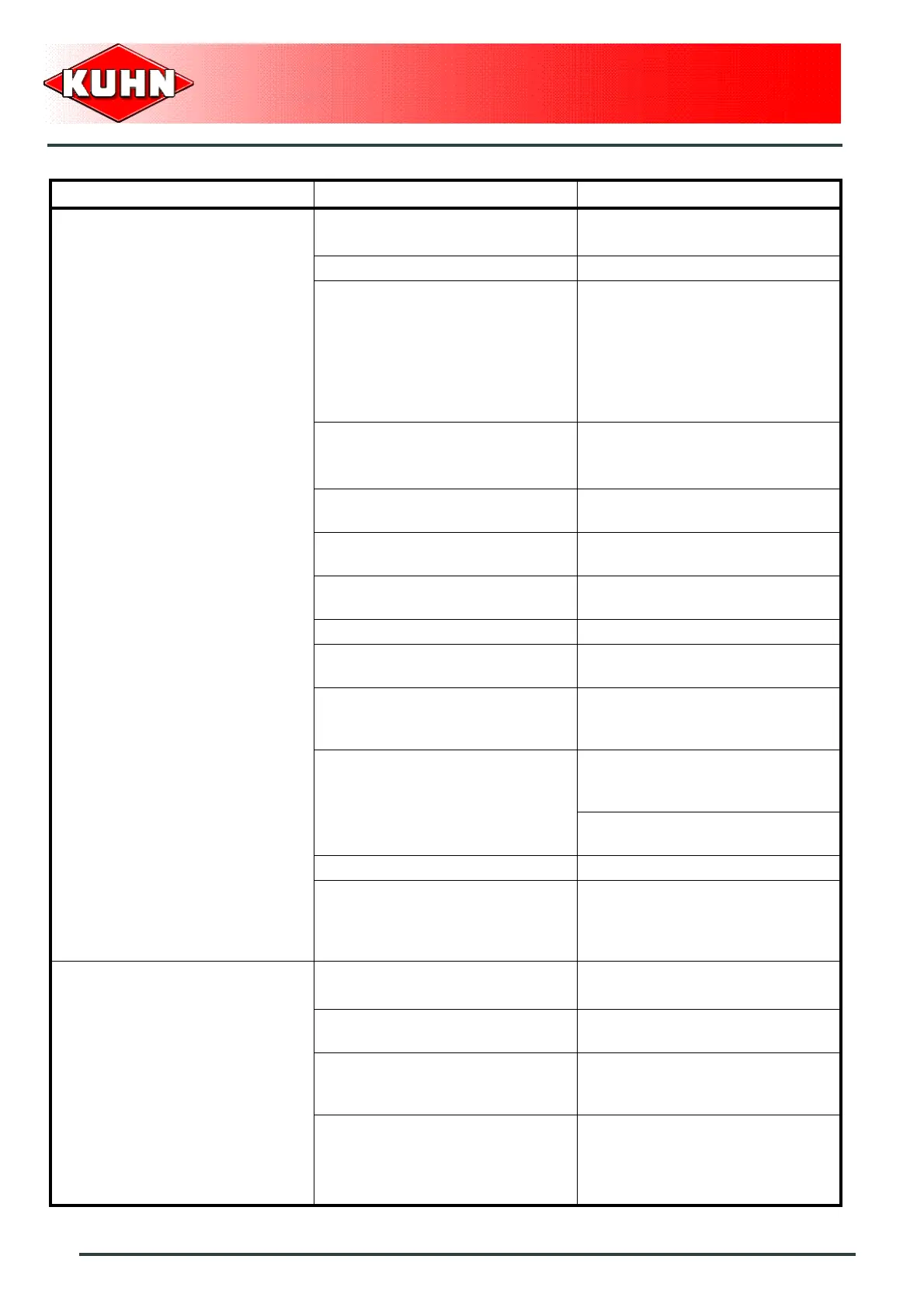

Precision Seed Drills

210

MAXIMA 2

Trouble shooting guide

Unevenness while sowing.

Inappropriate disk being used. Fit a disk to match seed size.

Incorrect selector adjustment. Adjust selector.

Seed variety or batch promote

poor placement.

Check improvement with

another variety.

(if possible send us a sample to

the factory in order to check

the problem with this type of

seed on our test rig and to

optimise settings).

Ground conditions.

Prepare ground correctly.

Moisture content must be

correct.

friction point in drive.

Check drive condition (gears,

sprockets and chains).

Incorrect gearbox setting.

Use ratio adapted to the

required population.

Excessive ground speed.

Adapt the forward speed to the

working conditions.

Worn opening disks. Replace opening disks.

Improper pressing and

covering adjustment.

Reposition them so they do not

interfere with seed positioning.

Incorrect seed drill horizontality

adjustment.

Adjust the 3rd point such that

the machine operates perfectly

level.

Seed transfer duct encrusted

and partialy blocked.

Clean the inside and do not

hesitate to replace it if

necessary.

Check for correct vacuum, re-

tension the belt if necessary.

Warped disk. Replace disk.

Drive wheels are not always in

contact with the ground.

Adjust spring adjustment in

order to limit the ground

pressure or add weights on the

frame.

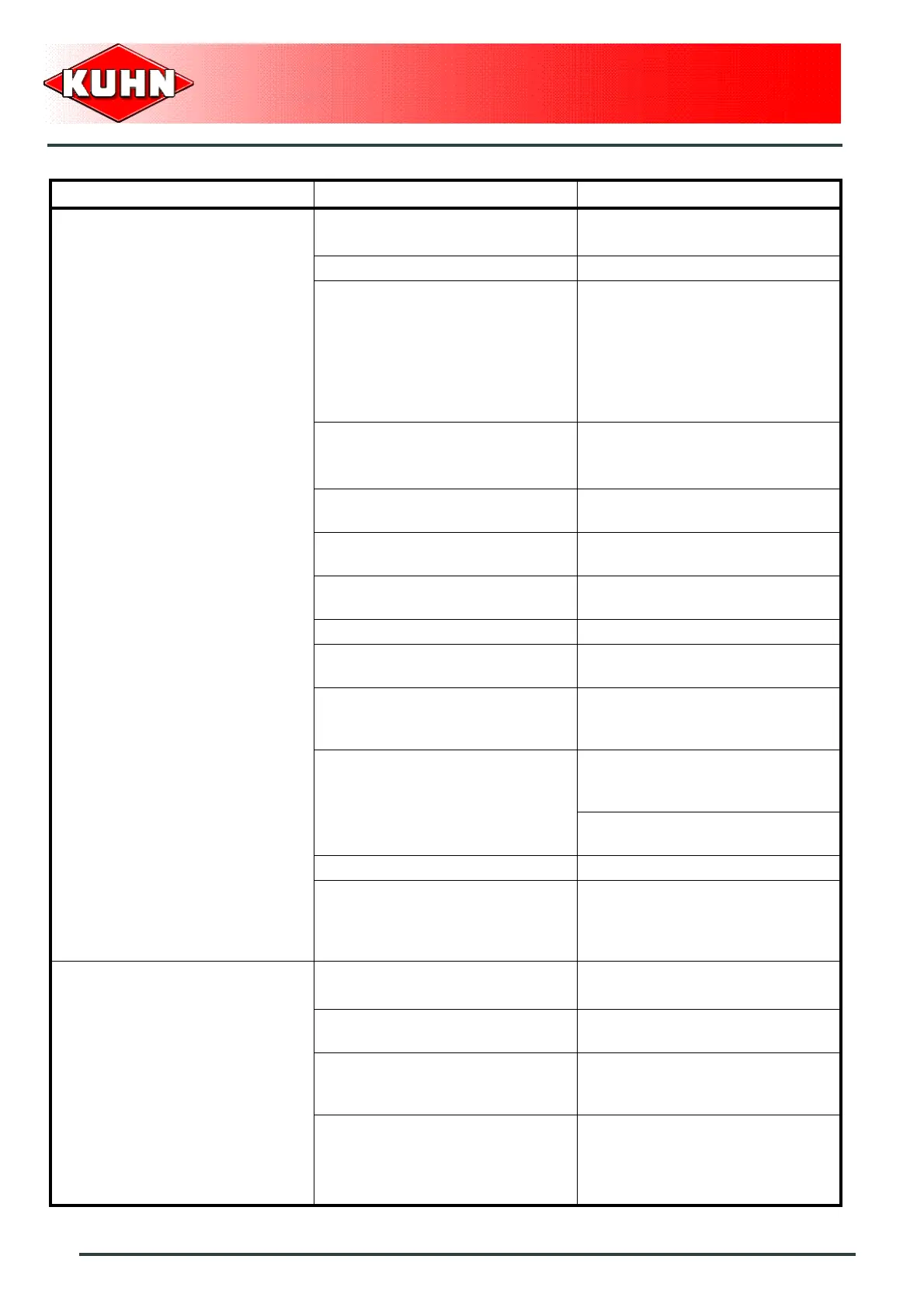

Uneven sowing depth.

Ground too lumpy or too stony. Prepare ground correctly.

Excessive ground speed.

Adapt the forward speed to the

working conditions.

Incorrect seed drill horizontality

adjustment.

Adjust the 3rd point such that

the machine operates perfectly

level.

Disks have difficulty in

penetrating the ground.

Install ground pressure springs

or fit a pre-cutting disk.

Problem Cause Remedy

Loading...

Loading...