SmartROC D65 Tier 4 Final 12 Compressor and air system

178

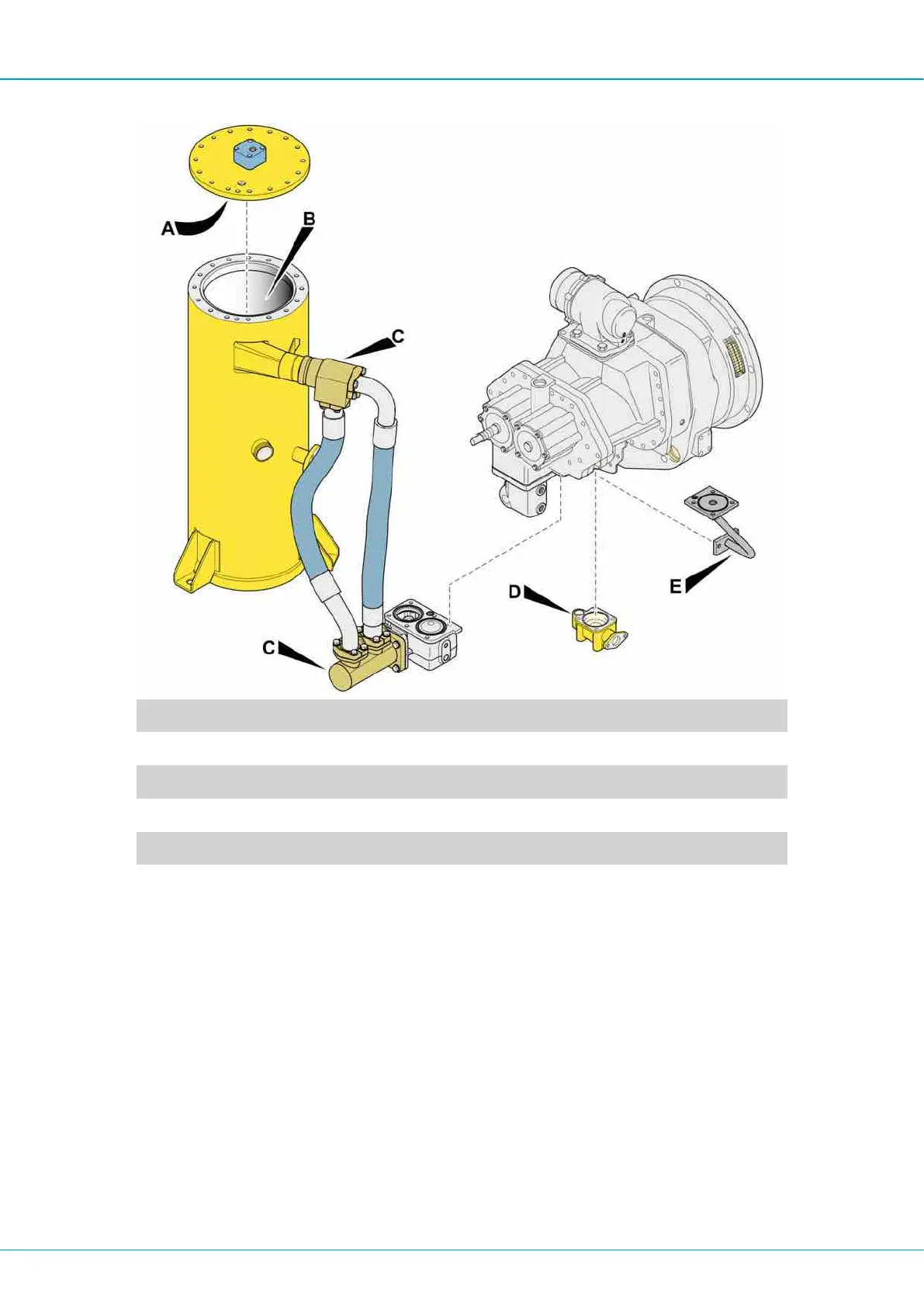

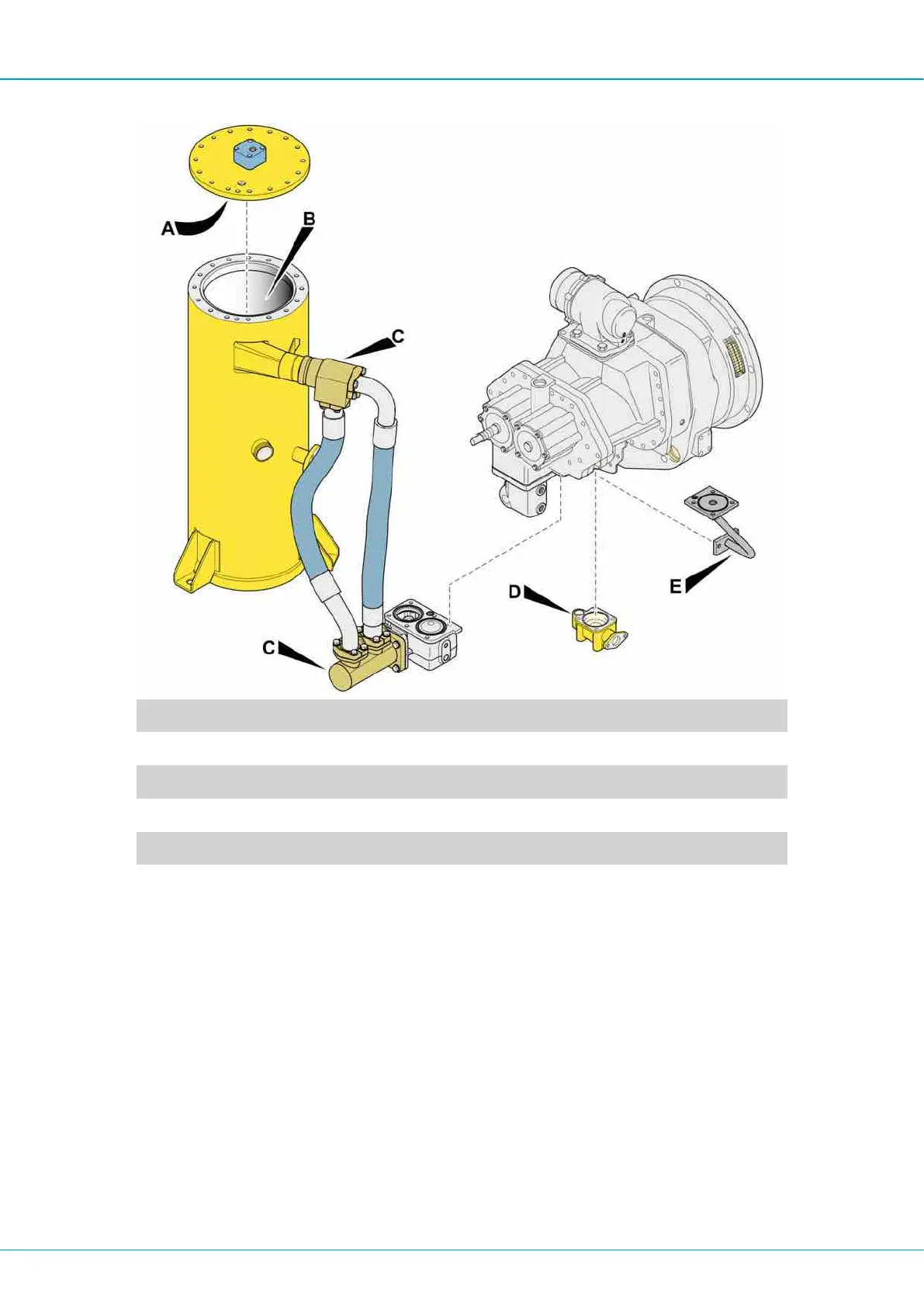

A Underside of reservoir cover plate

B Inside of reservoir

C Hose connections

D Oil stop valve

E Pipe

Procedure for compressor flushing

1.

First of all, the system must be drained thoroughly when the oil is hot so that as little

oil as possible is left in the system, especially in inaccessible areas. If possible the oil

system must also be pressure washed so that the remaining oil will be blown out. See

step 1 and 2 under the heading "Change of oil and oil filter" for detailed description.

2.

Remove the oil filters (a).

3.

Open the cover plate on the air receiver and remove the oil separator element.

4.

Check the inside of the oil reservoir. If sediments are detected, the parts (A-E) must

be thoroughly cleaned before the process is completed. Contact Atlas Copco's ser-

vice department.

5.

Insert a new oil separator element, screw on the new oil filter and close the valve in

accordance with the instructions under the heading "Changing oil and oil filter".

Loading...

Loading...