FrameMaker Ver5.5E(PC) Di152/Di183 MECHANICAL/ELECTRICAL

01.09.05

M-45

19-3. Fusing Temperature Control

• The Fusing Roller Heater Lamp is turned ON and OFF to keep a set temperature on the

surface of the Fusing Roller.

• The Fusing Roller surface temperature is detected by using a thermistor that translates

the temperature to a corresponding electrical signal.

• If the Fusing Roller temperature becomes excessively high, the Fusing Roller Heater

Lamp is shut down.

19-4. CPM Control

• If paper of a small size (width of 250 mm or less) or thick paper is used to run a multi-

copy cycle, the temperature on the edges of the Fusing Rollers tends to run high, mean-

ing that the temperature of the Fusing Rollers varies among different spots of the rollers.

• When the cumulative number of copies made through continuous copy cycles* exceeds

30, the paper take-up interval is made longer, thereby allowing the temperatures of the

Fusing Rollers at different spots to be uniform.

✽ Continuous copy cycle: Continuous copy cycles run with an interval of 2 min. or less

between cycles.

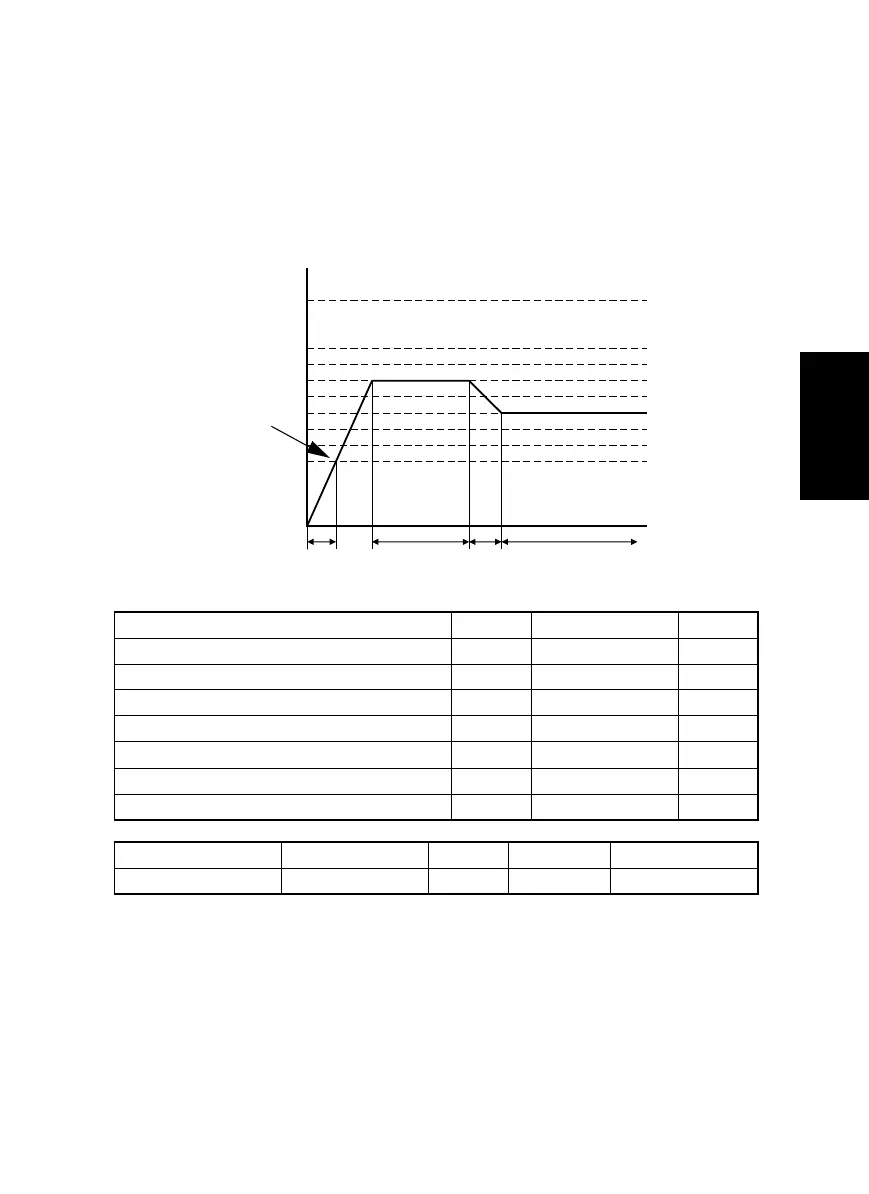

Machine Condition or Paper Type Mode 1 Mode 2 Mode 3

Standby 180 °C180 °C

→ 170 °C170 °C

Plain paper (width 251 mm or more) 190 °C190 °C

→ 170 °C170 °C

Plain paper (width 250 mm or less) 160 °C160 °C160 °C

Thick paper (width 251 mm or more) 210 °C210 °C

→ 190 °C190 °C

Thick paper (width 250 mm or less) 200 °C200 °C

→ 190 °C190 °C

OHP transparencies (width 251 mm or more) 180 °C180 °C

→ 165 °C165 °C

OHP transparencies (width 250 mm or less) 155 °C155 °C155 °C

Elevtrical Component Control Signal ON OFF Wiring Diagram

H1 PWB-A PJ10A-7 L H 1-D

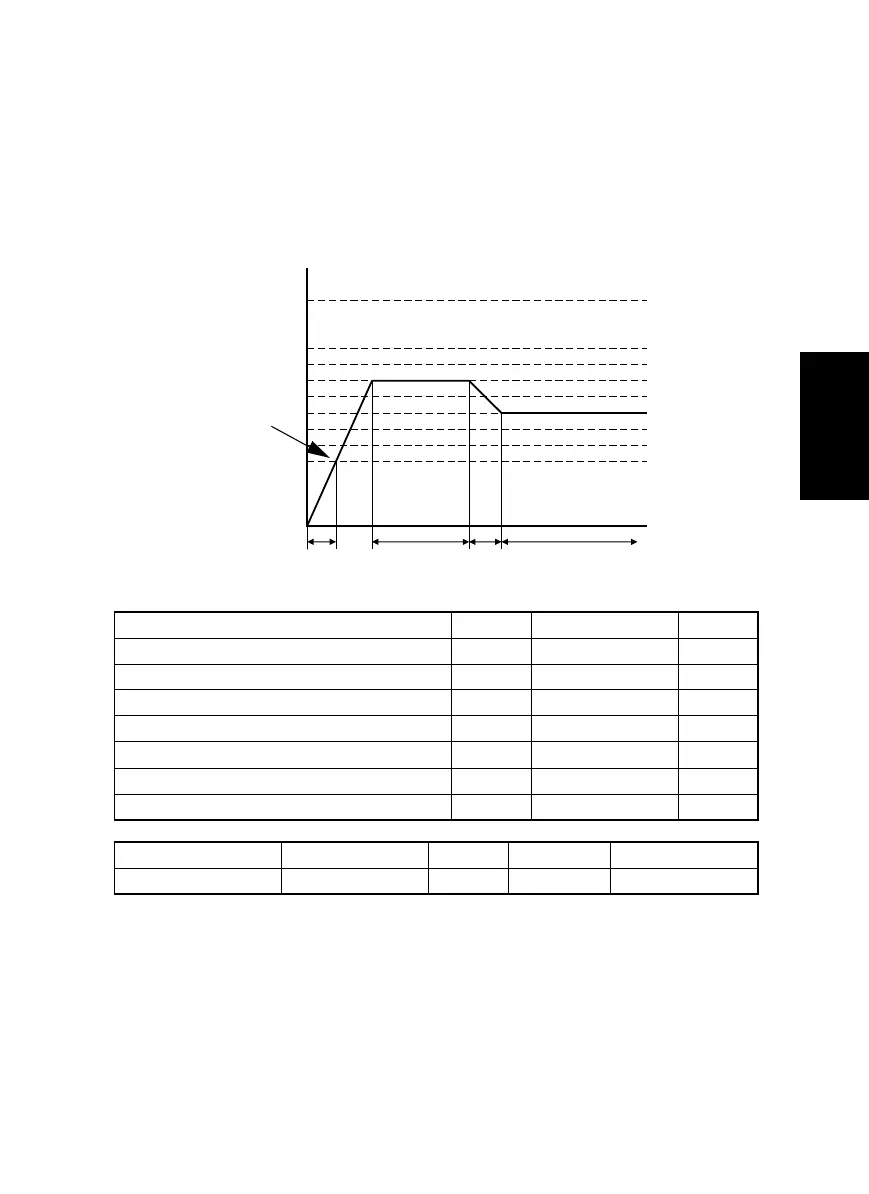

(˚C)

155

170

180

190

30 sec.

or less

Mode 1

5 min

Mode 2

1 min

Mode 3

200

<Temperature Control in Standby

4021M513CA

Warm-up completed

Loading...

Loading...