Appendix

13.2 Manual test procedures

5284 / 08/2023 en BENNING ST 755+ / ST 760+ 107

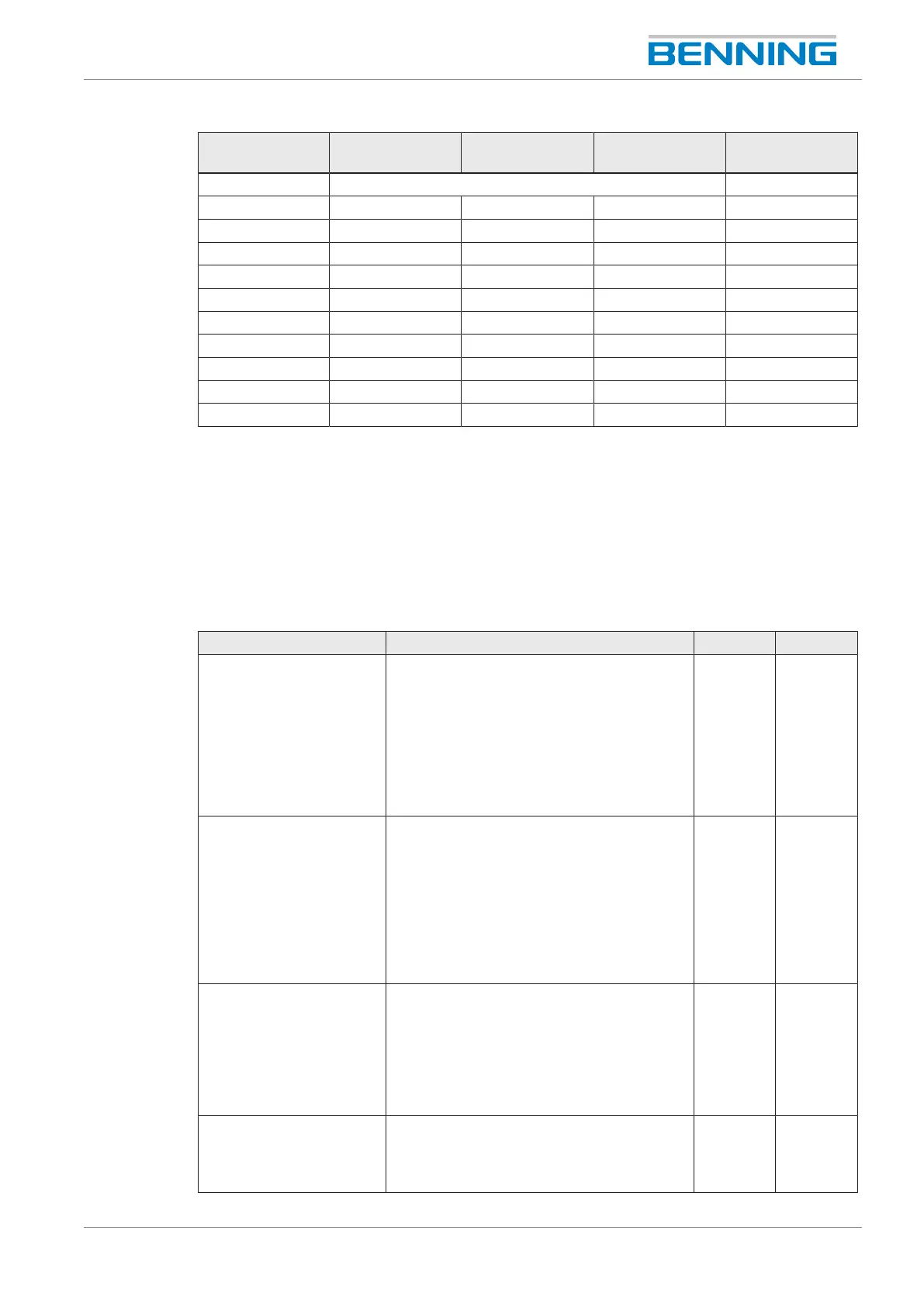

Test/

test no.

1 2 3 1

Protection class ClassI ClassII

Visual inspection X X X X

Connection test X X X X

R

PE

600mA X X X -

R

Insu-1

/ R

Insu‑IN

X X X X

R

Insu-2

X X X X

R

Insu-3

X X X X

I

Cont

X X X -

I

Contweld.

X X X X

Funct. X X X X

U

aweld.

X X X X

Table40: Overview of test procedures according to EN60974-4 (VDE0544‑4) for ClassI (1to 3)/

ClassII(1)

13.2 Manual test procedures

13.2.1 Manual test procedures according to EN50678

(VDE0701) and EN50699 (VDE0702)

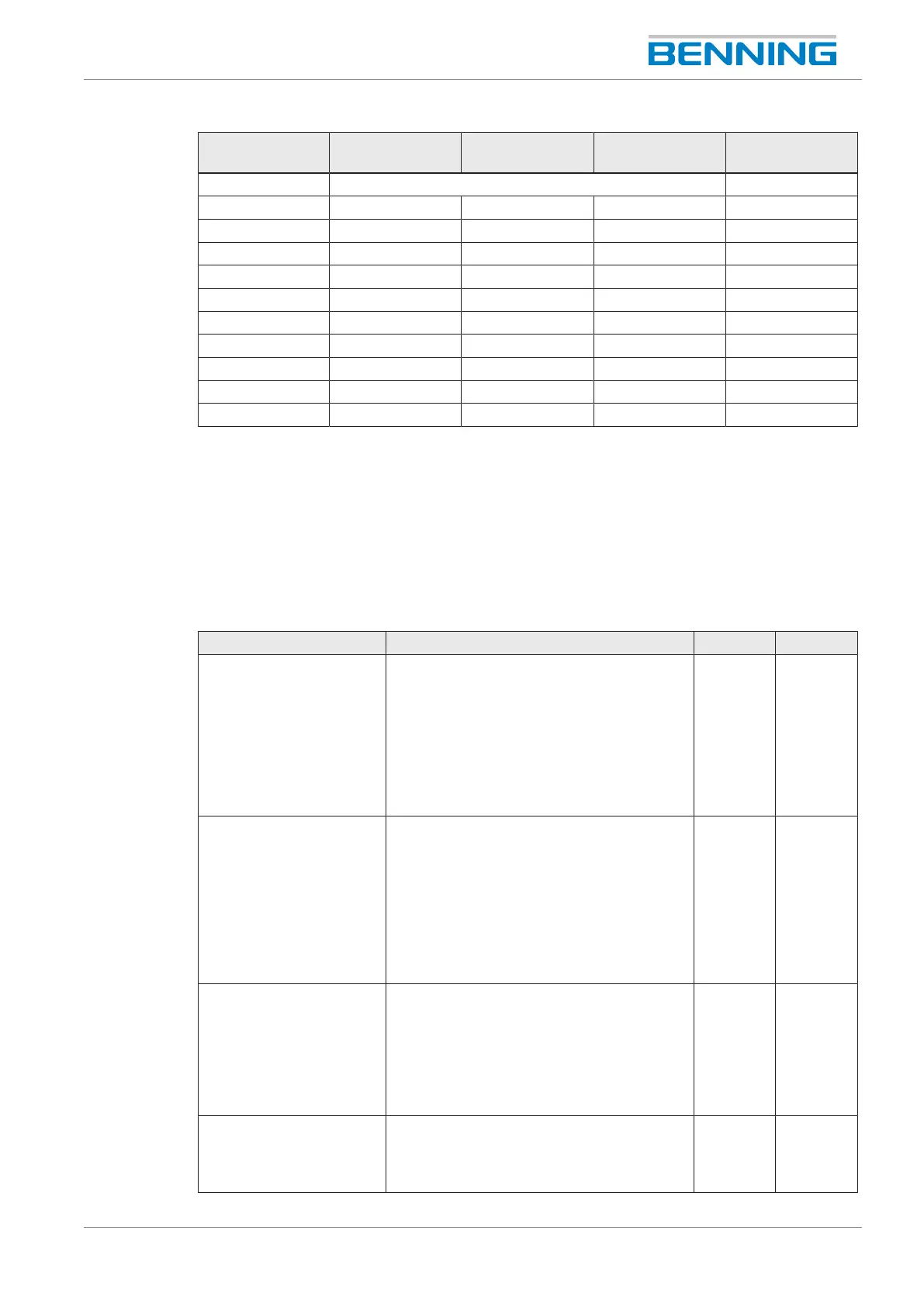

Test ClassI ClassII ClassIII

Visual inspection for

visible defects:

• Connecting cables/

plug connections

• Housing, strain relief,

protection against

bending and kinking

etc.

X X X

Testing the protective

conductor with regard to:

Continuity between the

earthing contact of the

mains plug and accessible

conductive parts of the

device/ the device

connection

For cables with a rated current of ≤16.0A:

For cables up to 5m: ≤0.3Ω

For additional meters (up to 7.5m each),

0.1Ω is added to the limit up to a maximum

value of 1.0Ω.

For cables with higher rated currents, the

calculated ohmic resistance value shall

apply.

- -

Measuring the insulating

resistance

Generally: ≥1.0MΩ

For proving safe isolation: ≥2.0MΩ

For devices with heating elements:

≥0.3MΩ

For devices with heating elements and a

power of >3.5kW: ≥0.3MΩ

≥2MΩ ≥0.25MΩ

Measuring the protective

conductor current

≤3.5mA on conductive components with

PEconnection: 1mA/kW to max.10mA

for devices with heating elements and a

total power of more than 3.5kW

- -

Loading...

Loading...