101

EN

GSL

Lower gas flow rate limit

Setting range: 0.5 - 30.0 l/min

Factory setting: 7.0 l/min

GSt

Maximum duration of gas flow deviation

Setting range: off, 0.1 - 10.0 s

Factory setting: 2.0 s

GSF

Gas factor sensor

dependent on the shielding gas used

(only in conjunction with the OPT/i gas controller option)

Setting range: auto, 0.90 - 20.0

Factory setting: auto

(the correction factor is automatically set for standard gases from the Fronius welding da-

tabase)

Process parame-

ters for electrode

setup

The following process parameters can be set and displayed for manual metal arc welding

(STICK):

I-S

Starting current

For setting the starting current

Setting range: 0 - 200%

Factory setting: 150%

Hti

Starting current time

For setting the length of time for which the starting current is to be active

Setting range: 0.0 - 2.0 s

Factory setting: 0.5 s

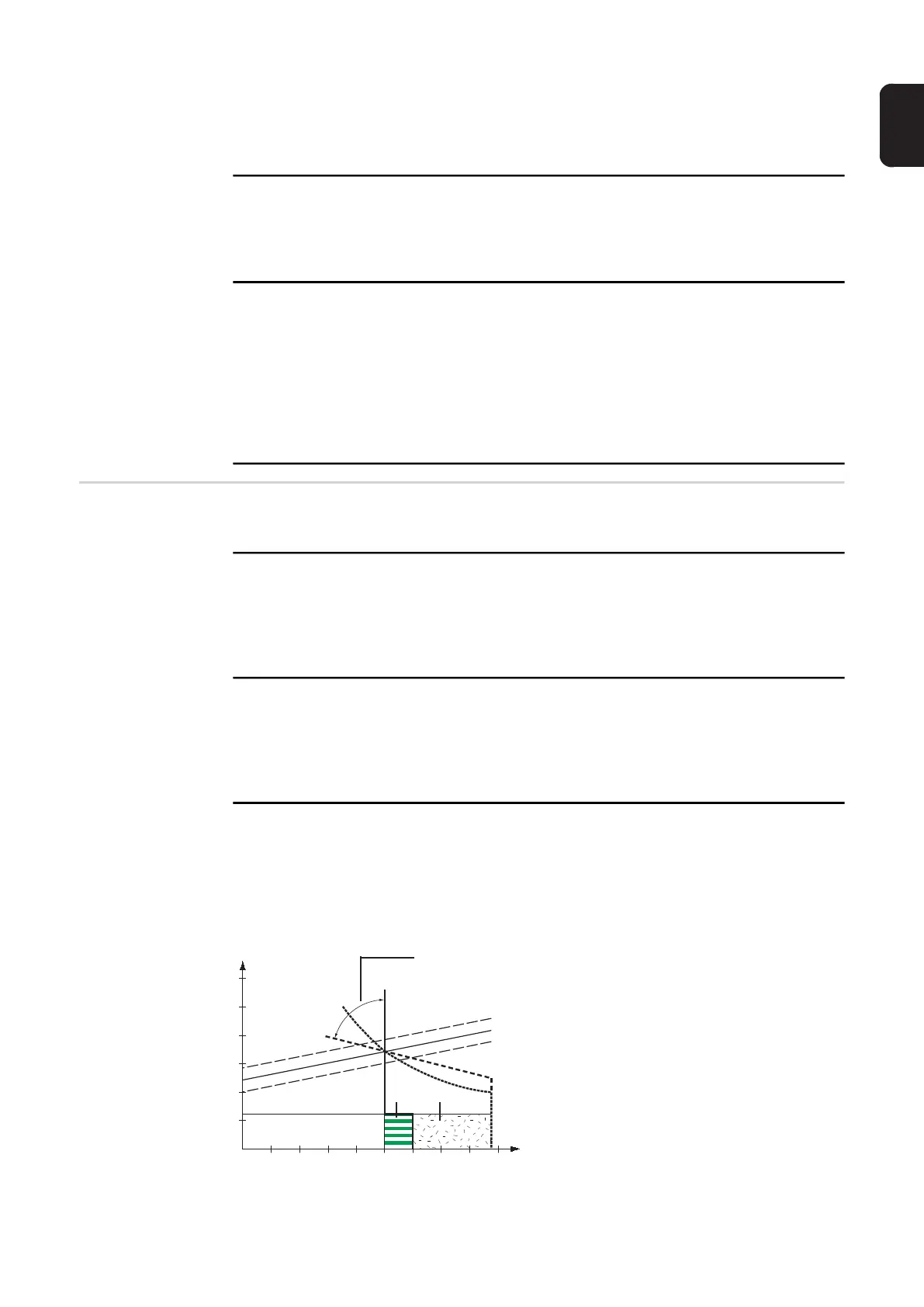

Eln

Characteristic

For selecting the electrode characteristic

Setting range: I-constant / 0.1 - 20.0 A/V / P-constant

Factory setting: I-constant

(1) Load line for rod electrode

(2) Load line for rod electrode where

arc length is increased

(3) Load line for rod electrode where

arc length is reduced

(4) Characteristic where "I-constant"

parameter is selected (constant

welding current)

(5) Characteristic where "0.1 - 20" pa-

rameter is selected (drooping cha-

racteristic with adjustable slope)

(6) Characteristic where "P-constant"

parameter is selected (constant

welding power)

0040 200100 300 I (A)

U (V)

con - 20 A / V

(4)

(5)

(6)

(7) (8)

(1)

(2)

(3)

Loading...

Loading...