•

•

5.5.5 Master/slave mode – defrost synchronisation via CAN bus

All controller types versions >= V4.00

Requirements

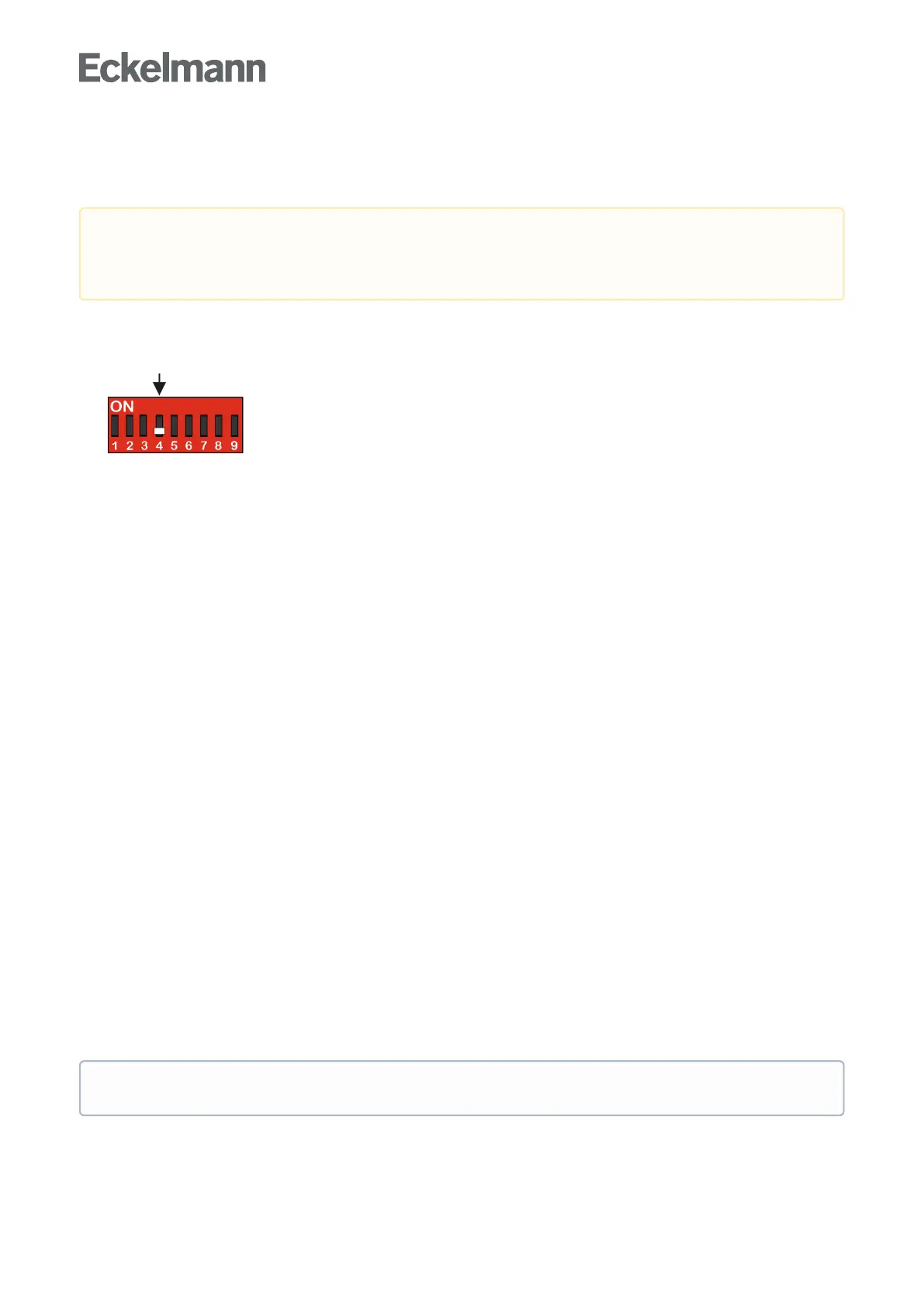

Setting of the DIP switch S3, coding switch 4 must be set to OFF;fordetails,seechapterSetting of the

controller type and master/slave mode.

Software settings, see below for details.

Function Description

The master/slave mode is used for refrigerated cases, for which the operation of multiple evaporators can result

inreciprocalicingoftheevaporatorswithoutfurtherprotectivemeasures.

This problem is prevented due to the defrost synchronisation in master/slave mode. All refrigerated cases and

case zones defrost simultaneously and then switch to cooling together. For this type of master/slave mode,

multiple involved controllers are synchronised via the CAN bus.

The master/slave defrost covers the following function: Following a joint defrost, a group of controllers only

switches back to cooling when all the controllers have completed their respective defrost. Therefore, the

transition from defrost to cooling operation is synchronised for all the case controllers in a defrost group.

The case controllers in the defrost group are divided into one defrost master and the defrost slaves. The defrost

master sets the defrost start, and at the end of the process, enables cooling again. All the other defrost

participants (when existing) are called defrost slaves and follow the instructions of the defrost master. Several

independent defrost groups can be realised, i.e. a number of defrost masters who each administer an arbitrary

number of defrost slaves. In addition to the defrost groups, further controllers entering defrost within the system

canexistindependentlyofthegroups.

The size of the defrost groups as well as the number of defrost groups is only limited by the maximum number

of participants in the E*LDS system.

Execution or sequence of the master/slave defrost via the CAN bus

A defrost is initiated at the master. From this point in time, all the slaves enter a defrost. As long as any of the

participants(slavesorthemaster)isstillindefrost,noneofthecontrollersinvolvedwillswitchtocooling.

f the defrost end temperature has been reached at one of the controllers, this controller sets its own defrost

relaytoOFF,butremainsinthedefroststateanddoesnotchangetothecoolingstate.

When all controllers involved have reached the end of the defrost cycle (whether via the safety time or via the

defrost termination temperature), they all return to the "cooling" state together.

Thesafetytimesetatthemasterandanywaitingordrippingtimesetatthemasterisalsousedbytheslaves.

Configuration / parametrisation of master/slave defrost via CAN bus

The controllers must be configured so that defrosting can take place. In the case of the master, a defrost is

activated via the internal clock, the external contact or via manual defrost (CAN/local). The master, with respect

totheparameter“M/S Abt Fkt”mustbesetto “Master”(menus2-2-1and2-2-2).Theparameter“M/S CAN Adr.”

is of no relevance for the master.

Damage to the installation and stock loss!Whenusingthisfunction,itmustbeensuredthat

incorrect parametrisation does not result in simultaneous defrost and cooling of the synchronised

refrigeration points.

Itisrecommendedtosettheparameter“M/S CAN Adr.”onthemasterto“—“.

Loading...

Loading...