5-5

Calibrate to check that the current CO

2

flow rate is less than 10 ml/min. If the alarm message remains on the

screen, it indicates that the module does not leak.

Microstream: After 3 seconds, the alarm message "CO

2

Purging" is displayed on the screen. Block the gas

inlet for another 30 seconds. If the alarm message "

CO

2

Airway Occluded" is displayed, it indicates that the

module does not leak.

5.2.3.2 Accuracy Test

Tools required:

Steel gas cylinder with CO

2

(concentration range 3%~7%) and balance gas N

2

T-shape connector

Air tubing

Flowmeter

1. Connect the module and the monitor.

2. Wait until the CO

2

module warmup finishes. Check the airway for leakage and perform a leakage test as well to

make sure that the airway has no leakage.

3. Select Main Menu → System → Maintenance → Module → CO

2

→ Calibrate.

4. Connect the test system as follows:

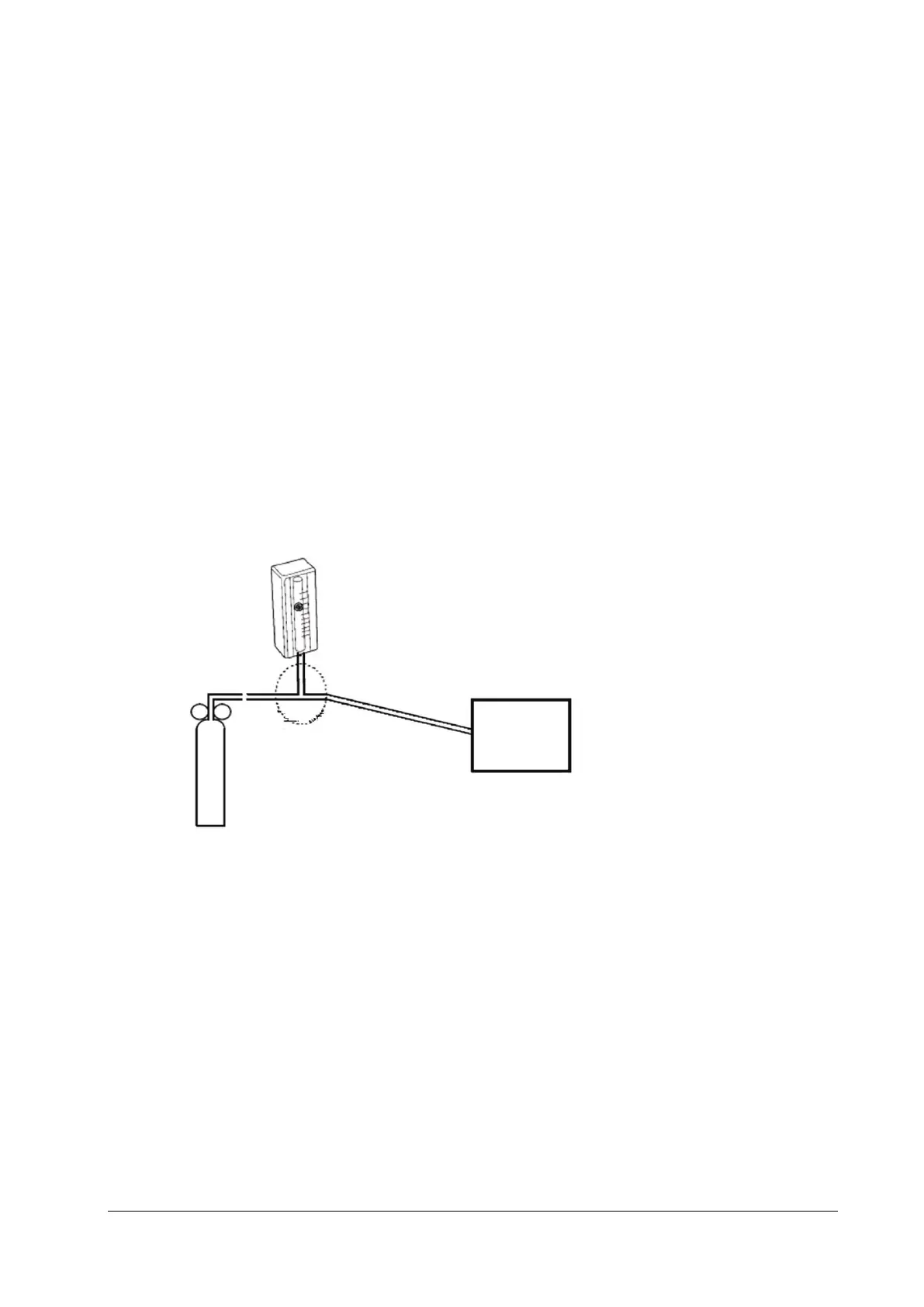

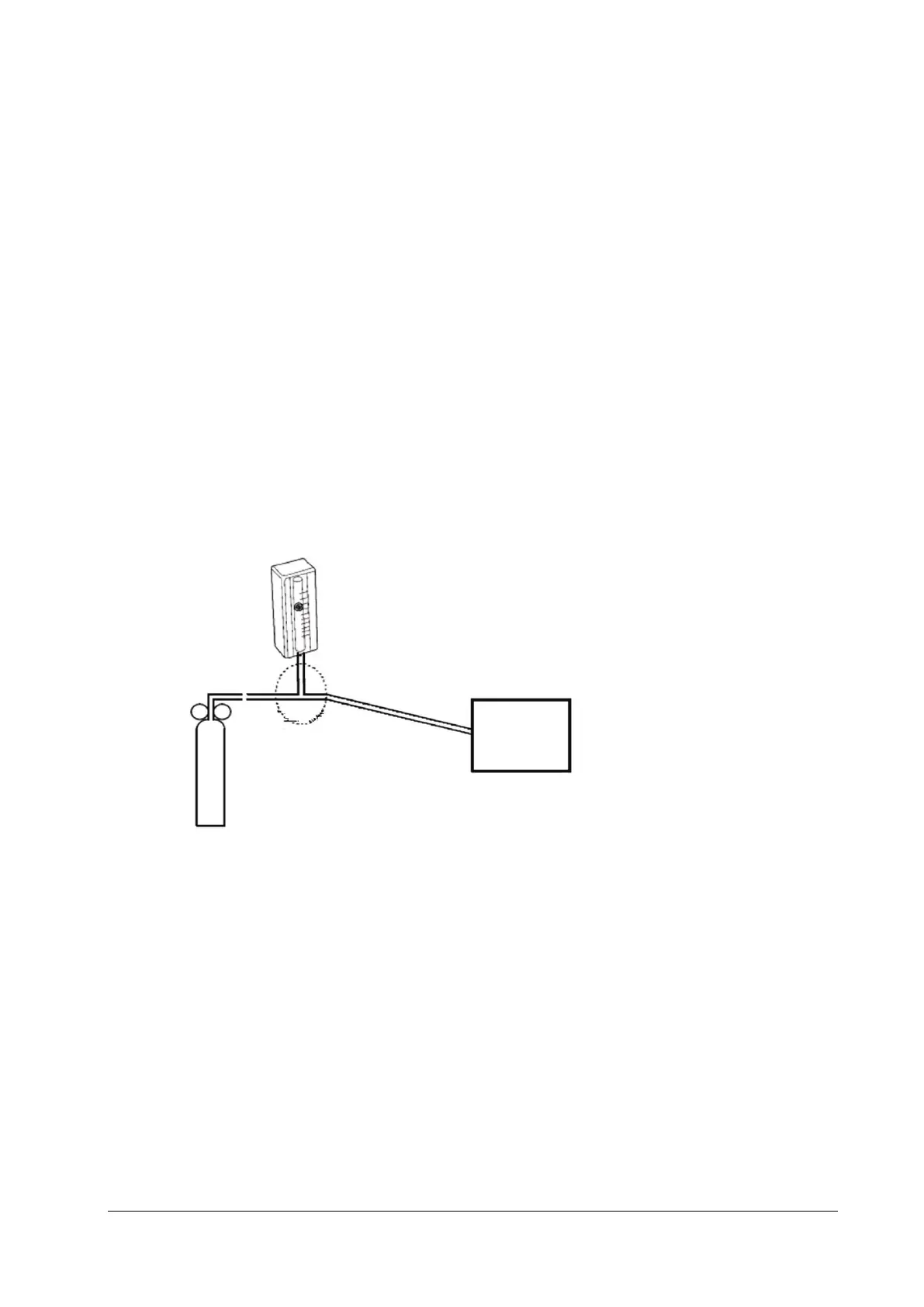

Relief

valve

T-shape connector

Gas

cylinder

Tubing

Monitor

Flowmeter

5. Open the relief valve and adjust it until the flowmeter has a stable reading between 10 ml/min and 50 ml/min.

6. Check the real-time CO

2

value in the Calibrate menu and make sure the variation from the actual concentration is

within±0.3%.

5.2.3.3 Module Calibration

Tools required:

Steel gas cylinder with 6±0.05% CO

2

and balance gas N

2

T-shape connector

Air tubing

1. Make sure that the sidestream or microstream CO

2

module has been warmed up or started up.

2. Check the airway for leakage and perform a leakage test as well to make sure that the airway has no leakage.

Loading...

Loading...