SmartROC D65 Tier 4 Final 11 Diesel engine

165

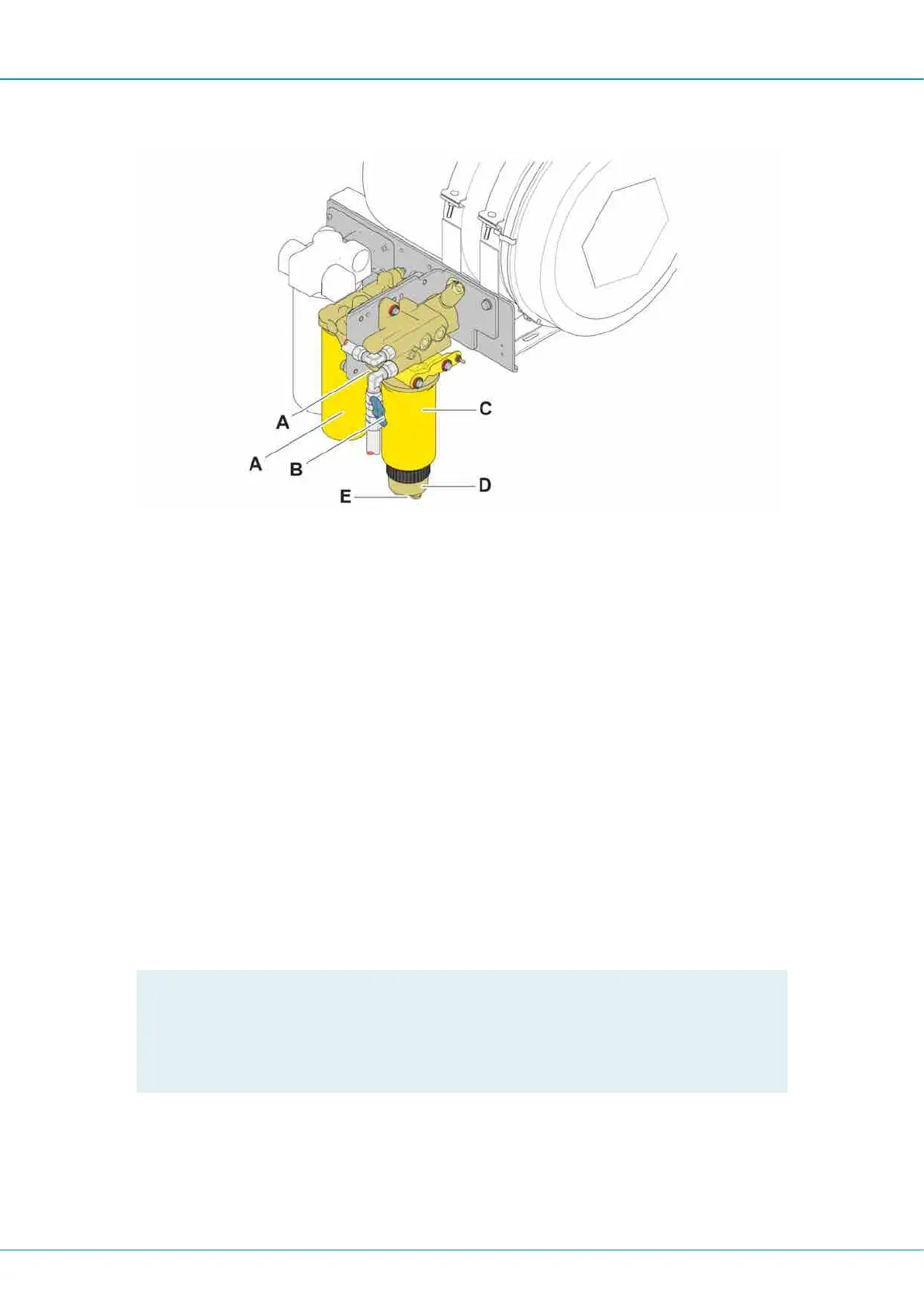

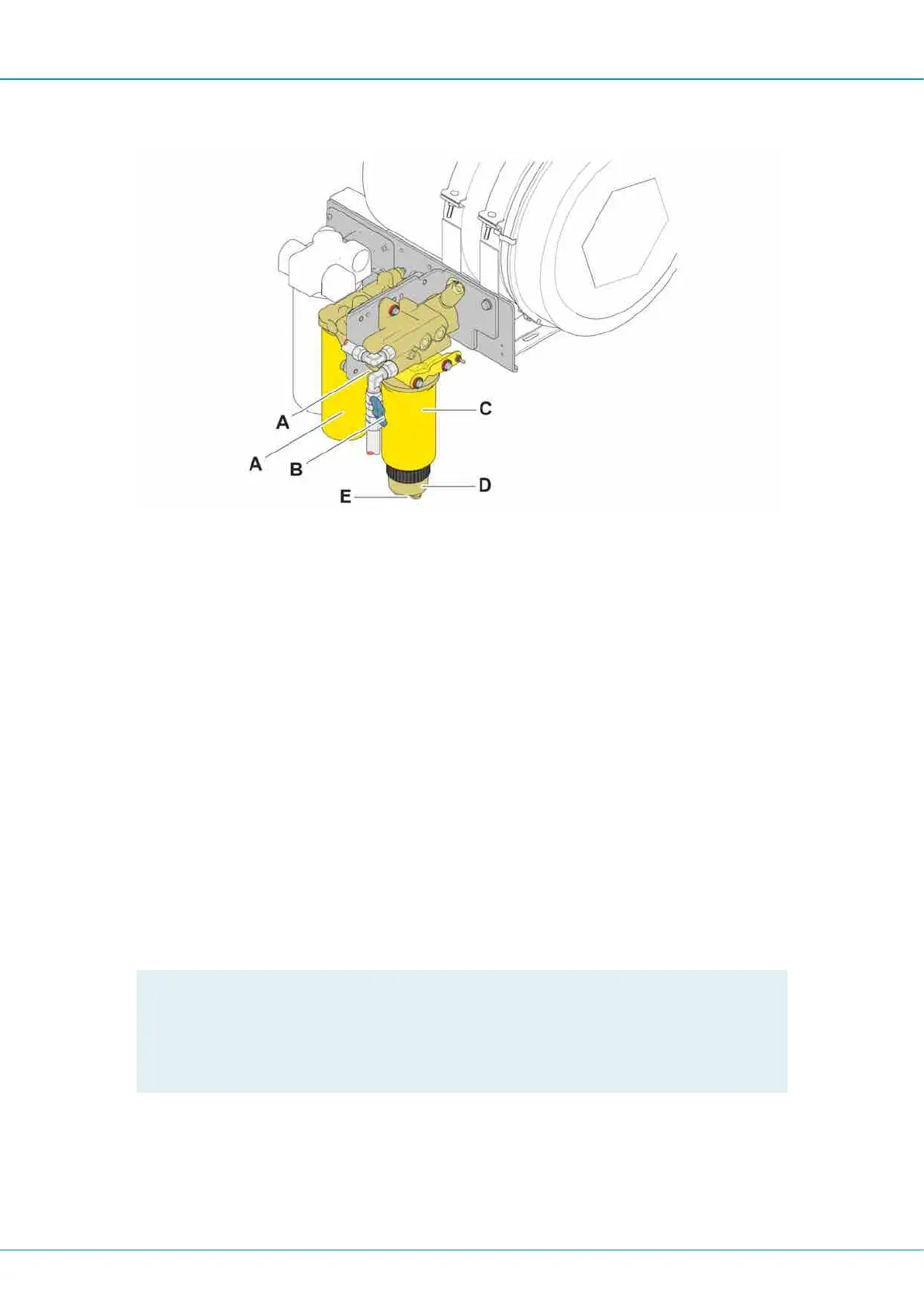

Primary and secondary filters

Primary and secondary filters

Drainage

n Drain the water from the primary filter container daily by closing the fuel cock (B) and

opening the drain cock (E).

Replacing the primary filter

n Remove the filter bowl (D) and clean with pure diesel fuel.

n Remove the fuel filter (C) and then clean the sealing surface on the base of the filter.

Make sure all the remnants of the gasket have been removed.

n Apply pure diesel oil to the new fuel filter gasket.

n Screw on the new fuel filter on the base of the filter until the gasket makes contact with

the filter base. Use the twist marks to aid tightening. Tighten the filter a further three

quarters of a turn by hand. Do not tighten the filter too hard.

n Screw the clean filter bowl (D) back in place.

Replacing the secondary filter

n Close the fuel cock for the primary filter (B).

n Slacken off the secondary filters (A) using a suitable tool and remove them.

n Collect any residual fuel.

n Clean the filter holders seal surfaces of dirt.

n Apply a thin layer of oil to the new fuel filter rubber seals.

!

NOTE: The primary filter/water separator can be filled with fuel in advance so that the

engine does not run unevenly or stop due to air bubbles. Do not fill the secondary fuel

filter with fuel before installation. The fuel would not then be filtered and could be con-

taminated. Contaminated fuel increases the wear on the components of the fuel sys-

tem.

Filter for DEF tank

Changing the DEF tank filter:

n See separate instructions from diesel engine.

Loading...

Loading...