Model 250

Printer Applicator

Operators/Technical Manual Section Six

Section 6 Page 14 of 20

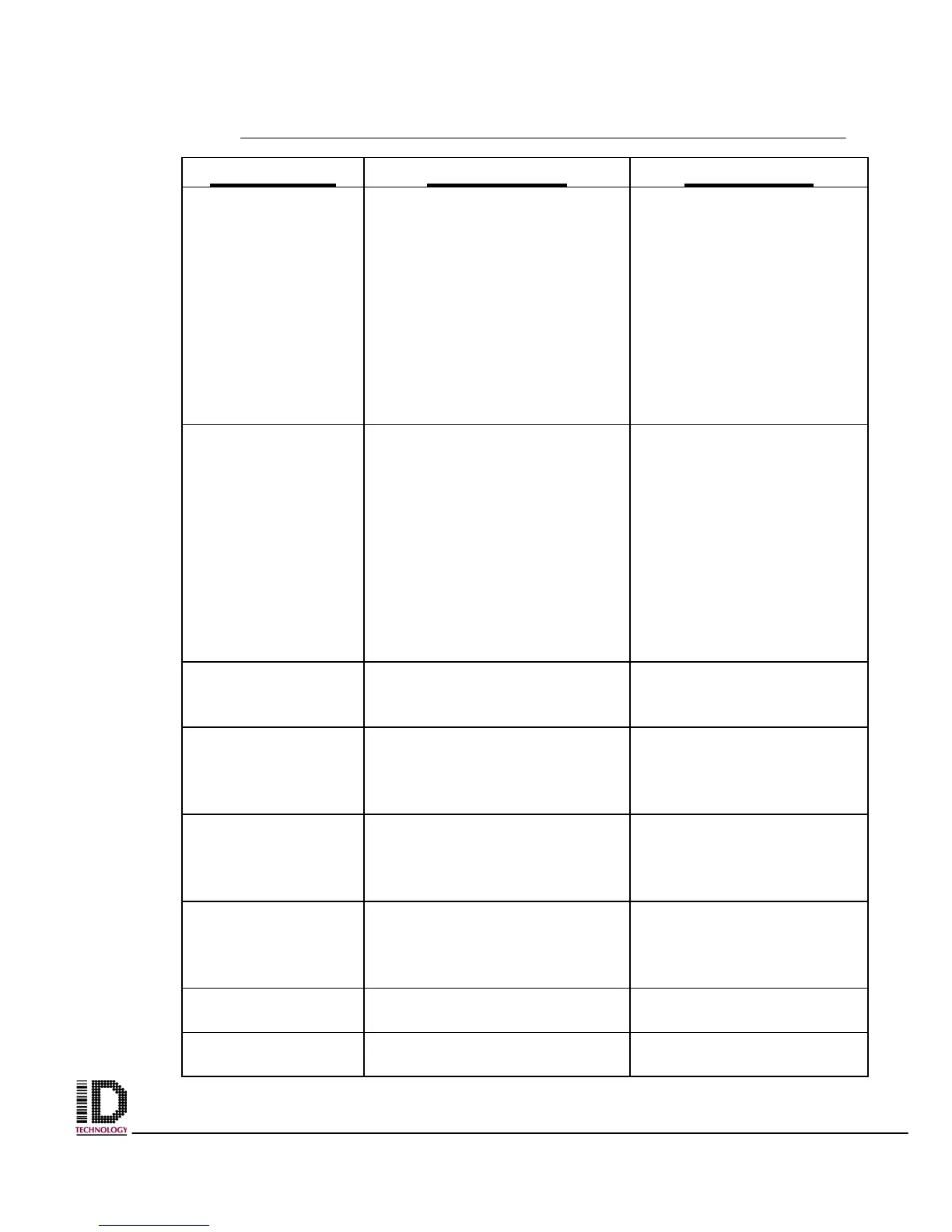

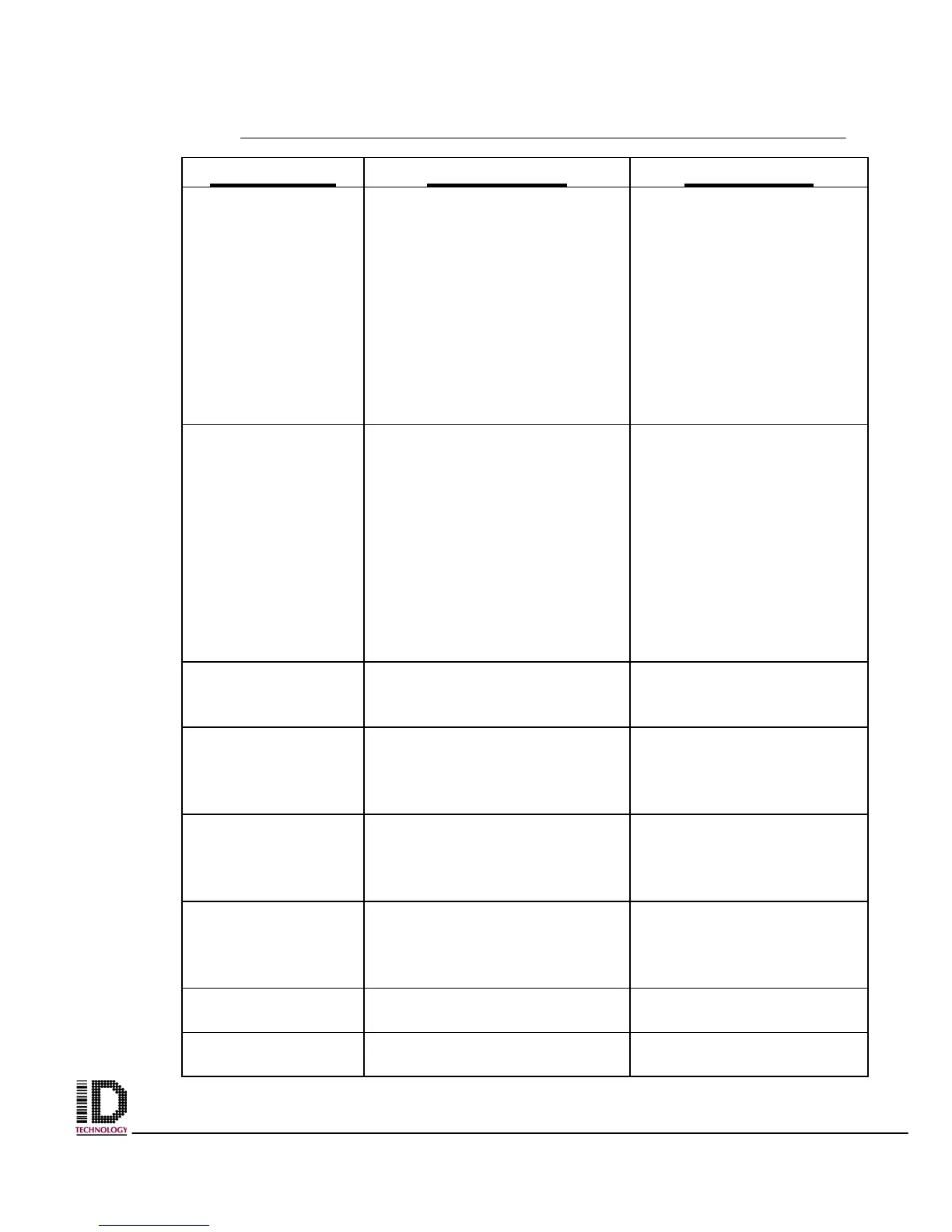

SYMPTOM DIAGNOSIS SOLUTION

Misregistration or

skips labels.

1. Label Sensor is not

positioned correctly.

2. Label Sensor not

calibrated.

3. Media does not meet

specifications.

4. Waste take-up tension out

of adjustment.

Adjust Label Sensor.

Check sensor threshold.

Use media that meets

specifications

Correct

Vertical drift in top-

of –form

registration.

1. A plus or minus 0.5 mm

vertical drift is acceptable

due to the different

tolerances of the

mechanical parts and

printer modes.

2. Label Sensor out of

Calibration.

3. Platen dirty.

See Sato Manual.

Recalibrate sensor

threshold.

Clean Platen.

Long tracks of

missing print on

several labels.

Print element damaged. Replace printhead.

Poor print quality. 1. Printhead dirty

2. Printhead adjustments

incorrect.

Clean printhead.

Perform required

adjustments.

Truncated print, no

print, or Feed

button operates

incorrectly.

Belt slipping on platen roller Adjust or replace belt.

Printer fails to

respond to

communication No

DATA LED activity.

Incorrect communication port

selection.

Verify the proper port or

communications interface

type configuration.

ERROR lights on or

flashes on printer.

Check for message in LCD. Correct. Cycle power if

necessary

RIBBON light

flashes on printer.

Ribbon near end Replace ribbon with full

roll.

Loading...

Loading...