and deflectors, the former in particular.

Loading...

Loading...