5-11

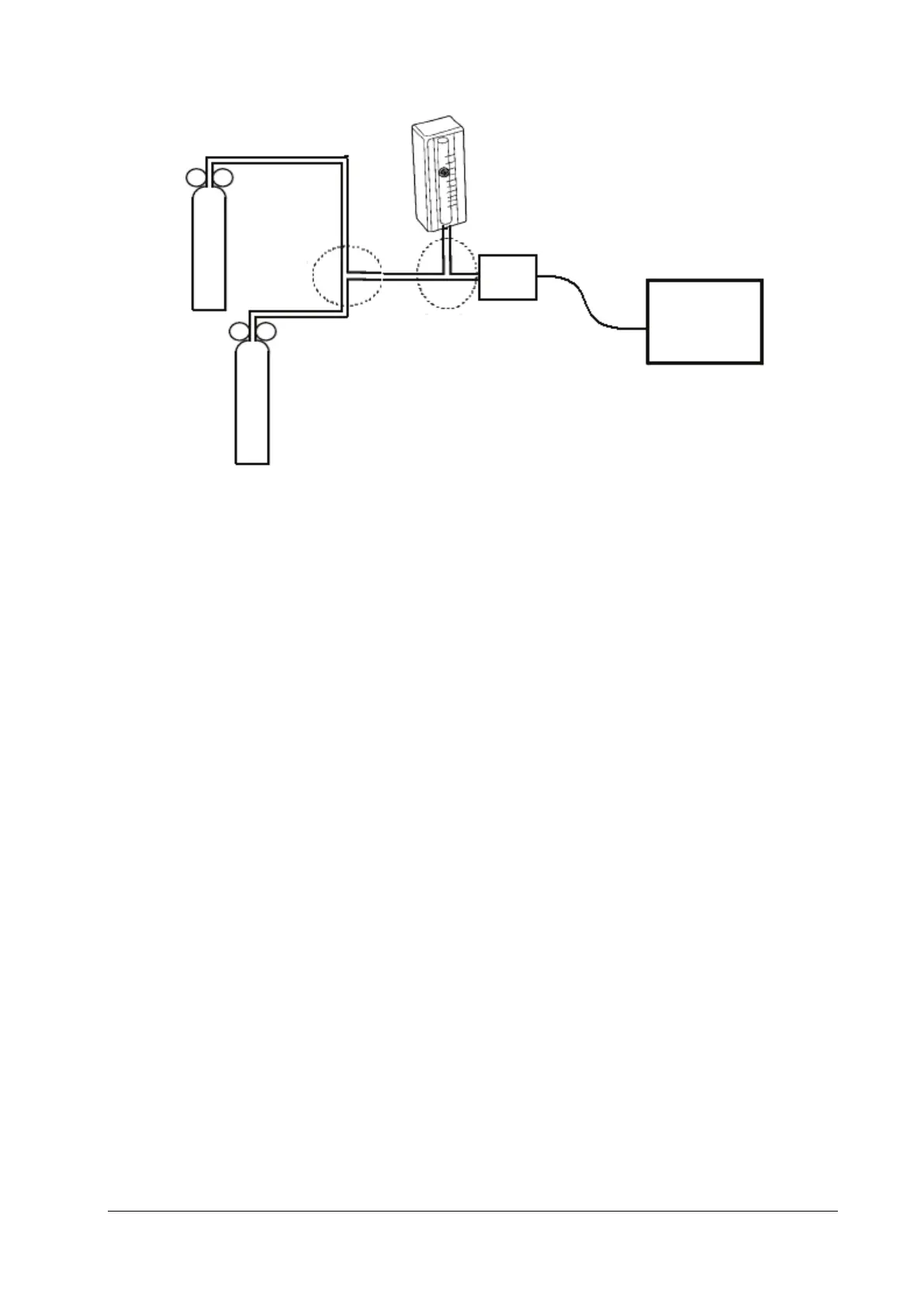

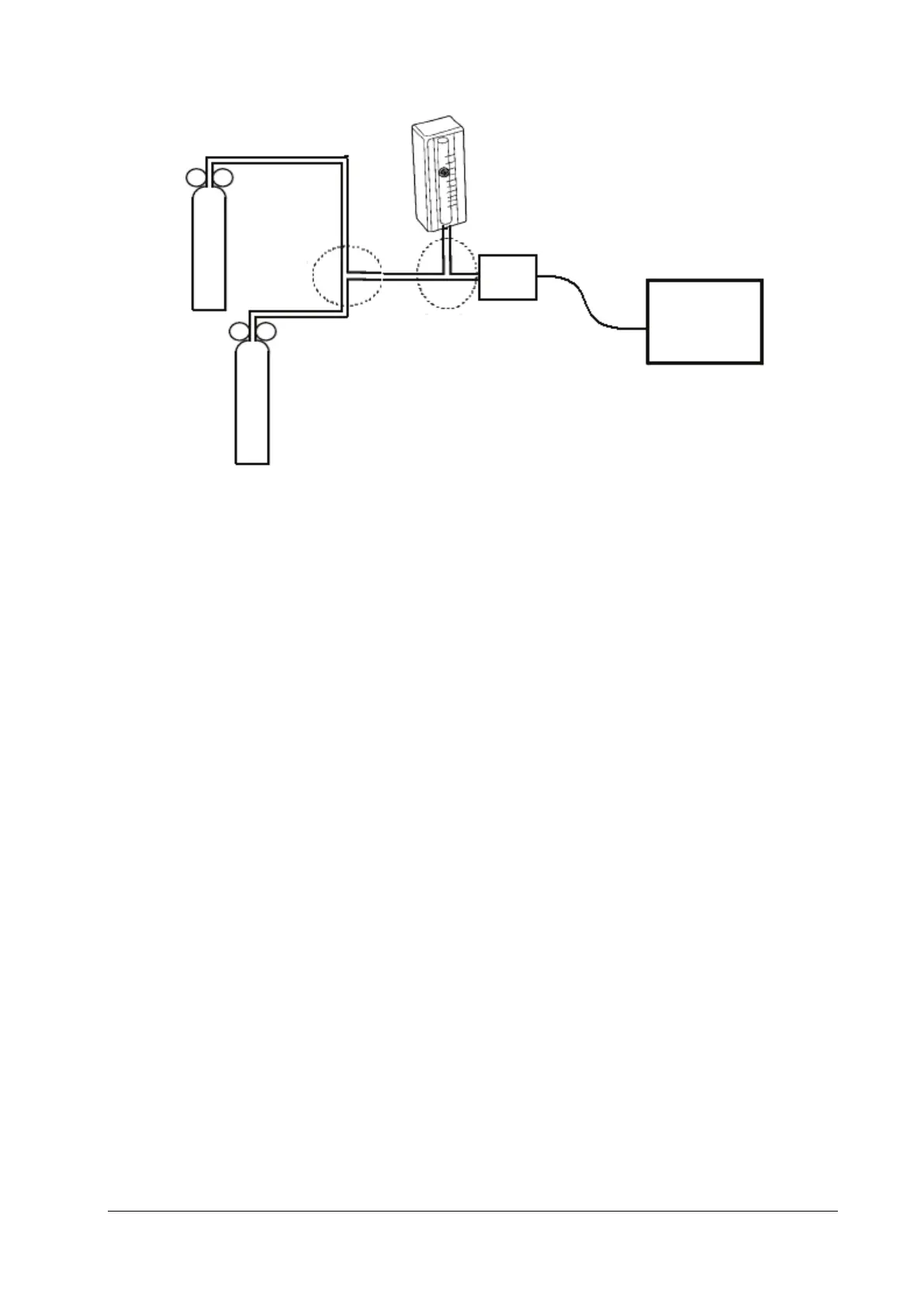

6. Separately turn on the relief valves of N

2

gas cylinder and CO

2

cylinder to ensure that only one gas cylinder is

connected to the T-shape connector at a time.

7. Separately adjust the relief valves to ensure a stable flow by maintaining the reading on the flowmeter at a value

between 2 L/min and 5 L/min.

8. Switch between the two cylinders connected to the T-shape connectors at intervals of 6–10s and check if the

displayed CO

2

value is within 45±2 mmHg.

5.4.8 Sidestream and Microstream CO

2

Modules Tests and Calibration

Refer to section 5.2.3 Sidestream and Microstream CO2 Modules Tests and Calibration.

5.4.9 PiCCO Test

5.4.9.1 Performance Test

Tools required:

Patient simulator: Medsim300B

PiCCO IBP test cable (P/N: 040-001300-00)

1. Connect the patient simulator, the PiCCO IBP test cable, and the PiCCO module.

2. Set the patient simulator to output 0 mmHg to the pArt channel and the pCVP channel.

3. In the pArt Setup menu, select pArt

Zero >>→Zero.

4. In the pCVP Setup menu, select pCVPZero >>→Zero.

5. Set the patient simulator to output static pressure 200 mmHg to the pArt channel and 20 mmHg to the pCVP

channel.

6. Check that the pArt value displayed on the monitor is within 200±4 mmHg, and pCVP value within 20±1 mmHg.

7. If the pArt error is beyond ±4 mmHg or pCVP error beyond ±1 mmHg, calibrate the PiCCO module. If the module

was calibrated with a dedicated reusable IBP sensor, check the calibration together with this IBP sensor.

Monitor

CO

2

gas

cylinder

Flowmeter

Relief

valve

Mainstream sensor

Relief valve

N2 gas cylinder

T-shape

connector

T-shape

connector

Loading...

Loading...