68

SL2

Slope 2: the welding current is steadily lowered until it reaches the final current

GPo

Gas post-flow

A detailed explanation of the parameters can be found in the section headed "Process pa-

rameters"

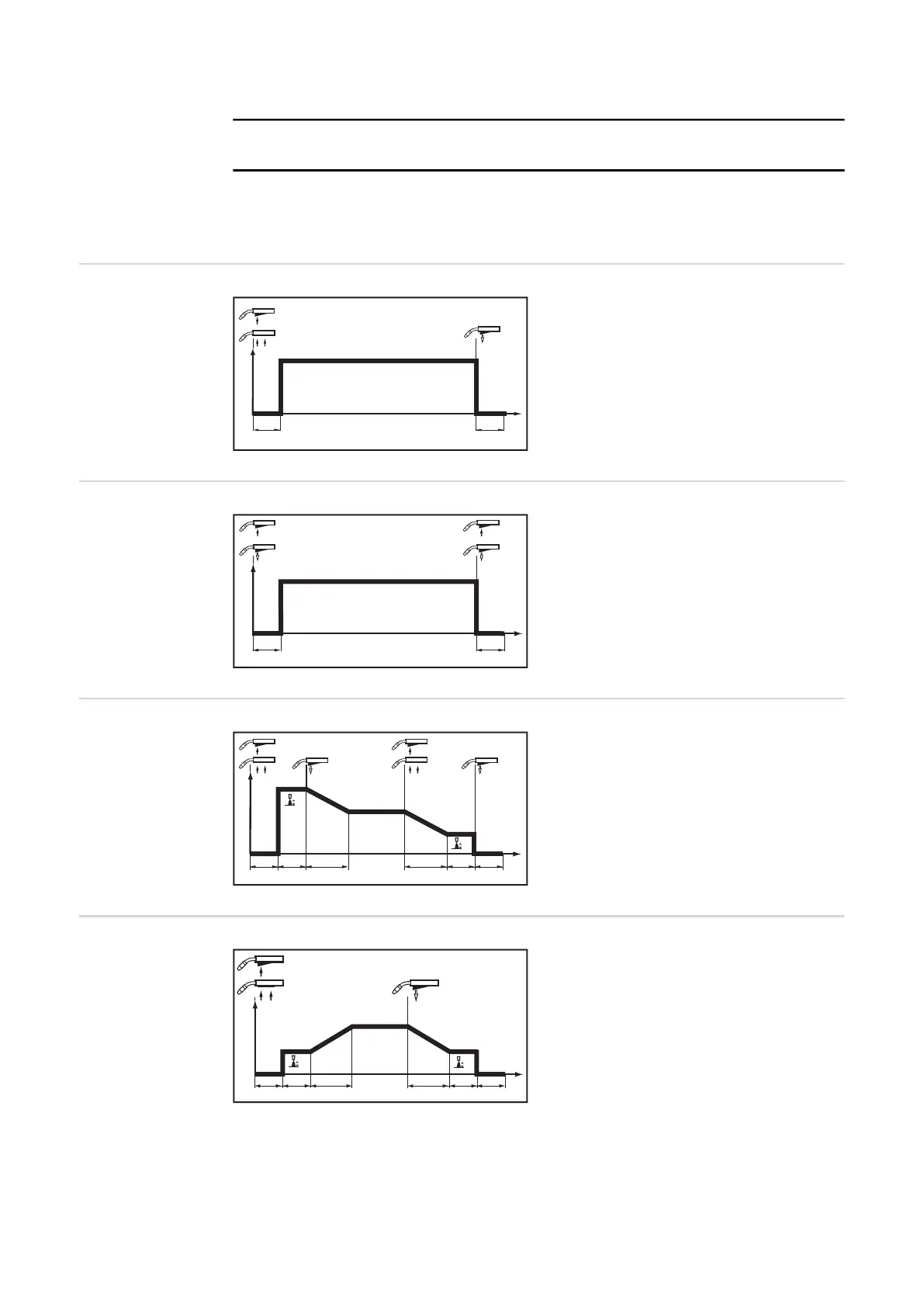

2-step mode "2-step mode" is suitable for

- Tacking work

- Short weld seams

- Automated and robot welding

4-step mode

"4-step mode" is suitable for longer weld

seams.

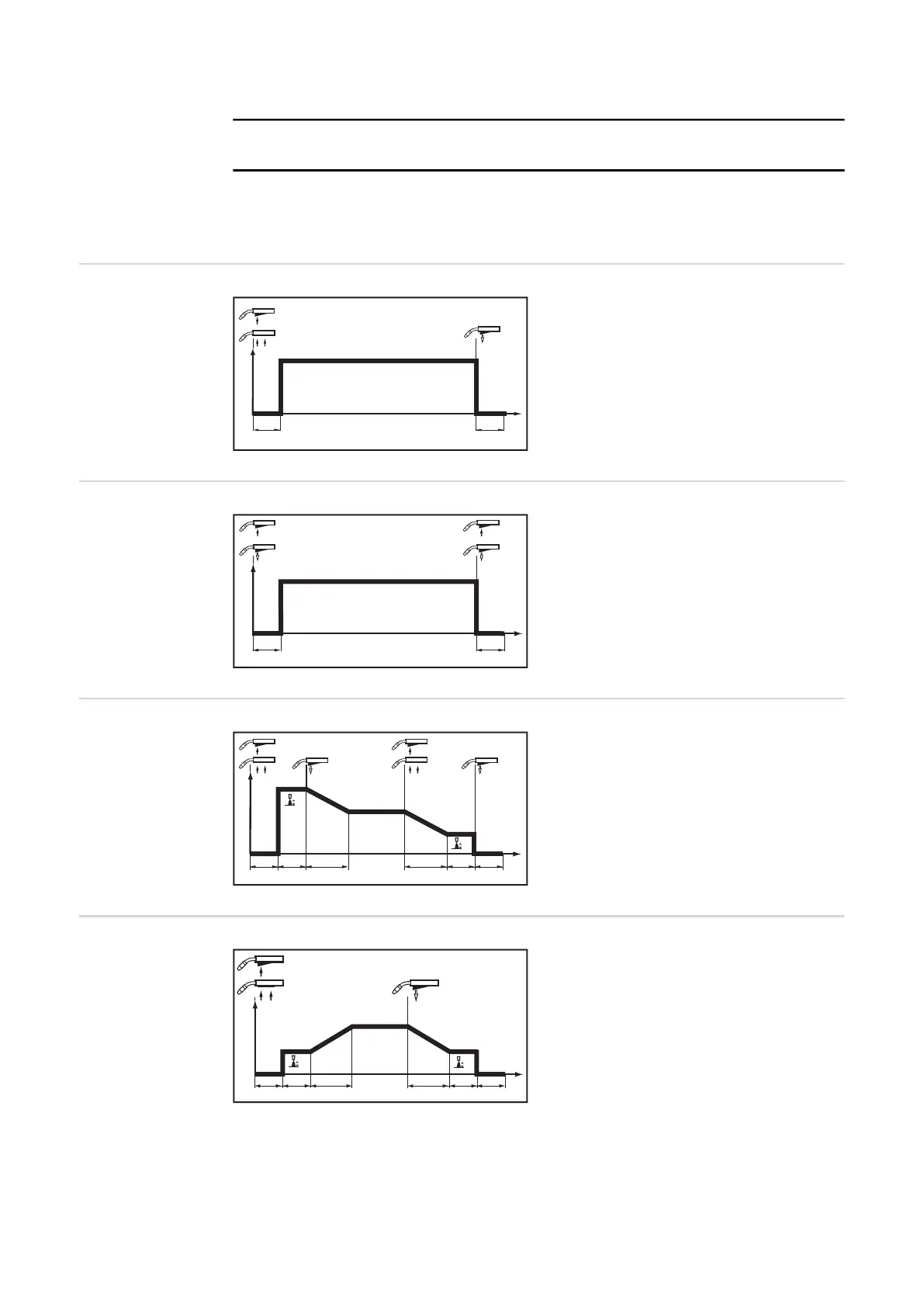

Special 4-step

mode

"Special 4-step mode" is particularly suitab-

le for welding aluminium materials. The

special slope of the welding current curve

takes account of the high thermal conducti-

vity of aluminium.

Special 2-step

mode

"Special 2-step mode" is ideal for welding in

the higher power range. In special 2-step

mode, the arc starts at a low power, which

makes it easier to stabilise.

t

I

+

I

GPr GPo

t

I

+

I

GPr GPo

+

I

t

I

GPr GPo

I-E

SL1t-S

I-S

SL2

+ +

S

E

t-E

I

I-S

I-E

+

I

S

E

GPr GPoSL1 SL2

t

t-S t-E

Loading...

Loading...