1

Chapter 10 MAINTENANCE AND CHECK

¾ Rotating section

z Oiling gears

Apply grease evenly to the tooth surfaces of the main shaft drive gear and the encoder

drive gear with a spreader or brush. Oiling in short intervals is more effective to prevent

the gears from wear and tear and extend their service life, but oil at least every six

months.

Use the grease of Mobilux 2 of Mobil Oil.

z Driving motor

1) Attenuator

Greasing is not necessary unless there is oil leakage.

2) Motor

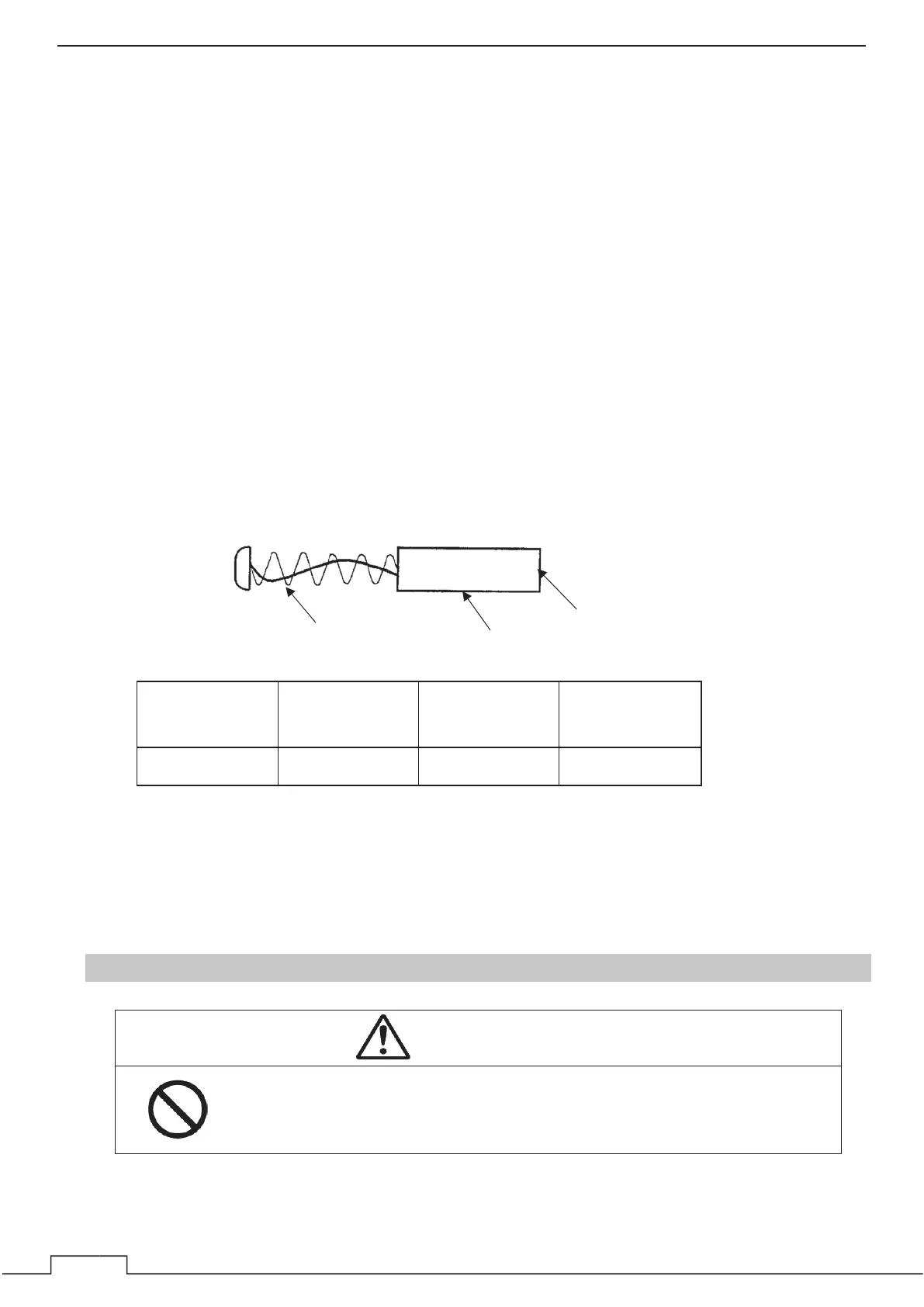

The life span of the brush itself is 2000 hours. When the brush is worn out to a half of

the entire length, replace it.

The communicator must be kept clean all the time. If carbon dust is stuck and cannot be

removed with a dry cloth, polish the section with sand paper of No.150 to 400.

The carbon brush can be removed by removing the caps on both sides of the bottom of

the motor.

replacement carbon brushes

Scanner unit

model name

Item name Model name JRC code

JMA-3406 Carbon brush 54531-01 BRXP05247

z Mounting legs

Check the mounting legs and mounting bolts of the scanner unit case for corrosion at

intervals and maintain them to prevent danger. Apply paint to them once a half year

because painting is the best measure against corrosion.

10.2.2 DISPLAY NCD-2364

DANGER

When cleaning the display screen, do not wipe it too strongly with a dry

cloth. Also, do not use gasoline or thinner to clean the screen.

Failure to comply will result in damage to the screen surface.

Dust accumulated on the screen will reduce clarity and darken the video.

For cleaning it, wipe it with a piece of soft cloth (flannel or cotton).

Do not wipe it strongly with a piece of dry cloth nor use gasoline or thinner.

Carbon brush

Communicator contact side

Spring

Loading...

Loading...