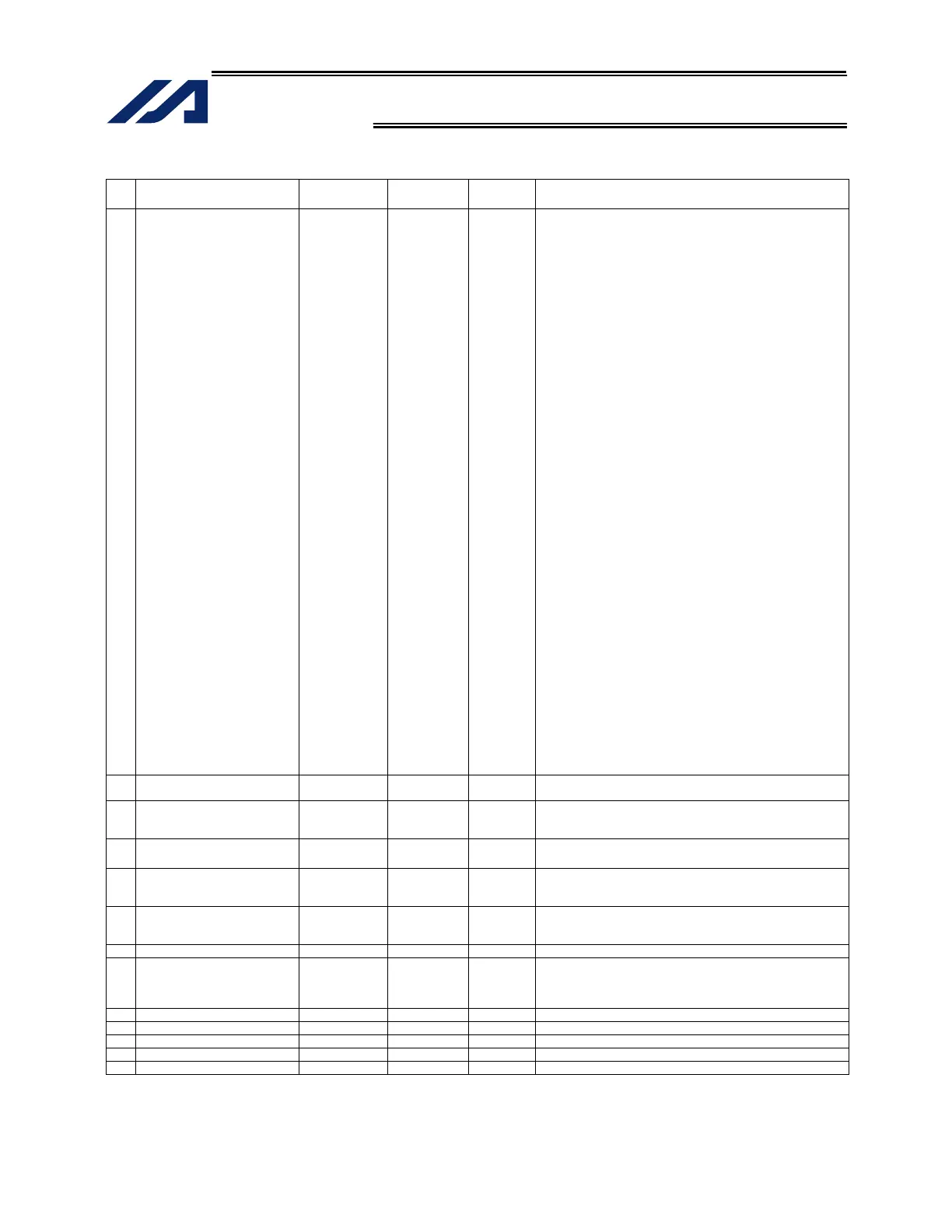

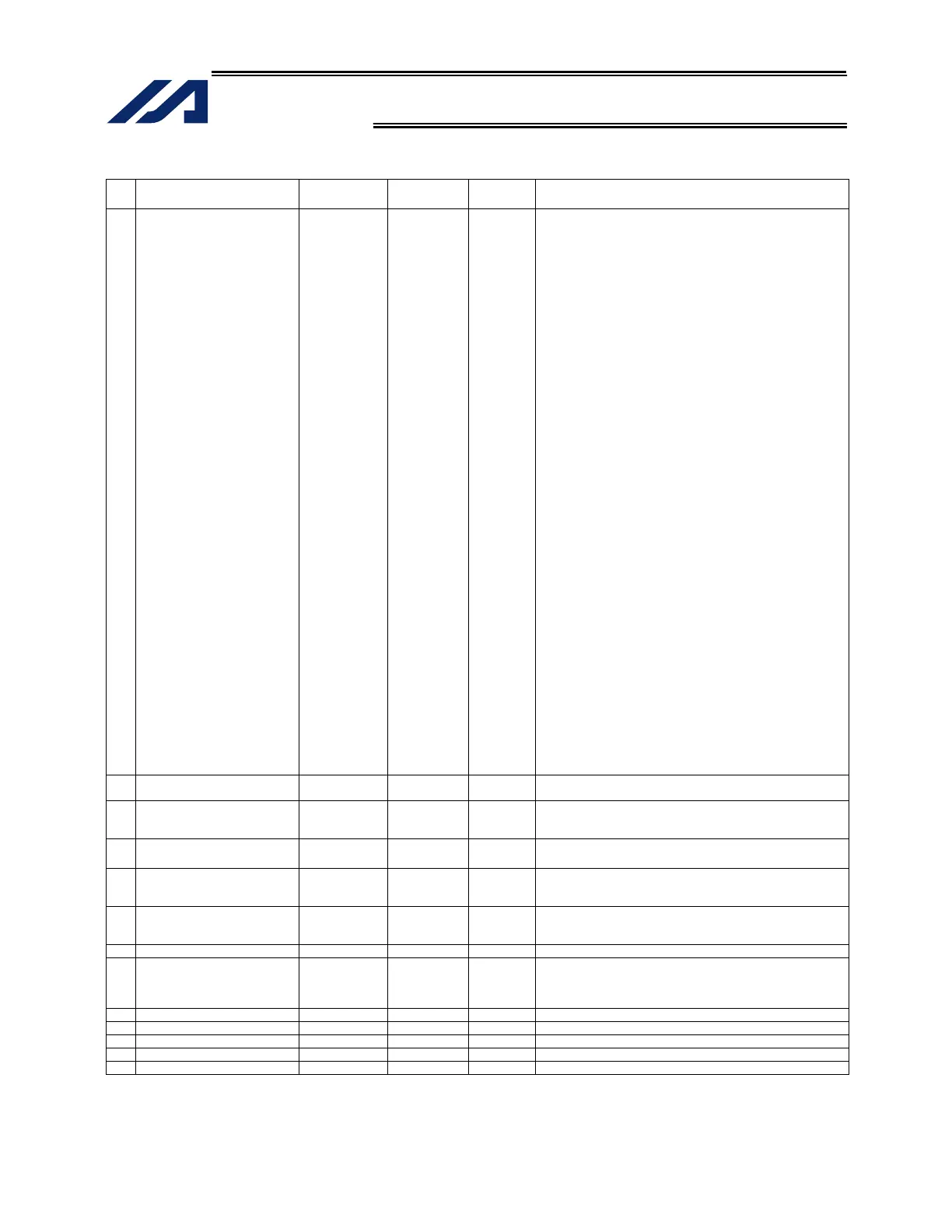

428

INTELLIGENT ACTUATOR

Appendix

Axis-Specific Parameters

No Parameter name

Default value

(Reference)

Input range Unit Remarks

52 Synchro setting bit pattern

1

0 0H to

FFFFFFFFH

* Effective only when specified for the synchro slave

axis. (Main application version 0.62 or later)

Bits 8 to 11: Selection of use of phase Z of the synchro

slave axis during home return of the incremental

encoder (INC-INC control)

(0: Do not use phase Z of the slave axis

1: Use not use phase Z of the slave axis)

* If phase Z of the slave axis is used, the following

parameters of the slave axis will become effective:

“Axis-specific parameter No. 21, Offset travel distance

at home return”

“Axis-specific parameter No. 12, Home preset value”

* Adjustment method when phase Z of the slave axis is

used

[1] Complete a home return in the synchronized

mode.

Ignore the “Error No. D0A, Driver overload error”

that generates upon completion of home return.

If an “Error No. C9C, Defective phase-Z position

error” generates, the relationship of the installed

positions of both synchro axes must be adjusted.

If an “Error No. C72/D6B, Overrun error” generates,

adjust the relationship of the installed positions of

both synchro axes or set “Axis-specific parameter

No. 15, Overrun-sensor input polarity” to “0 (Do not

use)” and stop using the overrun sensor.

[2] Turn the servo OFF by actuating an emergency

stop.

[3] Align the physical position relationship of the

synchro master axis and slave axis and then read

off their present position coordinates.

[4] Calculate the value of “present position

coordinates of synchro slave axis – present

position coordinates of synchro master axis” and

set the calculated value in “Axis-specific

parameter No. 21, Offset travel distance at home

return” for the synchro slave axis (Exercise

caution that unit conversion is required in the

above calculation.)

[5] Write the data to the flash ROM, and then

execute a software reset or power ON reset of the

controller.

* Effective only when specified for the synchro slave

axis. (Main application version 0.63 or later)

53 Setting bit pattern 1 of each

axis

0 0H to

FFFFFFFFH

54 Travel distance for push

stop detection at home

return

20 1 to 99999 0.001 mm

Used to confirm pushing action at the time of home

return.

55 Travel distance for push

stop detection at positioning

30 1 to 99999 0.001 mm

Used to confirm pushing action according to the PUSH

command.

56 Push-abort deviation ratio

at home return

2000 1 to 99999 Deviation is compared against “Steady-state deviation

of push speed + Push-speed pulse speed x Abort

deviation ratio.”

57 Push-abort deviation ratio

at positioning

5000 1 to 99999 Deviation is compared against “Steady-state deviation

of push speed + Push-speed pulse speed x Abort

deviation ratio.”

58 Positioning band 100 1 to 9999 0.001 mm *Related information: Axis-specific parameter No. 52

59 Allowable deviation error

ratio

(Maximum speed pulse

ratio)

85 1 to 99 Deviation is compared against “Steady-state deviation

of maximum operating speed of each axis + Pulse

speed of maximum operating speed of each axis x

Allowable deviation error ratio.”

60 Position gain 30 1 to 9999 /s

61 FAG 0 0 to 999

62 Synchro FB gain 77 0 to 1000

63 Stop special output range 1 0 to 9999 Pulse Invalid if “0” is set.

64 Stop special output value 1 0 to 999 DRVVR

Loading...

Loading...